Exploration and research progress of shale gas in China

Gng-yi Zhi , Yu-fng Wng ,*, Zhi Zhou , Shu-fng Yu Xing-lin Chen Yun-xio Zhng

a Oil and Gas Survey, China Geological Survey, Beijing 100029, China

b Unconventional Oil and Gas Geology Laboratory, China Geological Survey, Beijing 100029, China

ABSTRACT

There are three types of shale gas resources in China. The resources are present in large amounts and are widely distributed. Marine facies, transitional facies and continental facies resources each account for a third. Based on resource distributions, there are many wells penetrated into the Sinian, Cambrian,Ordovician, Silurian, Devonian, Carboniferous and Permian strata of the Yangtze plate and its periphery,the North China Craton and the Tarim Basin. Many years of exploration have indicated that the marine Silurian Longmaxi shale gas is widely distributed in south China and has been industrialized in its production in the Sichuan basin. The shale gas from the Cambrian Niutitang Formation and the Sinian Doushantuo Formation are important discoveries in Yichang, Hubei and Zhenba, Shanxi. There are also shale gas resources found within transitional facies and continental facies in different areas in China. The"two element enrichment theory" has been summarized during the exploration process of Silurian marine shale gas in the Sichuan Basin. In addition, horizontal drilling and fracturing technologies up to 3500 m in depth have been developed. Based on the understanding of shale gas accumulation in a complex tectonic zone outside the Sichuan basin, a preliminary summary of the formation of the "converse fault syncline control reservoir" and "paleo uplift control reservoir" model has been constructed. The dominant theory of"Trinity" shale gas enrichment and the high yield of the "deep water Lu Pengxiang sedimentary facies belt,structural preservation conditions and overpressure" is summarized. Guided by the above theories. Anye1 well in Guizhou and Eyangye1 well in Hubei were drilled. "Four storey" oil and shale gas is found in the Permian Qixia group, the Silurian Shiniulan Formation, the Longmaxi Formation and the Ordovician Baota Formation in Anye1 well. Good shale gas has been gound in the Cambrian Niutitang formation inian Doushantuo formation in Eyangye 1well. This paper aims to summarize and review the main progress, theoretical technology and problems of shale gas exploration and development in recent years in China, and predicts the future exploration and development direction for shale gas and possible exploration areas.

Keywords:

Shale gas

Exploration

Enrichment

Accumulation

Theoretical technology

1. Introduction

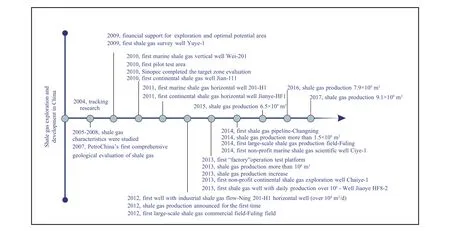

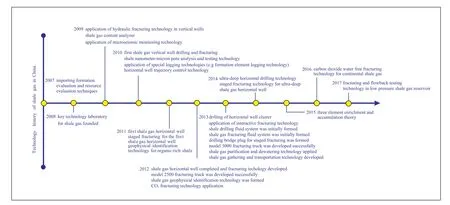

The shale-gas revolution in the United States has not only transformed the energy structure around the entire world but has also led to great improvements in theoretical understanding and the exploration and development technologies of the oil and gas industry. In the USA, from the first shale-gas well being discovered in 1821, to the breakthroughs in massive production capacity that began after 2000, it has taken a long time to make break-throughs in theoretical understanding and innovate development technologies (Zeng SJ et al., 2013; Kuuskraa V et al., 2013;Liu HF et al., 2012; Luo ZX et al., 2012; Zhou SW et al.,2012; Zhao Q et al., 2008; Li SZ et al., 2010; Zhang XL et al.,2013; Jiang FJ et al., 2012; Zhang JC et al., 2009; Zhao Y et al., 2013; Zhang SX et al., 2013; Zhao JZ et al., 2011; Yin PF et al., 2011; Yang ZH et al., 2013). In a nutshell, three main technological innovations played key roles in the success of the shale-gas revolution in the USA: Ⅰ, the innovation in the continuous oil and gas reservoir-forming geological theory,based on the micro-nano porosity system; Ⅱ, the innovation in the core technology, creating "artificial permeability" by volume-fracturing horizontal wells; Ⅲ, the innovation of the low-cost "well factory" development model. Since 2004, on the basis of lessons learned from the experiences of the US in shale-gas exploration and development, evaluation of the shale-gas resource potential and trials on shale-gas exploration and development have begun all over China.Shale-gas exploration and development in China has basically undergone the path of "pioneering with scientific researchresource evaluation-market opens up-planning-construction of demonstration bases (Fig. 1)". During this journey, China had to face one failure after another, while learning lessons from each of the failures, and eventually a breakthrough and commercialized development was achieved in the marinefacies Silurian Longmaxi Formation in the Sichuan Basin.Afterwards, a few shale gas development bases were built in Jiaoshiba, Fuling, Chongqing, Weiyuan, Changning, Sichuan,Zhaotong, Yunnan, and Fushun-Yongchuan etc., and progressively the marine-facies shale-gas reservoir-formation and theoretical knowledge enrichment and the horizontal-well completion fracturing technology system finally came into being in South China (Dong DZ et al., 2013; Mi HY et al.,2010; Jia FX et al., 2013; Li JZ et al., 2012; Dong DZ et al.,2011; Li SZ et al., 2013; Zeng FH et al., 2013; Dong DZ et al., 2012; Yan W et al., 2013; Wang LS et al., 2011; Wang SQ et al., 2013; Zuo XM et al., 2010; Chen SB et al., 2010;Wang XZ et al., 2013).

Among the various types of shale-gas resources in China,apart from those in the marine-facies Longmaxi Formation,shale gas exploration in the transitional facies and the continental facies have progressed slowly and have not made any commercial breakthroughs so far, only achieved the theoretical knowledge of reservoir-formation, and the exploration and development technology system on the continental and transitional facies shale-gas. In addition,further researches are required to commercialize the development of extrabasinal marine shale gas, due to countless challenges, including far more ancient ages,intensive tectonic transformation, normal-pressure formations,reservoirs being exceptionally deep, and excessive thermal evolution etc. In recent years, the Survey Center for Oil and Gas Resources (SCOGR) of the China Geological Survey(CGS) has conducted numerous basic geological surveys and researches into shale gas resources in different formations and systems, such as Longmaxi Formation, Niutitang Formation,Doushantuo Formation, Dalong-Longtan Formation, and the Devonian-Carboniferous System, summarized to gain knowledge on reservoir formation theories and main enrichment and high-yield controlling factors on the five types of shale gases, and, building on these, guiding the deployment of shale-gas parameter wells, and making a series of breakthroughs in understanding, have led and promoted the progress of China’s shale-gas exploration and development.

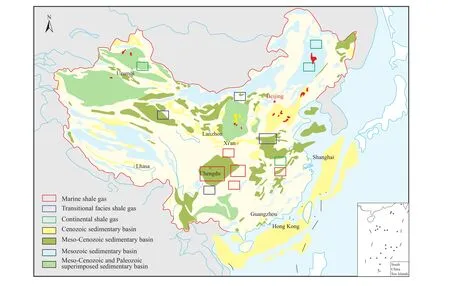

2. Distribution, types and advancements in shale-gas exploration and development in China

China has an abundance of shale gas resources. According to an evaluation on shale gas resources carried out by the Ministry of Land and Resources, there are 134×1012m3shalegas geological resources, of which 25×1012m3are technically mineable resources, including a variety of types such as those in marine, continental and transitional facies, and they are distributed in formations of Paleozoic, Mesozoic and Cenozoic Erathems (Liu HL et al., 2010; Zou CN et al., 2010;Zou CN et al., 2016; Zhang K et al., 2009; Zou CN et al.,2011; Zhang JC et al., 2008; Li YX et al., 2012; Hao ZG et al., 2017; Cao Q et al., 2015; Wang DF et al., 2015; Liu B et al., 2015; Feng MY et al., 2015; Pu BL et al., 2015). Thus far,China has made breakthroughs in the exploration and development of shale gas, and as of the end of 2017, has an accumulated geological reserve of shale gas of 7643×108m3.The cumulative shale gas yield is 180×108m3. China has made great breakthroughs and discoveries in the exploration and development of shale gas in marine, transitional and continental facies, and has basically developed five main regions to produce shale gas: Fuling, Changning, Weiyuan,Zhaotong and Yanchang (Fig. 2).

Fig. 1. Timeline for shale-gas exploration and development in China.

2.1. Breakthroughs in marine facies shale-gas exploration and development achieved in multiple places

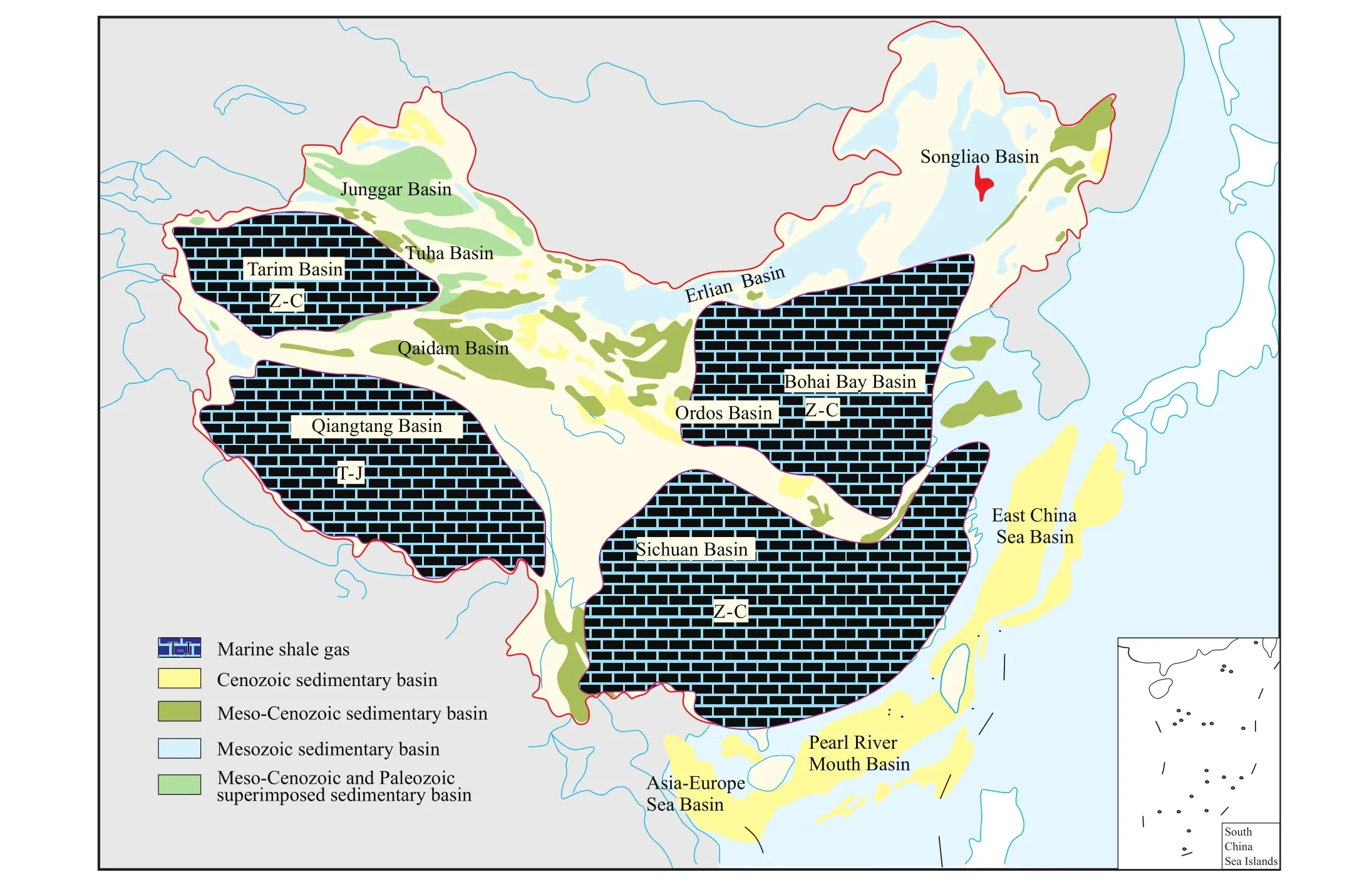

The marine facies shale-gas resources of China are mainly distributed across the Yangtze Plate in South China, the Tarim Basin in West China, North China and Qiangtang in Qinghai-Tibet Plateau (Fig. 3), mainly including 15 shale formations,primarily including the Doushantuo Formation, Niutitang Formation and Wufeng-Longmaxi Formation in Sinian,Cambrian, Ordovician-Silurian and Carboniferous-Permian in South China; the Hongshuizhuang Formation, Xiamaling Formation and Ordovician Pingliang Formation of the Mesoproterozoic and Neoproterozoic in North China; the Tueryusi Formation, Saergan Formation and Yingan Formation of the Ordovician in the Tarim Basin; and the Xiaochaka Formation, Buqu Formation and Xiali Formation of the Jurassic in the Qiangtang Basin. The marine facies organic-rich shale is present over wide regions, large in thickness for monolayers, high in organic carbon content,high in thermal evolution, rich in brittle minerals and welldeveloped micro-nano porosities, which is considered as the most promising shale gas exploration target.

Fig. 2. Distribution of 5 shale gas production regions in China.

Fig. 3. Distribution of marine facies organic-rich shale in China.

In China, the first great breakthrough in shale gas exploration and development was made in the marine facies Silurian Longmaxi Formation in the Sichuan Basin. Since 2009, petroleum companies such as Sinopec and CNPC,taking the lead in exploring shale gas in the Sichuan Basin,have made shale-gas discoveries and breakthroughs in Jiaoshibao, Fuling, Changning-Weiyuan, Fushun-Yongchuan,and Zhaotong, Yunnan successively, and established largescale capacity development bases by constructing demonstration zones, Fuling shale gas field so far being the largest one in China. As of the end of 2017, Sinopec had developed the first large shale gas field on a large scale in the Fuling Block, where 6008.14×108m3of geological reserves was proved cumulatively, 133 platforms for demonstration bases were built, 406 shale-gas wells were drilled, of which 260 are currently operating, the capacity of 100×108m3was developed and 149.21×108m3shale gas in total was produced.Following drilling and fracturing of the wells Dingye 2HF and Nanye 1HF, the exploration of Fuling shale gas is gradually being expanded to regions such as Nanchuan,Wulong and Pengshui, Chongqing etc. To open up a second development base.

CNPC has made a succession of high-yield shale-gas breakthroughs in the Longmaxi Formations of Changning and Weiyuan, Sichuan, and Zhaotong, Yunnan. The Wei 204 Well initially yielded 1.65×105m3/d after staged fracturing, the Ning 201 Well yielded 1.5×105m3/d during testing; the initial yield of Zhao 104 Well was 1.2×104m3/d, and the horizontal well YS108H1-1 delivered the highest industrial gas flow of 2×105m3/d. Breakthroughs in shale gas exploration were made in the Changning, Weiyuan and Zhaotong Blocks. In Weiyuan-Changning, Sichuan, 1.635×1011m3of geological reserves were proved cumulatively to be present, and the 25×108m3/year capacity infrastructure was developed. As of the end of 2017, there were 50 new platforms that began drilling, 230 wells being drilled, 192 wells with completed drilling and 154 wells cumulatively operating, the shale-gas yield was 28×108m3in 2016 and 30×108m3in 2017 in Chang ning, Weiyuan and Zhaotong, and it is predicted that the shale-gas yield will reach 1010m3in south Sichuan by 2020.

Second, enterprises that won the two rounds of shale-gas bidding have actively been exploring shale gas on the outside of Sichuan Basin. In the blocks such as Qianjiang,Chongqing, and Baojing, Hunan, the exploratory wells Zhuoye 1 and Baoye 1, both of which targeted the Longmaxi Formation of the Lower Silurian Series, also delivered better discoveries, with gas content up to 1-4 m3/t, of which Baoye 1 Well, after being transformed through fracturing, was tested to give the highest yield of 2000 m3/d, and the Longshen 2 Well reached the highest yield of 6000 m3/d. By tracking and analyzing the results from the shale-gas exploratory wells drilled into the Longmaxi Formation in South China (Fig. 4),that nearly all wells with yields over 10000 m3/d are located in the Sichuan Basin, wells drilled in the periphery of the Sichuan Basin also provide positive indications, but those drilled far outside of Sichuan Basin were rather poor.Furthermore, if the pressure factor is high, and overpressure is universally present in the drilled formations of the basin with the yield of fractured wells being high; however, if the pressure factor is low, normal or low pressure is universally present in the drilled formation outside the basin, therefore no natural yield forms after fracturing, and the yield breakthrough was impossible without the assistance of artificial clean up processes.

Once again, a number of challenges were encountered in shale-gas exploration of the Cambrian Niutitang Formation and the Sinian Doushantuo Formation in South China. At present, exploration aiming at the shale of the Niutitang Formation received a high yield of shale gas only in the Weiyuan Tectonic Zone of southwest Sichuan, where the Jinye 1HF Well drilled by Sinopec produced a high yield gas flow of 80000 m3/d during the production test. Among the bid-winning shale-gas blocks, only drilling and exploration carried out in Chengkou, Chongqing and Cengong, Guizhou,received better indications, where Tianxing 1 Well yielded 3000 m3/d during the production test after fracturing. Most drillings and explorations aimed at the Niutitang Formation did not achieve good results, due to encountering problems such as low gas content, low methane content, high nitrogen content, and water-bearing formations (Fig. 5). Through analysis, it is believed that complex structure, high thermal evolution and poor preservation conditions are critical factors impacting negatively on shale-gas exploration and development in the Niutitang Formation.

Fig. 4. Distribution map of typical exploratory wells for the Longmaxi Formation in South China.

Fig. 5. Distribution map of typical exploration wells in Niutitang Formation in South China (with supplementary legends).

SCOGR of the CGS innovatively put forward a shale-gas reservoir formation theory based on extrabasinal complex structure regions. Building on in-depth analysis of characteristics in the shale-gas deposition, structure and preservation of the Longmaxi Formation and the Niutitang Formation etc. within and beyond the Sichuan Basin, SCOGR innovatively proposed the shale-gas reservoir formation theories of "Reverse-fault Syncline Reservoir Controlling"and "Paleo-uplift Edge", from which it is concluded that units with a relatively steady structure and better preservation conditions may also exist within residual synclines of extrabasinal complex structure regions; on the edge of Paleouplift, the structure is lifted to a more shallow degree, and the thermal evolution is relatively low, which is beneficial for the preservation of shale gas. Under the direction of these theories, great discoveries of shale gas in the Longmaxi Formation, the Niutitang Formation and the Doushantuo Formation were achieved in Zheng'an, Guizhou, Zhenba,Shaanxi, and Yichang, Hubei, in quick succession. A "fourstory" discovery was made in Anye 1 Well in the Permian Qixia Formation, the Silurian Shiniulan Formation, the Silurian Wufeng-Longmaxi Formation and the Ordovician Baota Formation. The Eyangye 1 Well obtained better oil and gas indications in the Tianheban Formation, the Niutitang Formation, the Dengying Formation and the Doushantuo Formation, drilling 27 strata containing a total of 281 m of gas layers, of which there are 7 strata in Niutitang Formation, i.e.146 m in thickness, and the second section of the Niutitang Formation yielded desorbed gas at a content of up to 2.16 m3/t(excluding gas lost and residual), and generated a high-yield industrial gas flow at 78300 m3/d after the drilling of horizontal wells, fractured in stages and tested for production,resulting in a great breakthrough in capacity for ancient shalegas formations and systems located in an extrabasinal complex structural region. During the drilling of 11 strata of the Doushantuo Formation (118.5 m in thickness), thetotal hydrocarbon content from gas logging was up to 10.42% (at mud density 1.14), the content of on-site desorbed gas was 1.86 m3/t (excluding gas lost and residual), and in the Doushantuo Formation the yield was 5460 m3/d from production tests conducted after the vertical well was drilled and fractured, which is currently the most ancient shale-gas discovery in China. The Zhendi 1 Well drilled through up to 90 m of black quality shale of the Niutitang Formation, with the yielded content of desorbed gas on site being up to 2.92 m3/t, the total gas content up to 6.04 m3/t and the desorbed gas was also successfully ignited.

2.2. Important discovery achieved in shale-gas exploration and the development of transitional facies

In China, the transitional facies shale gas resources are mainly distributed over the Bohai Gulf Basin and the Erdos Basin in North China, the Upper Yangtze region of the Sichuan Basin in South China, and the Tarim and Zhunger-Tuha Basins in Northwest China (Fig. 6). It is a set of strata where the transitional facies shale is symbiotic with the coalstrata shale, mainly consisting of eight sets of shale strata, of which the Shanxi Formation, the Taiyuan Formation and the Benxi Formation, all of which are of the Carboniferous-Permian, are in the Bohai Gulf Basin and the Erdos Basin in North China; the Xujiahe Formation, Liangshan Formation and Longtan Formation, of which all are part of the Triassic-Permian, and are in the Yangtze region; the Badaowan Formation and the Xishanyao Formation of the Triassic-Jurassic are in the Tarim Basin of Northwest China. The marine facies-coal-strata shale is widely developed, at the peak of gas formation, large in total thickness of shale and small in thickness for a single layer, low in the content of brittle minerals, indicating better shale gas resources.

Until now, some great discoveries have been made in North China, Northwest Sichuan and the Lower Yangtze Region. At two bid-winning shale-gas blocks in Wen County and Zhongmou in North China, good shale-gas indications were found by drilling the Carboniferous-Permian transitional facies, with a yield of more than 3000 m3/d through the fracturing of vertical wells, showing promising development.The Gangdi 1 Well deployed in Ningguo, Anhui, made great discoveries in the shale oil and gas of Permian transitionalfacies, encountering more than 70 m thick carbonaceous shale in the Dalong Formation, a content of total hydrocarbon from gas logging ranging from 20%–40%, and methane content of up to 15%. The content of desorbed gas in the shale was 0.5–1 m3/t. The Dongtang 1 Well, drilled in Liuzhou, Guangxi,got a good indication of shale gas in the Lower Carboniferous Luzhai Formation, where a well kick occurred when it was drilled down to 335 m, and the resulting flame was up to 2 meters above the well head. In addition, Sinopec drilled the Xinya HF-2 Well, aiming at the Xujiahe Formation in the northwest of the Sichuan Basin which established a yield up to 46000 m3/d during test production after fracturing. The Yuanye HF-1 Well, drilled in Yuanba of northeastern Sichuan, obtained shale gas of 7000 m3/d after fracturing, and the Jianye HF-1 Well drilled in the Jiannan Block obtained a yield of 12300 m3/d during test production.

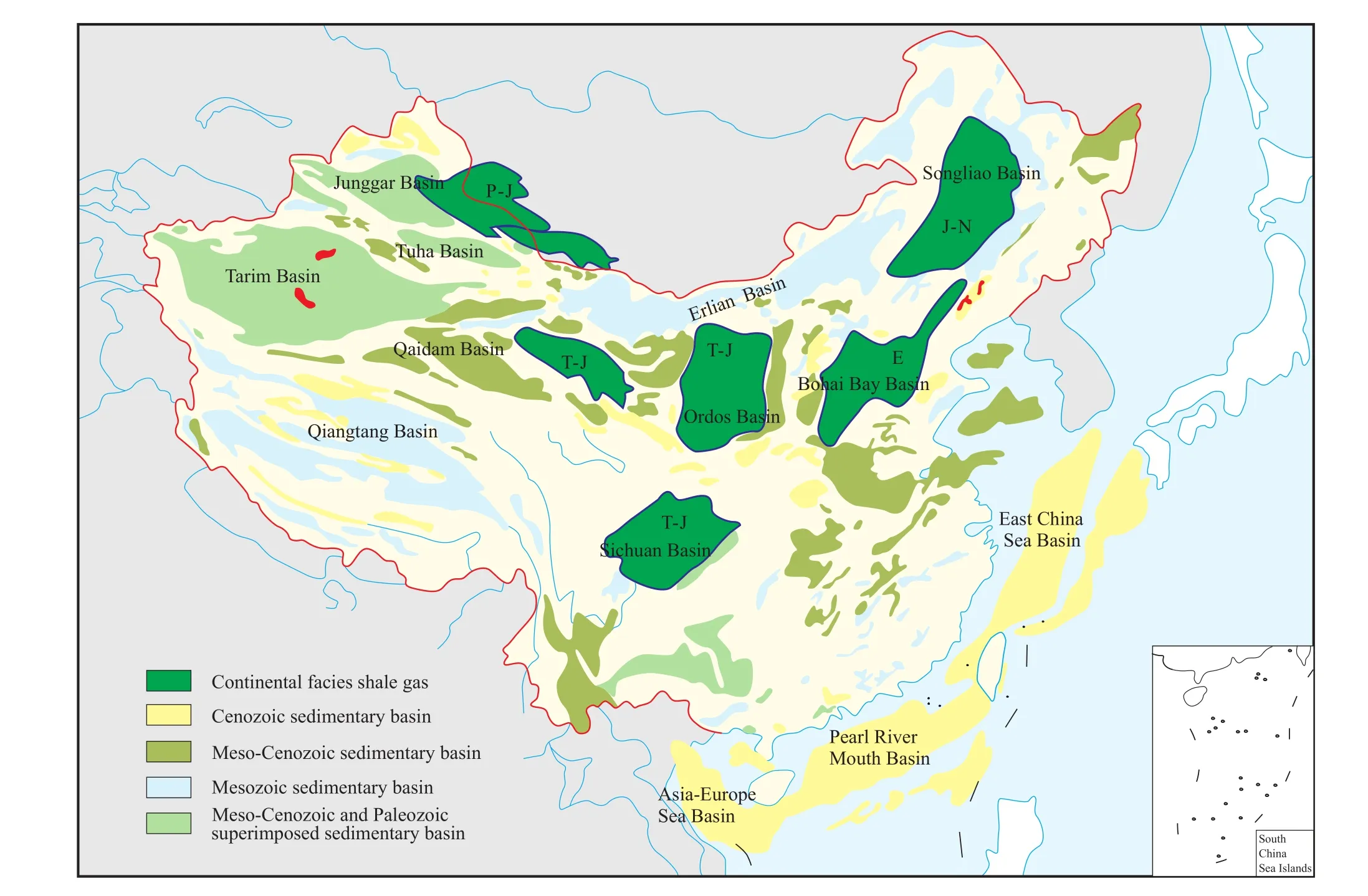

2.3. Better prospects for continental facies shale-gas exploration and development

In China, the continental facies shale-gas resources are mainly distributed over the Songliao Basin, Bohai Gulf Basin and Erdos Basin in North China, and the Sichuan Basin in South China (Fig. 7). It is a set of shale with lacustrine facies deposition, and there are a total of 9 sets of developed shale strata, including the Qing-1 Section and Qing-13 Section in Songliao Basin; the Sha-1 Section, Sha-2 Section and Sha-3 Section in the Bohai Gulf Basin of the Upper Tertiary; the Chang-7 Section and Chang-9 Section of the Triassic in the Erdos Basin; and the Ziliujing Formation and the Xujiahe Formation of the Jurassic in the Sichuan Basin. The lacustrine facies shale is widely developed in these regions, with a large total thickness and a high content of organic carbon, but low evolution as a whole and low content of brittle minerals,signifying a prospecting certainty for shale gas.

Fig. 7. Sketch of the distribution of continental facies organic-rich shale in China.

There exists, however, a better prospect for the development of continental facies shale-gas. Yanchang Petroleum has made breakthroughs in shale-gas exploration in the Erdos Basin, where a few wells, for example, Liuping 177 and Yunye 2, obtained a shale-gas flow that showed good prospects for development. Up to now, 60 shale-gas wells have been completed, of which 50 are vertical wells, 3 are cluster wells and 7 are horizontal wells. The Liuping 177 Well of Yanchang Petroleum drilled into the Ganquan Block achieved a daily yield of up to 2350 m3, and its Yunyaping 1 Well drilled into the Permian Shanxi Formation of the Yishan Slope in the Erdos Basin, after staged fracturing, yielded 20000 m3/d during test production, a great achievement in continental facies shale gas. In recent years, the CGS has deployed multiple shale-oil parameter wells in the Songliao Basin of northeast China, and the Songyeyou 1 Well encountered good shale-oil indications at the Qing-1 Section,yielding 3-5 m3/d of shale-oil through vertical-well fracturing.

3. Initial establishment of shale-gas enrichment and reservoir-formation theories

On the basis of the shale-gas enrichment and reservoir formation of the Wufeng - Longmaxi Formation in Sichuan Basin, a number of experts, who have put forth different theories, such as "Binary Enrichment", "Source-caprock Reservoir Controlling" and "Box-shaped Reservoir Formation",generally hold the belief that the sedimentary facies belt is fundamental, structure preservation is critical and positive structures within the basin aid shale-gas reservoir formation(Guo XS, 2014; Nie HK et al., 2009; Hu DF et al., 2014;Zhang JC et al., 2014; Guo TL et al., 2014; Wang X et al.,2010; Nie HK et al., 2016; Xu ZY et al., 2014). They propose key parameters for the assessment of shale-gas enrichment and reservoir-formation, including the thickness, depth, gasbearing properties, organic carbon content, maturity of the organics, porosity of the organics, brittle minerals and formation pressure factor of quality shale etc. Compared to parameters for shale-gas enrichment and reservoir formation used abroad, the conditions for structural preservation are critical factors to shale-gas enrichment, reservoir formation and high yield in China, while the sedimentary conditions are also emphasized. Building on the progress and investigation into previous theoretical knowledge regarding shale-gas enrichment and reservoir formation, they innovatively propose the triad shale-gas enrichment and reservoir formation theory of "Deepwater Continental shelf facies Shale, Stable Structural Preservation and Formation Overpressure".

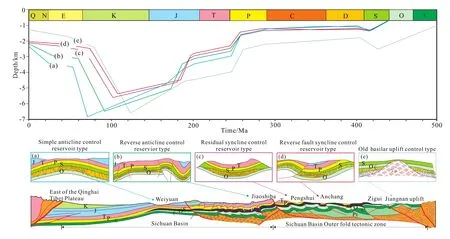

However, if it is believed that in the inner basin shale-gas enrichment and reservoir formation theorises that there are precisely the positive structures beneficial to conditions for shalegas reservoirforming, and it is almost impossible to find any well-preserved shale-gas block outside the basin, does that not mean there is no shale-gas enrichment in any residual syncline outside the basin? In consideration of this question,SCOGR of the CGS has conducted numerous shale-gas basic geological investigations into the extrabasinal complex structure regions in the Wuling Mountain, on the basis of analysis of shalegas enrichment and preservation conditions and drilling results on different types of structures such as the Weiyuan Anticline, the Fuling Reverse-fault Anticline, the Yanggaosi Anticline, the Sangtuoping Residual Syncline, the Wulong and Zhuoheba Shaft-broken Syncline etc., studied the whole process of shale-gas formation, enrichment,convergence and divergence as well as their geological conditions, proposed the converging reservoir formation model with good blocking conditions and the diverging reservoir formation model with relatively open conditions,and concluded that good blocking conditions (a self-closed environment blocked at the top, the bottom and the sides) are critical factors to generating formation overpressure, i.e. the necessary conditions for the structures. Furthermore, SCOGR has classified the anticline, the reverse-fault anticline, the reverse-fault syncline (the first wing of the reverse fault) and the single-wing residual syncline (another wing) etc. into the converging reservoir formation model, and stated that the high points of structures at the shaft of any anticline or close to any reverse fault have high levels of shale gas and oil & gas enrichment (resource density), the higher the structure, the higher its resource density will be; classified the residual syncline, reverse-fault syncline (another wing) and the singlewing residual syncline (the residual wing) into the diverging reservoir formation model, and stated that the shaft of any syncline has higher levels of shale gas and oil and gas enrichment (resource density), the higher the structure, the lower its resource density will be.

First, SCOGR innovatively proposed the "Reverse-fault Syncline Reservoir Control" oil and gas reservoir formation model on complex geological structural regions (Fig. 8), and based on this guidance, comprehensively assessed synclines such as Daozhen, Wulong, Puzi, Tongxi, Gongtan and Anchang, selected and demonstrated the Anchang Reversefault Syncline as their first choice, deployed Anye 1 to drill a well there, and achieved a "four-storey" great discovery in the Permian Qixia Formation, the Silurian Shiniulan Formation,the Silurian Wufeng - Longmaxi Formation and the Ordovician Baota Formation (Fig. 9) in one fell swoop, a steady high-yield industrial flow of 102200 m3/d coming out of the Silurian Shiniulan Formation, making it the first well with a daily yield of over 100000 m3/d in South China outwith Sichuan Basin. SCOGR has opened up new regions, new strata and new types of oil and gas exploration, and created new models and new theories in South China, all of which have played, are and will be playing, an important role of guidance and reference for oil and gas resource exploration in complex structural regions in South China. Furthermore, these demonstrated that the residual syncline in the extrabasinal complex structural regions may possess good conditions for shale gas reservoir formation necessary for structural preservation.

Second, SCOGR constructed the "Paleo-Uplift Edge"shalegas reservoir formation model (Fig. 8). The shale of the Niutitang Formation, though widely distributed in South China and with a large thickness, was found to be poor in gasbearing properties, high in nitrogen content and thermal evolution etc. during drilling, due to the ancient ages of the formations in question, the huge depth and the serious later damage to the structure. Building on the investigations into structures such as the Weiyuan Paleo-uplift in the Sichuan Basin, the Xuefeng Paleo-uplift and the Hannan Paleo-uplift beyond the Sichuan Basin, SCOGR created the "Paleo-uplift Edge" shale-gas reservoir formation model. In this model, it was stated that the Paleo-uplift edge features moderate depth,earlier lifting and weaker structural deformation, and the lower part of the thrust nappe in well-preserved conditions,i.e. the Paleo-shale strata on the edge of the Paleo-uplift and the lower part of the thrust nappe, are still rather low in maturity and better in preservation conditions, therefore beneficial to enrich and preserve shale gas. The base-uplift shale-gas reservoir formation model addresses the problem of high thermal evolution in ancient formations. Based on the concept of "Find Lows Among Highs", great discoveries were made in the Niutitang Formation with the Zhendi 1 Well on the south edge of the Hannan Uplift, in the Doushantuo Formation and the Niutitang Formation with the Zidi 2 Well on the south side of the Huangling Anticline, and in the Niutitang Formation with the Huangdi 1 Well on the west side of Xuefeng Paleo-land, leading to great discoveries and breakthroughs of shale gas in the Niutitang Formation and the Doushantuo Formation. Moreover, the "Four-Storey" great discovery in shale gas and natural gas was also achieved with the Eyangye 1 Well in the Cambrian Tianheban Formation and Niutitang Formation as well as the Sinian Dengying Formation and Doutuoshan Formation.

Fig. 8. Shale-gas reservoir formation model in South China.

Fig. 9. The "Four-Storey" discovery in oil and gas/shale-gas with the Anye 1 Well.

4. Shale gas exploration and development technology gradually maturing in China

With recent years of practice in shale gas exploration and development in China, more and more core and critical technologies have been produced in China, with some technologies taking the lead internationally subsequently being developed to support shale-gas petroleum engineering,contributing to China becoming the third country applying its own independent technologies and capabilities to develop and commercialize shale gas after the US and Canada (Guo XS et al., 2014, Zhu HY et al., 2013; Lu BP, 2013; Wang JL et al.,2012; Guo H et al., 2013; Chen AM et al., 2012; Li X et al.,2013; Hao JF et al., 2012; Yuan GQ et al., 2013; Zeng YC et al., 2013; Shuai Q et al., 2012; Zhang HL et al., 2012; Zhou DH et al., 2014; Wang ZG 2014; Ye DS et al., 2014; Qian B et al., 2015). Innovations, tackling key challenges and field application have led to the provision of equipment for drilling shale-gas horizontal wells and a series of tooling products,developing packaged fracturing equipment and materials,manufacturing well-developed key equipment, tooling and materials for shale-gas exploration and development, and thus substantially reduced the development cost. From introducing and learning of advanced foreign technologies at the beginning, to the establishment of shale-gas exploration and development technology systems with our own intellectual property rights in China through innovation, China has basically experienced the following course for the progress of shale-gas exploration and development technologies (Fig. 10).Currently, China has developed and owns 21 independent proprietary technologies of 5 major technology series - sweetspot identification, reservoir assessment, horizontal welldrilling and completion, shale-reservoir fracturing transformation, and well-factory production model and environmental protection, for example, the seismic/loggingbased reservoir identification and assessment technology,optimization design and geo-steering technology for the drilling of long horizontal wells, the home-made oil-based drilling fluid technology, the combined pumping bridge plug +perforation technology, the fracturing micro-seismic monitoring technology and the like, and exploited their application through the well factory drilling and fracturing model. In shale gas exploration and development, China has put great emphasis on environmental protection. Seeing that South China features karst development on the surface, actions to protect aquifers are taken during drilling by using pneumatic and clean-water drills for the first and second "spud-in".Additionally, the impact on and damage to the local environment are minimized by applying the mud-not-fallingto-ground treatment technology, the oil-based mud harmless treatment technology and the fracturing-flow-back fluid recycling technology etc. during drilling.

Fig. 10. Timeline for the course of progress in shale-gas exploration and development technology in China.

4.1. Initial establishment of geophysical "sweet-spot"identification and reservoir evaluation technology

Currently, the technology systems for South China marine facies shale-gas sweet-spot identification and reservoir evaluation are being developed in the shale-gas exploration blocks where the development is commercialized, including the seismic reservoir identification/evaluation/prediction technology, the logging reservoir identification/evaluation/prediction technology and the logging data quickidentification technology. The marine-facies shale-gas seismic comprehensive evaluation system was established to predict the "sweet-spot" shale strata and sections by combining seismic data and logging.

In the early stages of investigating shale-gas basic geology and evaluating the resource potential, however, the low-cost,green and efficient non-seismic shale-gas exploration technology was developed by using shale-gas non-seismic(gravity, magnetic and electric) techniques and has played an important role in aspects such as the early regional survey,karst detection, research on structural features and prediction of favorable zones, and used to guide subsequent optimal selection of targeted zones and well deployment. "Sweet Spot" prediction technologies, such as the wave-impedance inversion shale-thickness prediction technology, the highprecision pre-stack density inversion TOC technology and the quality shale distribution technology have all been developed on the basis of shale-gas seismic data "Sweet Spot" prediction technology, to guide well deployment and increase the success rate of the shale-gas exploratory wells. With the logging comprehensive evaluation technology, the marine facies shale gas quick-identification model (four highs and three lows) and the models interpreting such key parameters as TOC, porosity and gas content have also been developed.The technical capabilities with which to monitor microseismicity in fracturing wells under different geological and well conditions were created by developing microseismic processing and interpretation systems and detection devices based on the micro-seismic fracturing monitoring technology,so as to give guidance to adjust the fracturing plan in real time.

4.2. Step-by-step establishment of independent horizontal well drilling and the completion technology system

In China, the conventional-orientation-based low-cost well trajectory control technology, the low-cost "MWD +Natural Gama" well trajectory measuring technology, the 3D geological orientation software, the geological orientation technology for remote decision-making, the "logging curve+imaging technology+logging technology+seismic" comprehensive geological orientation technology were all developed. The shalegas horizontal-well optimal-and-quick drilling technology was created and the low-cost oil-based drilling fluid technology was developed. Key drilling speedup tools such as new types of PDC drilling bits and long-life screws were developed, allowing tools to be made in China and allowing drilling speeds at each "spud-in" to continually increase, and the new type of oil-based mud enabled the reduction of the risk of well-bore instability and the cost of the drilling fluid. In China, currently, the "vertical section+the directional section+the horizontal section" three-spud-in drilling spud-in speedup technology was basically developed to drill shale-gas horizontal wells, where the horizontal section is up to 2130 m, the drilling period is at most 37 d and in the horizontal section the length for a single drilling reaches up to 1530 m.

The technologies and equipment supporting the shale-gas drilling and completion are being progressively improved.The shale-gas-specific production casing has been developed to meet the requirements of the alternate load from staged fracturing on the casing tightness; the elastic and tough liquid cement system has been developed so that the toughness of the set cement increases by at least 40%, satisfying the requirement of staged fracturing. In Fuling, Chongqing, the well cementation is 100% qualified, satisfying requirements on operation of staged fracturing in large discharge capacity,so that the shale-gas well cementation technology is domestic,independent and industrialized for its application. The "well factory" efficient drilling operation mode used in complex mountainous ground is formulated and the mobile track rigs are modified so as to move quickly between wells, increase the operational efficiency, cut down the drilling costs and save the land used. Currently, the omni-directional wholetransporting self-moving rig independently and innovatively developed in China, can move a maximal weight of 1000 t, at an inter-well positioning accuracy of less than 10 mm and shorten the time for relocation between wells from the previous 72 h to 4 h.

4.3. Some horizontal-well staged fracturing technologies taking the lead in the world

At present, China possesses and has mastered key technologies for shale-gas horizontal-well staged fracturing and gas production testing, such as the differentiated stagedfracturing process parameter optimization technology, the combined pumping bridge plug + perforation technology, the horizontal-well continual oil-tubing drilling and plugging technology, the efficient fracturing fluid system fit for the shale-gas geological features in China and independently developed-the micro-seismic monitoring technology and postfracturing back-flow processing etc. Supporting equipment,such as the Type 3000 and 4500 fracturing pump trucks which are the first ones in the world, the easy-to-drill composite bridge plug, the soluble bridge plug, the continual oil-tubing operational truck and the high-pressure manifold, have been developed and meet the requirements of shale-gas fracturing operations with high pressure and large power in mountainous areas of China efficiently, effectively and powerfully. The composite fracturing fluid, the propping agent and the fracturing back-flow are recycled and reused, resulting in the development of shale gas on a large scale in China, and some technologies and equipment are internationally advanced and exported in large quantities. Presently, for the horizontal section with lengths ranging between 1000 m–3000 m, the number of fracturing stages for a single well reaches up to 33 and the well-factory fracturing operational mode comes into being. For four wells on the Jianye 42 Platform, 75 stages were fractured in 17 days, total fluid flowing in the well was 133000 m3and total sand flowing in was 4306 m3; the maximal daily number of fractured stages was 8, the daily volume of fluid flowing in the well was 14000 m3and that of the sand was 508 m3, creating a few constructional records in China on a single shale-gas platform, such as the highest number of fracturing stages, the highest volume of sand injected and the largest volume of fluid injected.

Yanchang Petroleum has innovatively experimented to apply the liquid CO2/slick-water mixture fracturing and the pure-liquid CO2accumulatively fracturing 42 well-times. It has tested the water-discharge gas recovery processes, such as the electric submersible pump, the liquid-nitrogen gas lifting,the membrane nitrogen lifting, in normal-pressure regions,and has gradually developed a set of normal-pressurereservoir shale-gas discharge and recovery testing processes.

5. Discussion

5.1. Prospects for shale-gas exploration in China becoming clear

Shale-gas exploration and development in China, though still in its initial stage, has a promising future. Though great breakthroughs are being made in some strata and systems of some regions at present and the potential and prospect of continental and transitional facies exploration and development is as yet unclear, it is expected that there will be future breakthroughs because great discoveries have been obtained in more strata and systems of more regions through survey and evaluation of shale-gas resources.

On the basis of the results from the previous first round of evaluation of national shalegas resource potential, 81 favorable regions were further selected to evaluate the shale gas resource potential of three sets of strata and systems the Sinian System, Cambrian System and Silurian System in South China. Amongst these, for the Sinian shale gas in the Doushantuo Formation, the geological resource and the mineable resource are 6.14×1012m3and 0.79×1012m3in the prospective regions, and 3.45×1012m3and 0.52×1012m3in the favorable regions; for the Cambrian shale gas in the Niutitang Formation, the geological resource and the mineable resource are 16.66×1012m3and 2.65×1012m3in the prospective regions, and 14.35×1012m3and 2.42×1012m3in the favorable regions; for Silurian shale gas in the Longmaxi Formation, the geological resource and the mineable resource are 29.22×1012m3and 5.18×1012m3in the prospective regions, and 27.81×1012m3and 5.11×1012m3in the favorable regions.

According to the present knowledge derived from exploration, it has been concluded that the Lower Silurian Longmaxi Formation within, and in the periphery of, the Sichuan Basin is currently the best one for shale gas exploration and development. The shale gas of the Longmaxi Formation is widely distributed with a large thickness, good gas-bearing potential, and great resource potential, accounting for 20% of national total shale gas resources, thus is extremely promising in terms of exploration and development. The key for future breakthroughs, however, is to discover targeted regions with optimal preservation conditions and develop the fracturing transformation and gas testing processes and technology aimed at normal-pressurelow-pressure shale gas reservoirs. For the Lower Cambrian shale gas in the Niutitang Formation, which is widely distributed throughout South China, large in thickness, high in maturity and scores well for gas-bearing, but is high in thermal evolution, and large in damage to structures and very difficult for exploration, the current preliminary exploration concept is "Find the Lows Among the Highs" and "Find the Weak Among the Strong", based on which some good results have been achieved, and it is required to expand the region and scope of the exploration in the near future in order to make breakthroughs in the capacity. The Upper Paleozoic marine facies in Yunnan, Guangxi and Guizhou, which have good conditions for shale gas formation, are expected to be the next area where breakthroughs in shale gas will be made.Additionally, "three gases" in Permian-coal-bearing strata have showed great developmental prospects.

On the basis of the results from the current survey and evaluation of the shale-gas resources in China, it is predicted that the following five aspects appear likely to bring about new breakthroughs in the future (Fig. 11). (1) By centering on the breakthrough points in regions, such as Jiaoshiba,Chongqing, Changning - Weiyuan, Sichuan, and Zhaotong, Yunnan, and expanding the scope of development through a rolling program of exploration, it seems likely that breakthroughs will be made in the high and steep tectonic zone of the southeast of Sichuan, the south of Sichuan - the north of Yunnan, and the southeast of Sichuan etc. (2)Focusing on the complex tectonic zone of the Wuling Mountain outside the Sichuan Basin, and such complex tectonic regions as the north of Sichuan-the tough Shaanxi, and the north of Guizhou-the south of Guizhou, and by seeking relatively stable tectonic blocks within any residual syncline,favorable target zones like the Anchang Syncline may be discovered. In accordance with the exploration concepts of"Find the Lows Among the Highs" and "Find the Weak Among the Strong" and under the guidance of the "Paleouplift Edge" reservoir controlling theory, it seems likely that breakthroughs will be made in shale gas exploration at the edge of the Hannan Paleo-land, the Huangling Anticline and the Paleo-land of the south of Guizhou. (3) The Permian shale in the middle and lower Yangtze regions, surrounding regions like Ningguo, Anhui, has good prospects for oil & gas exploration. (4) There is great prospects for exploring continental facies shale gas in the north Erdos, Carboniferous-Permian transitional facies shale gas in North China, and three Carboniferous transitional facies gases in the northwest of Guizhou. (5) The continental facies shale in the Songliao Basin of Northeast China, the Zhunger Basin of Northwest China, Qaidam and its surrounding area have all shown great prospects for shale oil & gas exploration.

Fig. 11. Potential prospecting areas of shale gas exploration in China.

5.2. Exploration and development theory and technology still needs to be improved

(1) The enrichment mechanisms for different types of shale-gas need to be better understood. The marine facies shale-gas occurrence mechanisms and enrichment rules in high-evolution and complex tectonic regions are still unclear.The transitional facies on three gases’ concurrent mechanisms and enrichment rules have not yet been formulated. There are various types of low-evolution continental facies shale-gas basins, which vary greatly in thermal evolution, complex in oil and gas occurrence facies, and in the major controlling factors, and the lacustrine facies low-evolution oil and gas coexistence mechanism and the limnetic facies three gases coexistence mechanism are all unclear.

(2) It is urgently required that the shale-gas resource evaluation method and the parameter system be built. Because the basis for the previous evaluation of shale gas resource potential is poor and the error in results from estimation of resources is large, it is urgent to build a method system and parameter system so as to evaluate different types of shale gas resources on the basis of differences in geology and topography.

(3) Tackling key problems in order to work out key technologies for shale-gas exploration and development is still required, and to tackle key problems and do tests in order to develop drilling and completion technologies as well as downhole tools and equipment for horizontal wells in the depths below 3500 m. Moreover, horizontal-well orientation equipment and technologies, and key equipment such as drill bits and bridge plugs, need to be further improved for their quality and technical levels. Developing drilling tools,including more efficient PDC drill bits and oil-resistant screws etc. are also required, to speed up drilling, the pollution-free water-based mud and post-fracturing backflow-fluid treatment technologies must be further researched and developed to abate pollution to drilled formations and the environment by post-fracturing back-flow fluids. Addressing the present challenges in the normal/low-pressure shale-gas reservoir fracturing and back-flow gas testing techniques is also required.

6. Conclusions

(1) China has a tremendous quantity of shale-gas resources, which are of various types and have wide distributions. Compared to the USA, where the geological conditions are relatively uniform for marine facies shale, there are a number of unfavorable factors for shale-gas resources in China, e.g. great depth, complex structure and damaged preservation conditions. Therefore, when evaluating the mineable potential of shale gas, in addition to referencing the parameters used to evaluate shale gas resources in the US, full consideration must be given to the impact of the shale-gas preservation conditions.

(2) The currently developed shale-gas reservoir-forming and enrichment theories, e.g. "Binary Enrichment", "Boxshaped Reservoir Forming", "Reverse-fault Syncline Reservoir Controlling" and "Paleo-uplift Edge Reservoir Controlling" are mere models applicable to individual regions,strata/formations and types, and therefore cannot be promoted and applied universally. Furthermore, due to the shale-gas geological conditions varying greatly across most regions of China, and there being different reservoir-forming and enrichment mechanisms for different types of shale gases,theoretical researches and the development of technologies shall target shale gases of different types in different regions.

(3) Key technologies, for example, shale-gas horizontalwell drilling and staged fracturing and gas testing, are critical to the high yield of shale gas. The sweet-spot technical identification will be the foundation of the high yield of shale gas in the future, and the horizontal-well orientation control technology is critical for determining whether the wells will travel through the quality sections, while staged fracturing and gas testing is the final step, and the fracturing transformation process will decide the effect of that fracturing. Currently,considering shale gas, for which the geological conditions are very complex in China, it is extremely urgent that key problems in the development of these key technologies be tackled, in order to increase shale-gas production capacity.

(4) In China, shale-gas exploration and development is just in its initial stage. Though some breakthroughs and discoveries have been achieved in a few regions, they are just individual breakthroughs in some small areas, and there are a lot of problems still to be addressed. There is a long road still to travel in order to realize the objectives of the production capacity specified in the 13thFive-year Plan of China, due to all the problems that will have to be faced in the future.

Acknowledgments

This article is supported by National Science and technology major projects of "Shale gas resource evaluation method and exploration technology research" (2016ZX-05034), projects of Ministry of land and resources "Basic geological survey project for shale gas in southern China"(121201229000160021) and "Strategic investigation of Zigui-Changyang shale gas favorable area in Hubei" (DD2017-9623), and Sino US intergovernmental cooperation projects of"Sino US collaborative research project on Carboniferous Permian shale reservoir evaluation technology" (2017YFE-0106300).

- China Geology的其它文章

- Deep Continental Scientific Drilling Engineering Project in Songliao Basin: progress in Earth Science research

- Main technical innovations of Songke Well No.2 Drilling Project

- Preliminary results of environmental monitoring of the natural gas hydrate production test in the South China Sea

- Episodic crustal growth in the Tanzania Craton: evidence from Nd isotope compositions

- Origin of natural sulfur-metal chimney in the Tangyin hydrothermal field, Okinawa Trough: constraints from rare earth element and sulfur isotopic compositions

- Overview on hydrothermal and hot dry rock researches in China