Modification of RDX and HMX crystals in procedure of solvent/anti-solvent by statistical methods of Taguchi analysis design and MLR technique

Hamid Reza Pouretedal,Sajjad Damiri,Abolfazl Shahsavan

Faculty of Applied Chemistry,Malek-ashtar University of Technology(MUT),Shahin-Shahr,Islamic Republic of Iran

1.Introduction

The thermal decomposition,sensitivity and operational performance include detonation velocity and shock sensitivity of energetic materials like as RDX and HMX are dependent on the particles size and crystal structure of them[1,2].Therefore,control of preparation conditions of these materials is very important for achieving to desirable properties.The optimization of effective parameters in preparation process can be an importance step for control of particles size and crystal structure of energetic materials.The apparent density is one of the indexes of a crystalline material,because,the apparent density is dependent on the internal defects in a crystalline structure[3,4].

Energetic materials,such as RDX(1,3,5-trinitro-1,3,5-triazinane)and HMX(1,3,5,7-tetranitro-1,3,5,7-tetrazocane),are the main charge explosives of warheads and energetic components of composite propellants.They recently occupied a key position in the field of explosives and propellants[1].With respect to importance of RDX and HMX,the several researches were made on the preparation conditions of these materials.

The solubility of HMX in acetone was measured by Cao et al.[5].Intermittent dynamic method was utilized to study crystallization kinetics of HMX in acetone.They found that the crystal apparent density of HMX is in the range of 1.8993 g˙cm-3 to 1.9017 g˙cm-3,very close to the theory density of HMX;the internal defects and the crystal size do not increase after 25°C.These results suggest that the nucleation rate is a significant factor influencing the crystal internal defects,and larger nucleation kinetics can reduce crystal internal defects[5].

Intragranular defects inside RDX/HMX were studied by Hua et al.[6].The results revealed the phenomenon that RDX/HMX had more defects and cracks than RS-RDX/RS-HMX.An analysis of the relationship between defects inside RDX/HMX crystal and shock sensitivity was made.Finally,the shock pressure response under impact loading was investigated by discrete element method[6].

The synthesis of ultrafine Hexogen(UF-RDX)of size<5μm by drowning-out crystallization was studied by Pantet al.[7].RDX was precipitated from acetone or dimethylformamide(DMF)solution by reducing the solvent power using a miscible,non-aqueous antisolvent,n-hexane,or an aqueous anti-solvent,water containing polyethylene glycol(PEG).Process parameters such as solvent/antisolvent ratio,agitation,ultrasonication etc.were studied.

The crystallization of HMX in acetone was investigated by Basu and co-workers[8].A ternary system consisting of HMX,acetone and water was studied in order to obtain solubility data and influence of different parameters viz percentage recovery of solvent,stirrer speed,cooling rate and rate of recovery of solvent on the size distribution of HMX.

The HMX was recrystallized from different solvents by a cooling crystallization process to improve the product quality and to produce a more insensitive product[9].It was found that particles with the best quality were crystallized from propylenecarbonate with a nucleation initiation by dosing a small amount of water as drowning-out substance.This leads to particles with a very high density(near to the theoretical value)and thus to particles with a small amount of inclusions.

The major of researches on the quality of HMX and/or RDX are crystallization of these materials by solvent/anti-solvent process in order to minimization of internal defects.For achieve to this aim,the optimization of process is an important step.Thus,the aim of this work is optimization of solvent/anti-solvent process by using the statistical methods such as Taguchi analysis design.For control of internal defects of crystals,the apparent density is used as an output signal.Also,the multiple linear regression(MLR)was used for obtain a model of prediction of apparent density from optimized parameters.

The Taguchi method uses a special design of orthogonal arrays to study the entire parameter space with only a small number of experiments[10].Taguchi methods[11]have been widely utilized in engineering analysis and consist of a plan of experiments with the objective of acquiring data in a controlled way,in order to obtain information about the behavior of a given process.The greatest advantage of this method is the saving of effort in conducting experiments;saving experimental time,reducing the cost,and discovering significant factors quickly[12,13].

2.Experimental

The recrystallization of HMX and RDX(purity of>99%)was made by solvent/anti-solvent method using acetone(>99%,AR)as solvent and deionized water as anti-solvent.The experimental design for control of apparent density of HMX and RDX crystals was made with optimization of parameters including ratio of anti solvent to solvent(V/V),ratio of solute to solvent(g/mL),aging time(h)and cooling rate(oC/min)of mixture of anti-solvent/solvent.

A 1 L jacketed dissolution vessel with a controlled temperature(±0.1°C)was used to conduct the crystallization experiments.A certain amount of HMX and/or RDX(0.05-0.4 g/mL)was dissolved in hot acetone(the initial temperature was near to boiling point of acetone).The weight of HMX and/or RDX was determined using an analytical balance(±0.0001 g).The obtained solution was stirred by a mechanical stirrer.After complete dissolution of solute(10-15 min),the anti-solvent was added by a burette slowly in ratios of 3:1 to 1:1 of anti-solvent to solvent.After,the complete addition of anti-solvent,the mixture was aged(0.5-2.0 h).Then,the temperature of vessel was decreased to temperature of 20°C in a selected cooling rate(2.0-0.5°C/min.).When a large number of crystals were formed,the HMX and/or RDX suspension taken from the crystallizer was filtered over a bush funnel equipped with an aspirator.The filtered HMX and/or RDX crystals were dried in a vacuum oven until keeping balance weight.

Apparent densities of HMX and RDX crystals were measured by sink-float method.The obtained crystals were floated in a mixture of dibromomethane in methanol solvent.The images of optical microscopy with matching refractive index were obtained by Nikon Instrument light microscope system.Also,a Philips XL30 scanning electron microscope was used to obtain the SEM images.

3.Results and discussion

3.1.Taguchi design and S/N ratio

Taguchi methods which combine the experiment design theory and the quality loss function concept have been used in developing robust designs of products and processes and in solving some taxing problems of manufacturing[12,13].

The four parameters(Table 1)including the volume ratio of antisolvent to solvent(X1),ratio of dissolved amounts of solute(RDX and/or HMX)to volume of solvent(X2),aging time(h)of mixture(X3)and cooling rate(oC/min)of mixture of anti-solvent/solvent(X4),were used for optimization of anti-solvent/solvent procedure in recrystallization of HMX and/or RDX particles.The apparent density(A.D)of the obtained crystals as a represent of internal defects of crystals was followed in optimization process.Each parameter was used in four levels with the degrees of freedom(DOF)of 4-1=3[13].

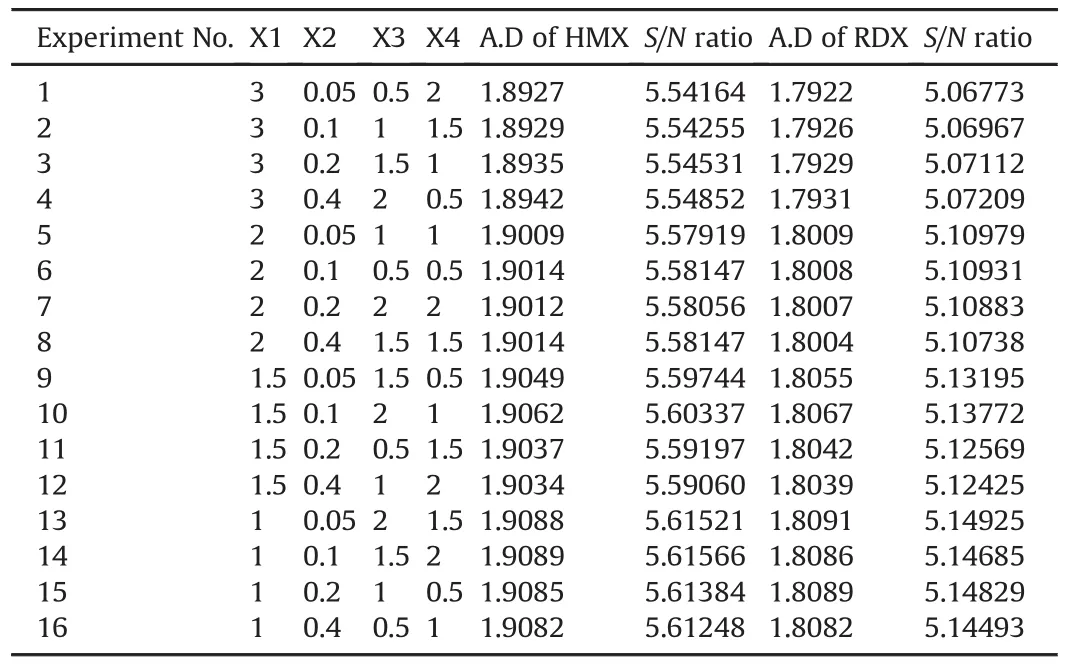

In this research,16 experiments were conducted at different conditions of used parameters(Table 2).The Taguchi L16 orthogonal array was used,which has sixteen rows corresponding to the number of tests,with four columns at four levels.L16 OA has 12 DOF for four factors(each one 3 DOF)and 4 DOF was assigned to the error.Thus,for the purpose of observing the degree of influence of the selected parameters on the apparent density,four factors,each at four levels,are taken into account,as shown in Table 2.The apparent density values(the mean of three times measurements)and ratio of signal to noise(S/N)corresponding to each experiment were also shown in Table 2.

In this study,the S/N ratio was chosen based on larger-the better,in order to maximize the response(apparent density)determined by equation(1)

Where ‘n’is the repetitions in each trial(n=3)and ‘Y’is the experimental apparent density.The higher S/N value of the response denotes the optimum parameters.

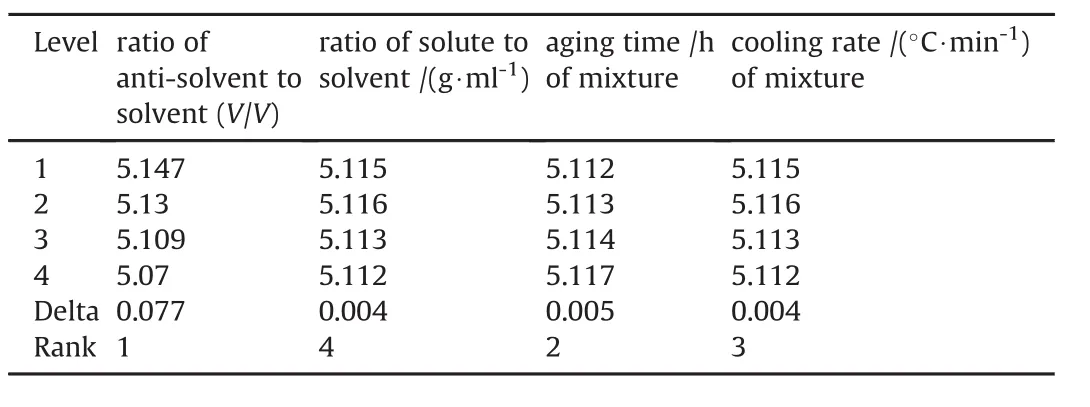

The values of signal-to-noise(S/N)ratio of apparent densities of re-crystals of HMX and RDX microparticles in Taguchi analysis by factor level are collected in Tables 3 and 4,respectively.The apparent density was considered as the quality characteristic withthe concept of “the larger-the-better”[14].Also,the main effects plots for S/N ratios of Taguchi analysis were indicated in Figs.1 and 2,respectively,for recrystallization of RDX and HMX particles.As seen from Table 3,the highest S/N ratio values for apparent densities of RDX crystals are obtained 5.147,5.116,5.117,and 5.116,respectively,for ratio 1:1 anti-solvent to solvent,0.1 g/mL solute to solvent,aging time of 2 h and cooling rate of 1°C/min(See Table 1).As similar to the obtained results for recrystallization of RDX,these levels of studied parameters were optimized for recrystallization of HMX particles with S/N ratios of 5.614,5.586,5.587 and 5.585,respectively(Table 4).Also,the obtained graphs in Figs.1 and 2 showed that the optimized parameters in recrystallization process were:ratio of anti-solvent to solvent of 1:1,ratio of solute to solvent of 0.1 g/mL,aging time of 2 h and cooling rate of 1°C/min.Thus,the re-crystals of HMX and RDX with minimum internal defects are obtained in optimized conditions.

Table 1Solvent/anti-solvent process parameters for crystallization of HMX and/or RDX.

Table 2Taguchi L16 OA for apparent density(A.D,g/cm3)of HMX and/or RDX crystals.

Table 3The S/N ratio values for optimization of recrystallization process of RDX particles by factor level in Taguchi analysis.

Table 4The S/N ratio values for optimization of recrystallization process of HMX particles by factor level in Taguchi analysis.

3.2.MLR model

The correlation between parameters and apparent density of recrystals of HMX and/or RDX were also obtained by multiple linear regressions(MLR)technique.The standard commercial statistical software package MINITAB was used to derive the models.The regression coefficients,coefficients of parameters and ANOVA data for re-crystallization process of HMX and RDX are given in Tables 5 and 6,respectively.The regression coefficients in Tables 5 and 6 tell how strong the linear relationship is between the independent variable(studied parameters)and dependent variable(apparent density).The R square value(R2)is the coefficient of determination that means how many points fall on the regression line.These coefficients(R2>0.90)indicate that the fit of the experimental data is satisfactory for the proposed models.In ANOVA(analysis of variance),the SS is sum of squares,regression MS is regression SS/regression degrees of freedom,residual MS is mean squared error(Residual SS/Residual degrees of freedom),F is overall F test for the null hypothesis and significance F is the significance associated P-value[15].

The obtained results of MLR technique show that the sign of coefficients of X1,X2 and X4 are negative and inversely,the sign of coefficient of X3 is positive.In the other words,the increasing of ratio of anti-solvent to solvent,the initial amount of solute and the rate of cooling rate of mixture is due to decreasing of apparent density.Decreasing of apparent density can be related to increasing of internal defects of re-crystals[1,16].But,the re-crystals of HMX and RDX with less internal defects can be obtained with increasing of aging time of mixture.Because,the increasing of aging time is due to increasing of apparent density of HMX and RDX re-crystals.

The P-value of all parameters or predictor's(independent variables)in optimization of recrystallization process of RDX and HMX are<0.05 except the P-value of coefficient of X2 in Table 5.A low p-value(<0.05)indicates that the null hypothesis is rejected.In other words,a parameter that has a low p-value is likely to be a meaningful addition to your model because changes in the predictor's value are related to changes in the response variable[17].Conversely,a larger(insignificant)p-value suggests that changes in the predictor are not associated with changes in the response.Thus,in confidence level of 95%,the null hypothesis is rejected and a meaningful addition is observed in the model because changes in the predictor's value are related to changes in the response variable of apparent density.

Table 5The results of MLR include regression coefficient,ANOVA data and statistical coefficients of parameters for prediction model of apparent density in crystallization process of HMX.

Table 6The results of MLR include regression coefficient,ANOVA data and statistical coefficients of parameters for prediction model of apparent density in crystallization process of RDX.

3.3.Images of recrystallized particles

As mentioned,the apparent density of re-crystal particles was used as a characterization for evaluation of internal defects.Thus,the images of optical microscope were applied for this relation.The images of optical microscope of micro-particles of HMX crystals are shown in Fig.3.Fig.3a shows the micro-particles of HMX with the minimum internal defects.The recrystallization conditions are related to the experiment No.14 of Table 2.The apparent density of re-crystal particles is 1.9089 g/cm3.The absence of internal defects can be seen from image of Fig.3a.The image of re-crystals of the obtained HMX from experiment No.4(Table 2)is shown in Fig.3b.The re-crystal particles of HMX indicate the apparent density of 1.8942 g/cm3.The internal defects including a few inclusions in the re-crystal particles are seen in this image[17,18].

As a sample,the SEM images of the obtained HMX re-crystals in the experiment No.14 are shown in Fig.4.These SEM micrographs indicate that the re-crystals have various shapes and sizes[19,20].

4.Conclusion

The formation of particles of explosives such as HMX and RDX in a re-crystallization process can be due to reduction of the number of internal defects.The solvent/anti-solvent method can be used as a familiar,simple,available and safe method for re-crystallization process.The optimization of influenced parameters by using statistical methods is due to the reduction of the number of experiments and save cost and time.Also,the measurement of apparent density of re-crystal particles can be used as a representative of internal defects.

Taguchi analysis is used in optimization of influenced parameters and the obtained results show that in ratio 1:1 of anti-solvent/solvent,0.1 g/mL of solute/solvent,time of 2 h for aging step and 1°C/min for cooling rate,the apparent density of re-crystal particles of HMX and RDX are nearest to theory values.Also,the multiple linear regressions(MLR)indicate that there is meaningful relationship between selected parameters and apparent density of recrystal particles.

[1]Huang B,Cao M,Nie F,Huang H,Hu C.Construction and properties of structure-and size-controlled micro/nano-energetic materials.Def Technol 2013;9:59-79.

[2]Khasainov BA,Ermolaev BS,Presles HN,Vidal P.On the effect of grain size on shock sensitivity of heterogeneous high explosives.Shock Waves 1997;7:89-105.

[3]Zhang YX,Liu DB,Lv CX.Preparation and characterization of reticular nano-HMX.Propell Explos Pyrot 2005;30:438-41.

[4]Prourmortazavi SM,Hajimirsadeghi SS.Application of supercritical carbon dioxide in energetic materials processes:a review.Ind Eng Chem Res 2005;44:6523-33.

[5]Cao X,Duan X,Pei C.Study on crystallization kinetics and the crystal internal defects of HMX.Cryst Res Technol 2013;48:29-37.

[6]Hua C,Zhang P-J,Lu X-J,Huang M,Dai B,Fu H.Research on the size of defects inside RDX/HMX crystal and shock sensitivity.Propell Explos Pyrot 2013;38:775-80.

[7]Pant A,Nandi AK,Newale SP,Gajbhiye VP,Prasanth H,Pandey RK.Preparation and characterization of ultrafine RDX.Cent Eur J Energ Mater 2013;10:393-407.

[8]Basu S,Gawande NM,Apte ME,Narasimhan VL.Crystallization of HMX in acetone-water system.Indian J Chem Technol 2004;11:575-81.

[9]Kr?ber H,Teipel U.Crystallization of insensitive HMX.Propell Explos Pyrot 2008;33:33-6.

[10]Wh Y,Ys T.Design optimization of cutting parameters for turning operations based on the Taguchi method.J Mater.Process Technol 1998;84:122-9.

[11]Taguchi G.Introduction to quality engineering.Tokyo:Asian Productivity Organization;1990.

[12]Khosravi-Darani K,Vasheghani-Farahani E,Shojaosadati SA.Application of the Taguchi design for production of Poly(-hydroxybutyrate)by ralstonia eutropha.Iran J Chem Chem Eng 2004;23:131-6.

[13]Taguchi G,Hocheng H.Taguchi methods orthogonal arrays and linear graphs,tools for quality engineering.Dearborn,MI:American Supplier Institute;1987.p.35-8.

[14]Zandevakili S,Ranjbar M,Ehteshamzadeh M.Synthesis of lithium ion sieve nanoparticles and optimizing uptake capacity by Taguchi method.Iran J Chem Chem Eng 2014;33:15-24.

[15]Pouretedal HR,Keshavarz MH,Abbasi A.A new approach for accurate prediction of toxicity of amino compounds.J Iran Chem Soc 2015;12:487-502.

[16]Miller GR,Garroway AN.A review of the crystal structures of common explosives Part I:RDX,HMX,TNT,PETN,and Tetryl.Washington,DC:Naval Research Laboratory;October 15,2001.p.20375-5320.NRL/MR/6120-01-8585.

[17]Herrig IM,B¨oer SI,Brennholt N,Manz W.Development of multiple linear regression models as predictive tools for fecal indicator concentrations in a stretch of the lower Lahn River Germany.Water Res 2015;85:148-57.

[18]Borne L,Patedoye J-C,Spyckerelle C.Quantitative characterization of internal defects in RDX crystals.Propell Explos Pyrot 1999;24:255-9.

[19]Qiang T,Guanyun Y,Guangai S,Chaoqiang H,Lei X,Hongzhen L,Bo C.Defects characterization of molecular crystal explosives.In:Proceedings of the 2011 international autumn seminar on propellants,explosives and pyrotechnics Nanjing,Jiangsu,China;September 20-23,2011.

[20]Van der Heijden AEDM,Bouma RHB.Crystallization and characterization of RDX,HMX,and CL-20.Cryst Growth Des 2004;4:999-1007.

- Defence Technology的其它文章

- Approximate ballistics formulas for spherical pellets in free flight

- An experimental study on shock wave mitigation capability of polyurea and shear thickening fluid based suspension pads

- Contemplation on some cyclic N8isomers-A DFT treatment

- Cold metal transfer(CMT)technology-An overview

- Numerical and experimental study of wave shaper effects on detonation wave front

- Microstructure,properties and hot workability of M300 grade maraging steel