Sensory Evaluation of Hydroxy Ethyl Cellulose (HEC) in Facial Mask

Li Yanan, Zhao Xiaomin, Qu Xin

Ashland Specialty Ingredients, Shanghai Technical Center, China

In recent years, the facial mask market has been one of the most rapidly developing cosmetic segments.According to Mintel’s survey report,[1]in 2016, facial mask was the second most frequently used skin care product for Chinese consumers (the most frequent was facial cleansing products), among which, sheet facial masks were the most popular item. In sheet facial mask products, the mask fabric and serum are not able to be separated. For optimum results, special attention must be paid to the compatibility of the mask fabric and serum during the product development process. However,recent facial mask research has only focused on either the material of the mask fabric itself[2]or a sensory and efficacy evaluation of the mask.[3,4]There is not much research regarding the compatibility of mask fabric and serum.

Common mask fabrics include tencel, modified tencel, filaments, natural cotton, bamboo charcoal,bamboo fiber, chitosan and blend fibers. Common mask serums include rheological thickeners, moisturizers,active ingredients and preservatives. Hydroxyethyl cellulose (herein after abbreviated as HEC) is a nonionic water soluble high molecular polymer. It is widely used in the cosmetics industry for its excellent electrolyte resistance, biocompatibility and water binding properties.HEC is commonly used as a thickening agent for skeletal components of facial mask serums. It is comfortable when applied to the skin and is also used for lubrication and improving softness and adhesion. Therefore,the appearance of HEC in facial masks has increased significantly in recent years. According to Mintel, the number of new facial masks containing HEC in China rose from 38 in 2014 to 136 in 2015 and again to 176 in 2016. The use of HEC can also be seen in the daily chemical industry, however, currently is only seen in soap based shower gels, creams, toothpastes and shampoos.[5,6]Although HEC is widely used in facial masks, very little relevant research has been published on its application.Our study uses a variety of mask fabrics to explore the skin comfortableness and compatibility of mask serums containing HEC. We also conducted a comparative study of HEC and xanthan gum which included an equipment test and sensory evaluation. The equipment test assessed wetting ability, softness and the tensile impact of HEC to mask fabrics. The sensory evaluation included a facial mask softness test, double-blind split face test and a randomized sensory evaluation. Our aim was to conduct a systemic equipment test and sensory evaluation to provide a reference for future formula development.

Experimental section

Reagents and instruments

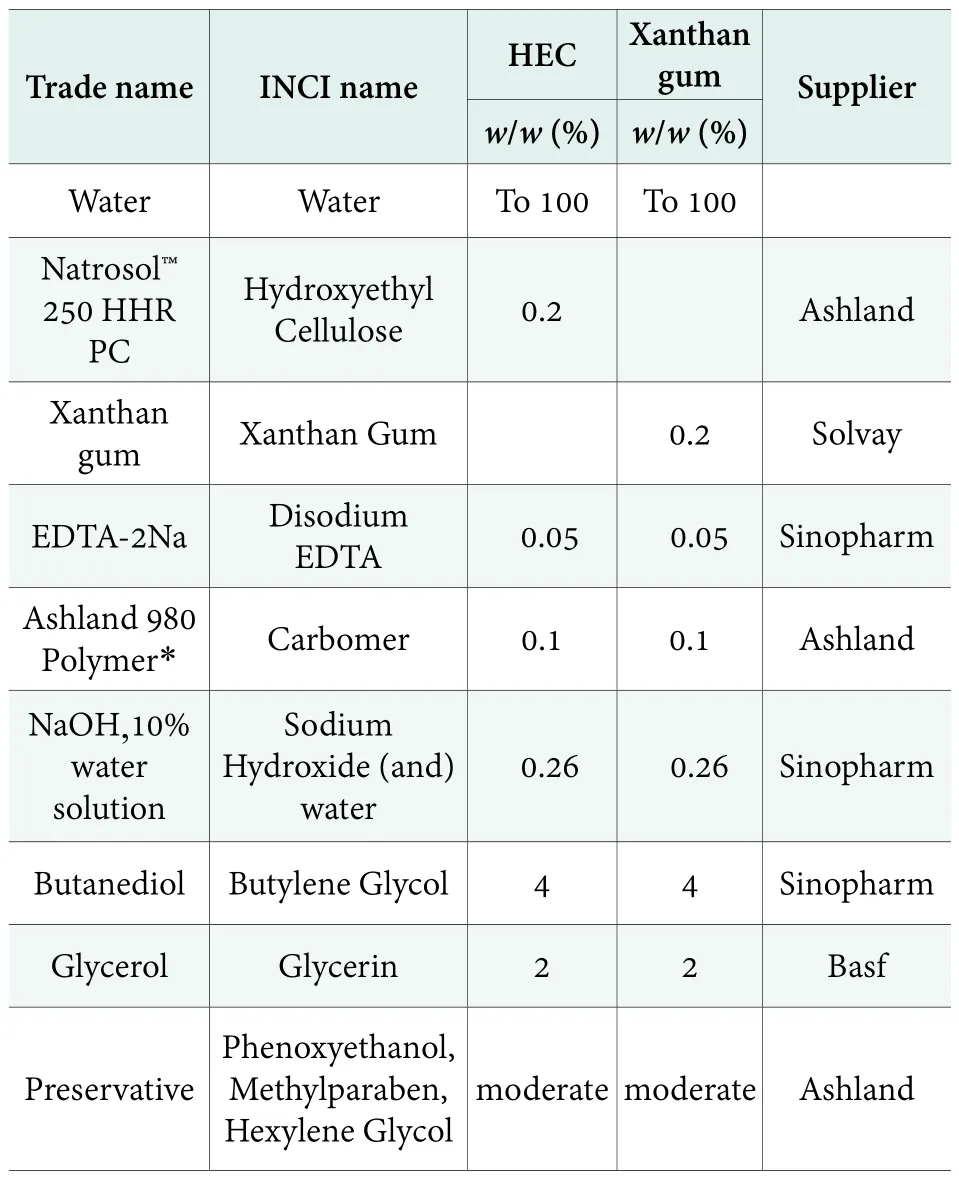

Mask fabrics: 80 g filament, 65 g 2-layer fiber, 60 g filament, 60 g tencel, 50 g bamboo charcoal, 40 g chitosan,38 g filament, 30 g natural cotton, 35 g 3 blend fibers, 35 g baby fiber, 30 g tencel (provided by Cdlunion), 50 g bamboo fiber and 40 g pure cotton (provided by Nox Bellcow). The mask serum formula is shown in Table 1. The instrument used to measure softness of the mask was a texture analyzer TA.XT.Plus, P1S probe, TA. A Leica S8AP0 microscope was utilized to observe the microstructure of the mask fabric.

Table 1. Facial mask serum formula

Experimental method

1) Preparation of the mask

Our mask serum formula was based on the Mintel's commercially available mask serum. After selecting the HEC/xanthan gum and carbomer combination, the dosage of HEC/xanthan gum was applied according to the industry standard. Concurrently, the solutions contribution to viscosity of the mask serum was controlled to remain in a reasonable range. This was done to ensure fluidity of the mask fabric so that it could be easily wet and minimize dripping. The different types of mask fabrics were folded in a uniform manner and then placed in a mask bag filled with 25 g of mask serum (one piece)or 15 g of mask serum (half piece). Next, they were gently pressed and sealed to ensure the mask fabric was completely wet. Testing took place after a week or 20 days of wetting.

2) Mask fabric wettability and tensile capacity test

A total of 11 mask fabrics were evaluated. After removing the mask from the bag and hanging it, the effect of the mask serum on the wettability and tensile capacity of the mask fabric was photographed.

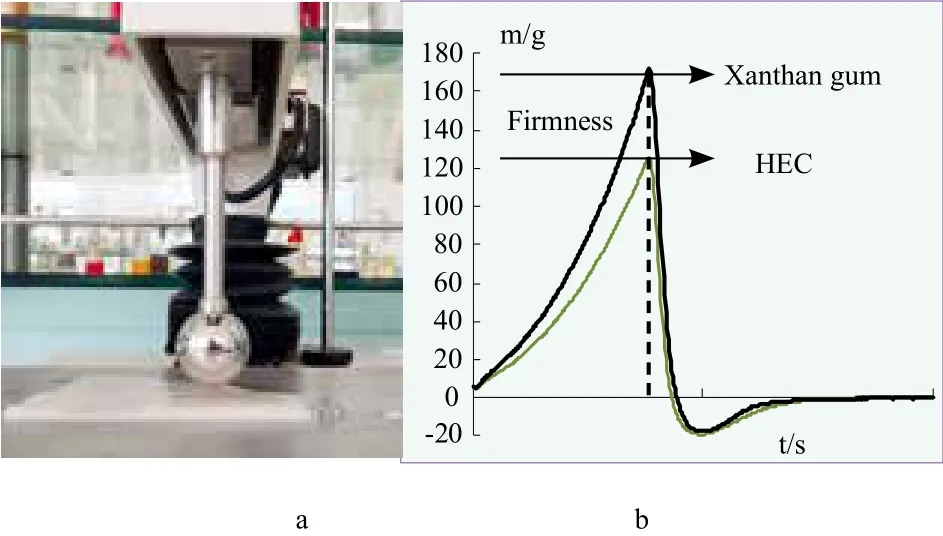

3) Mask fabric softness test

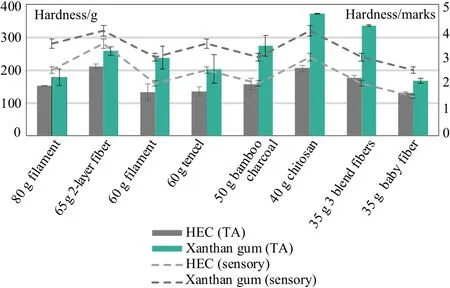

A total of 8 mask fabrics were evaluated. The instrument tests were conducted using a texture analyzer.After the mask was removed, it was placed under a P1S probe (see Figure 1a). The probe pressed against the mask fabric and traveled 1.5 mm. The maximum force measured was used to characterize the mask fabrics softness (see Figure 1b). A smaller maximum force demonstrates a softer mask fabric. Each mask fabric was tested twice and an average of the two maximum forces was taken to be the mask’s hardness value. The sensory evaluation involved two expert assessors touching the mask by hand and giving a score ranging from 0 to 5 regarding the hardness of the mask. A higher hardness score represents a harder mask.

Figure 1. Texture analyzer (P1S probe) to detect the softness of facial mask

4) Mask split face test

A total of 6 pairs of mask fabrics were evaluated using a double-blind and randomized control method test.10 trained expert assessors applied the mask using the standard procedure and evaluated the skin feel during and after application. The application time was 20 minutes.If there was residual serum on the face after removal of the mask it was gently massaged into the skin without cleaning. The scoring system ranged from 0 to 100 points.The average value of all expert assessors was taken to be the final score. The results were statistically analyzed using a two-tailed T test.

Results and discussion

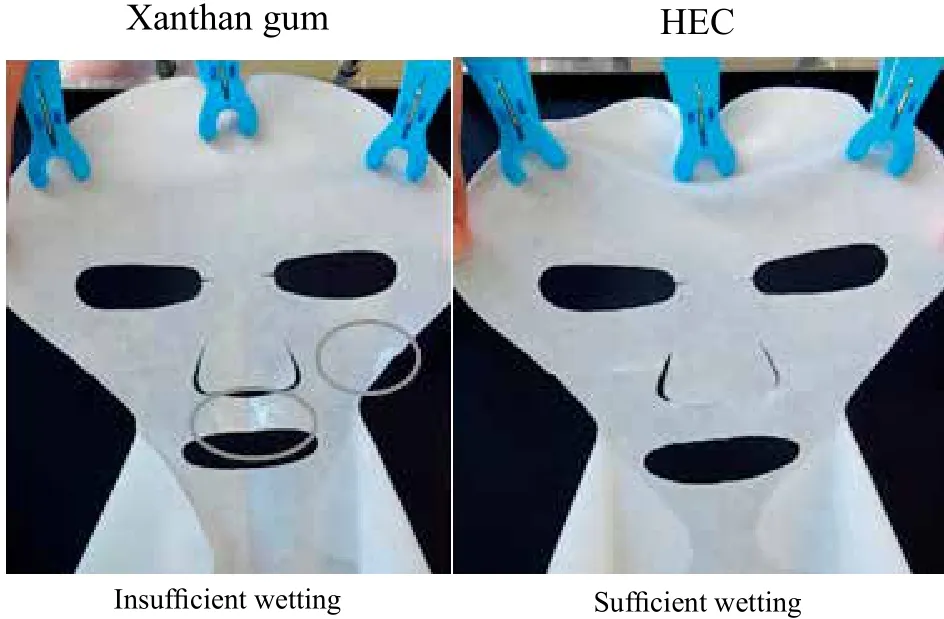

Mask wettability

Mask wettability refers to the ability of the mask serum to wet the mask fabric evenly and completely. The wetting experiment results of the 11 mask fabrics showed that thin and medium thick mask fabrics (regardless if the mask serums contained HEC or xanthan gum) had good wettability. After 20 days of wetting, thick mask fabrics containing xanthan gum such as the 65 g 2 layer fabric and the 80 g filaments were still unable to completely wet the mask fabric evenly (see Figure 2). The performance of HEC was significantly better than that of xanthan gum.

Figure 2. The wetting ability of HEC vs xanthan gum

Mask tensile capacity

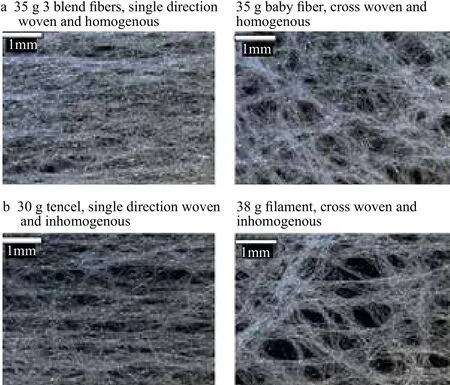

Mask tensile capacity refers to the ability of the mask fabric to stretch when applied to the face. The suspension test results of the 11 mask fabrics showed that in medium thick, thick and cross woven & homogeneous thin mask fabrics (9/11 mask fabrics including 80 g filaments, 65 g 2 layer fabric, 60 g filament, 60 g tencel,50 g bamboo charcoal, 40 g chitosan, 30 g natural cotton,35 g 3 blend fibers and 35 g baby fiber), HEC had proper tensile capacity and could adapt to different face sizes.Photographic evidence from the microscope is shown in Figure 3a. A micrograph of single direction woven or inhomogeneous thin mask fabrics (2/11 mask fabrics including 30 g tencel and 38 g filaments) is shown in Figure 3b. The results display that HEC causes excessive stretching and deformation. It is also worthy to note that composite fibers containing tencel or filament fiber can improve the structural strength of mask fabrics. This was seen in the composite fiber mask fabrics: 35 g 3 blend and 35 g baby fibers. Even though they are thin mask fabrics,they displayed good structural strength and mask serum which contained HEC did not cause them to stretch excessively.

Figure 3. Microscope pictures of different mask fabrics

Mask softness

Mask softness can be evaluated through a newly developed quantitative testing method which uses a texture analyzer and P1S probe (see Figure 1a). Texture analyzers are widely used in the cosmetics and food industries as they can quantitatively test the sensory characteristic of products.[7,8]Utilizing the compression test mode, the P1S probe presses the folded mask fabric over a short distance. The maximum force measured during this process can then be used to determine the softness of the mask. A smaller maximum force represents a softer mask (see Figure 1b). This method simulates the process of pressing the mask with a finger as the tip of the P1S probe is hemispherical just like a finger. The hardness value results of the mask measured via this method (bar graph in Figure 4) were in agreement with the sensory evaluation results conducted by the panelists (line graph in Figure 4). The equipment test and sensory evaluation results (see Figure 4) regarding the softness of the eight mask fabrics wet with a mask serum containing HEC or xanthan gum demonstrated that HEC was more effective in softening mask fabric compared to xanthan gum.Therefore, it was speculated that HEC may also be more adhesive to the skin.

Figure 4. Softness test results of the 8 mask fabrics(TA & sensory tests)

Mask split face test – a sensory evaluation

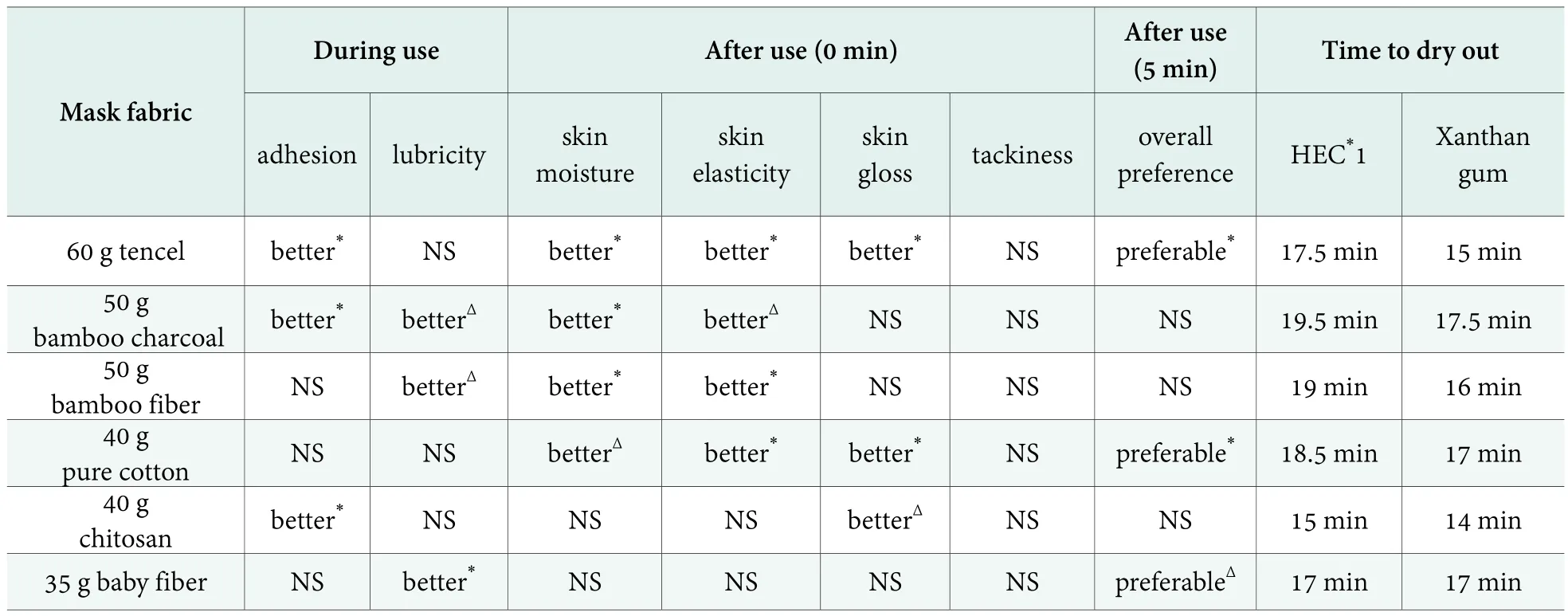

Six facial mask fabrics which had different thicknesses and which were constructed from different materials were selected at random and evaluated by 10 expert assessors using a split-face test. The evaluation phases were during use, after use 0 min and after use 5 mins. The results of the sensory evaluation are shown in Table 2. The results displayed that mask containing HEC had better adhesion and lubrication during and after use, left the skin moister,had improved elasticity and gloss and had a longer dry out time than masks containing xanthan gum. HEC and xanthan gum displayed a very similar result on the 35 g baby fiber. However, for the remaining five mask fabrics,HEC was able to prolong the mask dry out time by 1~3 mins longer than the xanthan gum counterpart. Mask dry out time refers to the time taken for evaluation staff to begin to feel the mask drying out. Drying out specifically refers to areas in the mask which begin to feel tight or detachment becomes visible. Overall, the expert assessment team preferred the skin feel of HEC mask fabrics.

Discussion

The instrument test results showed that HEC has a stronger ability to wet mask fabric, soften mask fabric and impart tensile capacity than xanthan gum. The results of the equipment test indicated that HEC is better able to fit different face shapes and has a stronger adhesion ability.The results of the split-face sensory test also confirmed these results. During the application process, HEC mask fabrics had a better fit and adhesion to the skin than xanthan gum fabrics. More bubbles and detaching in certain stereoscopic parts of the face especially around the corners of the nose and eyes were seen in xanthan gum fabrics. A factor causing this may be due to the fact that HEC is a cellulosic product and has a similar structure to the material of the mask fabric itself. HEC also has a large hydroxyl exposure which can form a higher density hydrogen bond with the mask fabric, allowing the mask fabric to absorb more moisture and improve tensile capacity. Furthermore, a higher density hydroxyl group can convert more free water into bound water. This meansthere is a stronger water binding and water retaining capacity, resulting in prolonged dry out times. Xanthan gum on the other hand is made mostly of intra-molecular hydroxyl. The density of hydrogen bonds and the water binding capacity is low, therefore, it is more difficult to become moist, adhesion to the skin is relatively poor and the dry out time is shorter. The purpose of a facial mask is to achieve deep skin repair and nourishment by increasing skin temperature, opening pores via local encapsulation,promoting sweat gland secretion and metabolism,increasing oxygen content of the skin and increasing serum absorption.[9]HEC is a structural component of the mask serum and compliments the functions of a mask.On one side, HEC improves binding and tensile capacity of mask fabric to help ensure that the mask has a certain amount of stretch when used by consumers with different face types. On the other side, HEC improves binding in the moisture of the serum meaning prolonged mask dry out times. This combination of effects leads to optimal mask functioning.

Table 2. The sensory characteristics of HEC in comparison to xanthan gum and the respective dry out times for HEC and xanthan gum

Conclusion

The equipment test and sensory evaluation was conducted to compare the compatibility and sensory characteristics of HEC and xanthan gum in facial masks.The equipment test results confirmed that in strong structured mask fabrics such as medium thick, thick and cross woven & homogenous thin mask fabrics, HEC improved tensile capacity. Mask serum containing HEC also displayed an improved wettability and mask fabric softness than xanthan gum masks. This gives masks more adhesion and flexibility for different face shapes. HEC can also bind moisture molecules more effectively than xanthan gum resulting in a more moisturizing mask and overall creating a more effective facial mask. The split face sensory evaluation results demonstrated that the sheet masks containing HEC had better adhesion and lubricity,provided the skin more moisture, had improved elasticity and gloss after use and extended the mask dry out time by 1~3 mins. In summary, the panel preferred facial masks containing HEC. During the experiment we introduced a new method to quantitatively test the softness of facial masks which involved using a texture analyzer and a spherical probe P1S to simulate the process of a finger pressing the mask. The results obtained through the use of this method were consistent with the results of the sensory evaluation. In addition, we established a systemic equipment test and human sensory evaluation method for facial mask products. We reported on the compatibility of mask fabrics and mask serums for the first time and also confirmed that HEC has a valid application in facial mask products.

[1] Mintel report. Facial Skincare China-August 2016. Mintel Group Ltd, 2016.

[2] Wang Lei; Wu Xujun; Chen Shiyan; et al. Preparation of hyaluronic acid-bacterial cellulose biological mask by in situ modification. Materials Review B: Research Paper 2015, 29(6),43-47.

[3] Bai Xiaoyun; Fu Yicai; Niu Wenxia; et al. Comparison of efficacy for six commercial facial-masks. Flavour Fragrance Cosmetics 2013, 6, 51-54.

[4] Zhu Liping; Sun Changlei; Li Zian. The clinical effect and analysis of ginseng anti-aging facial mask. Chinese Journal of Aesthetic Medicine 2016, 25(2), 33-36.

[5] Zhang Guanghua; Wang Yiwei; Li Hui. Properties and application of cellulose ethers in daily chemical industry.Detergent & Cosmetics 2007, 30(10), 15-17.

[6] Zhu Ganghui. Application of sodium carboxymethyl cellulose and hydroxyethyl cellulose for daily chemicals. Detergent &Cosmetics 2005, 28(4), 16-20.

[7] Tai A; Bianchini R; Jachowicz J. Texture analysis of cosmetic/pharmaceutical raw materials and formulations. International Journal of Cosmetic Science 2014, 36, 291-304.

[8] Fustier P; Castaigne F; Turgeon SL; et al. Impact of commercial soft wheat flour streams on dough rheology and quality attributes of cookies. Journal of Food Engineering 2009, 90,228-237.

[9] Velasco MVR; Vieira RP; Fernandes AR; et al. Short-term clinical of peel-off facial mask moisturizers. International Journal of Cosmetic Science 2014, 36, 355–360.

China Detergent & Cosmetics2018年2期

China Detergent & Cosmetics2018年2期

- China Detergent & Cosmetics的其它文章

- Application of “Youthful Curve of Ocular Region” in the Research of Asians Aging

- Latest Update of Cosmetic Regulations in China Since 2017

- How to Comply with the Pilot Policy of China for the Import of Non-special Use Cosmetics

- 2017 Cosmetic Regulatory News in AP

- Analysis of Regulatory Policies and Registration / Record Keeping Status of Domestic Cosmetics in China

- Middle Class pivotal to China’s Beauty Market