Research on the Preparation of an Anti-Acne Cream and its Thermal Stability

Li Xilian, Jia Bing, Chen Minghua

Jala Group Co., Shanghai, China

Abstract In this paper, the preparation of tea tree oil and salicylic acid anti-acne cream was studied. The single emulsifier, compound emulsifier, thickener in the acidic system were screened, and the long-term thermal stability was investigated. The experimental results show that when the ether emulsifier, NIKKOL BC-150 and MONTANOV 68, is compounded in a mass ratio of 2:1 and the thickener is SEPIPLUS 400, the obtained product has good thermal stability, and its functional ingredients (tea tree oil and salicylic acid) did not change significantly at high temperatures.

Key words anti-acne cream; tea tree oil; salicylic acid; emulsifier; thickener; thermal stability

Tea tree oil (TTO), also known as Australian liquid gold, is obtained from several plants of the My rtaceae of Melal euca L.[1]At present, more than 100 kinds of ingredients have been extracted from tea tree oil,mainly monoterpenoids, sesquiterpenoids and their derivatives, among which terpineol-4, γ-terpinene,and α-terpinene are the main ones.[2]In recent years,the research on the antibacterial effect of tea tree oil has become an international research hotspot.[3]TTO is used in cosmetics and has antibacterial and antiin flammatory properties with low irritation.[4]

Salicylic acid (SA, o-hydroxybenzoic acid) is a simple phenolic compound used in cosmetics, which has the effect of whitening and anti-acne.[5]

At present, salicylic acid is added to the mainstream anti-acne products internationally, but there is few research on the combination of tea tree oil and salicylic acid as functional ingredients in the cream. Especially in the acidity system with high tea tree oil content whose pH value is about 3.0, the stability of the emulsifier and the product are both difficult points in the formulation technology. In this paper, the emulsifier and thickener were screened, and the long-term thermal stability was studied.

Experiment

Main reagents and instruments

Cetearyl alcohol / cetearyl glucoside (MONTANOV 68, SEPPIC); Behenyl alcohol-25 (Eumulgin BA25,BASF); Ceteareth-25 (BRIJ CS25-PA-(SG), CRODA);PEG-100 stearate/glyceryl stearate (TEGOCARE 165,EVONIK); Cetearyl alcohol oleate/sorbitan olive oil(OLIVEM 1000, B&T); Cetyl alcohol polyether-40(NIKKOL BC-40, NIKKOL Chemicals); Cetyl alcohol polyether-150 (NIKKOL BC-150, NIKKOL Chemicals);MELALEUCA ALTERNIFOLIA leaf oil (TEA TREE OIL, DOWNUNDER); Salicylic acid (RONACARE SALICYLIC ACID, MERCK); Polyacrylamide/water/C13-14 isoparaffin/laureth-7 (SEPIGEL 305, SEPPIC);Polyacrylate-13/polyisobutylene/polysorbate-20/sorbitan stearate/water (SEPIPLUS 400, SEPPIC); Tetrahydrofuran(Fisher Chemical); Methanol (CNW); Phosphoric acid (GR,Sinopharm Group); Isooctane (CNW).

J.K.ROBOMICS high shear emulsification disperser (Primix China); METTLER TOLEIDO TE20K Plus pH meter (METTLER TOLEDO (Shanghai) Co.,Ltd.); Nikon ECLIPSE 50i POL Electron Microscope(Shanghai Henghao Instrument Co., Ltd.); Brook field VISCOMETER DV2T Viscometer (Brookfield Engineering Labs., Inc.); Eurostar Power CV Eurostar Mixer (IKA), HPLC 1200 (Agilent, USA), GC7890 (Agilent, USA).

Experimental method

Formulation sample preparation

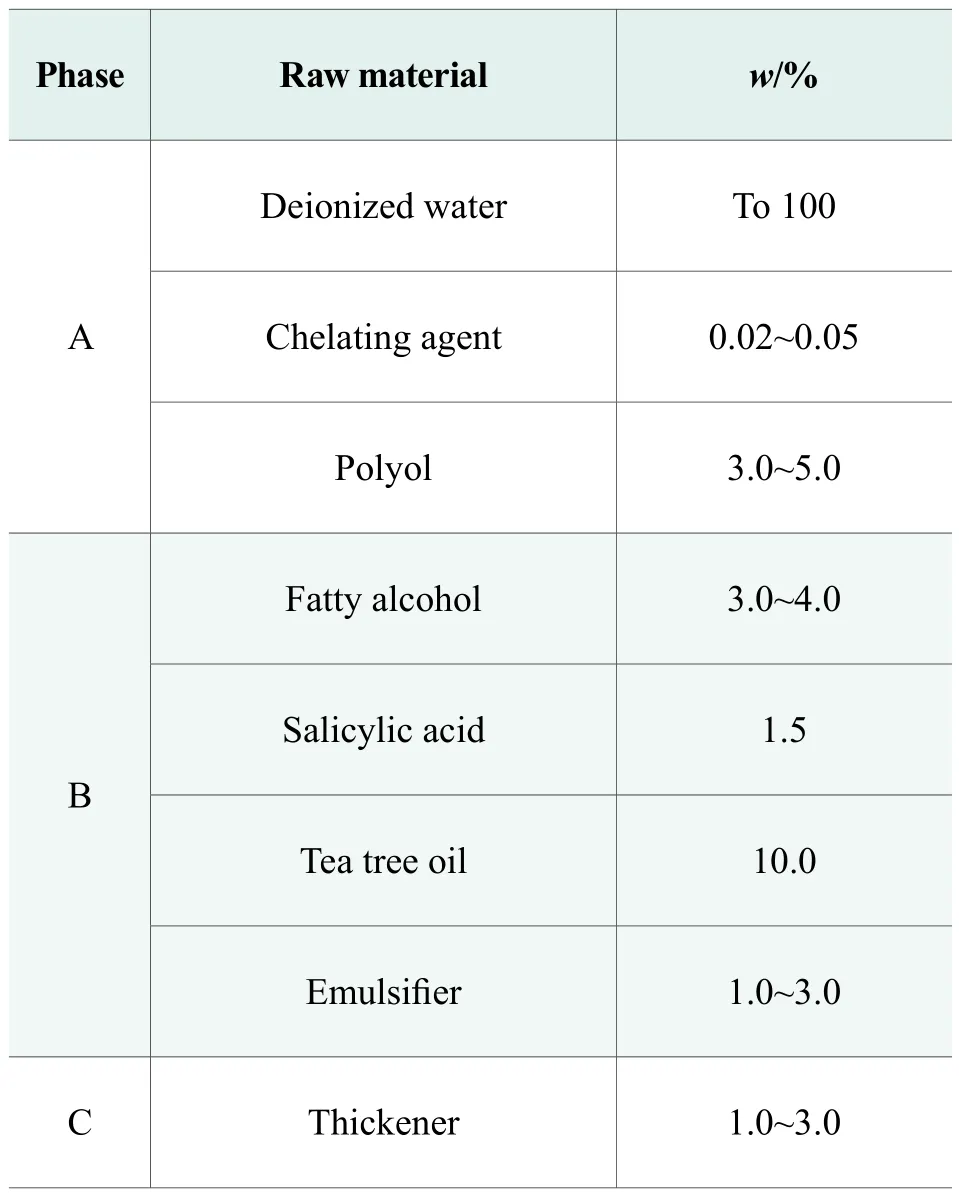

Accurately weigh according to Table 1, place the water phase (A) in a water bath and stir to heat to 80-85 °C; stir the oil phase (B) to 80-85 °C and melt evenly; then add phase A to phase B while stirring.Mix well and homogenize for 5 min at high speed,then add phase C for high-speed homogenization for 3 mins, then continue stirring and cool naturally, and cool to 30 °C for discharge.

Table 1. Ingredients of the anti-acne cream

Liquid chromatographic sample preparation and chromatographic conditions

Accurately weigh 0.5 g of salicylic acid in a 50 mL volumetric flask, disperse with 10 mL of tetrahydrofuran,dilute to the mark with methanol and shake well. Use 0.45 μm hydrophobic polytetra fluoroethylene (PTFE)filter head to filter the appropriate amount into the liquid chromatography.

Chromatographic conditions: chromatographic column:Waters Symmetry Shield RP18, 4.6 mm×150 mm×5 μm;Detection wavelength: 230 nm; Column temperature:30 ℃; Mobile phase: V (methanol): V (0.1%phosphoric acid aqueous) = 60:40; Injection volume:5 μL; Detector: Diode array detector.

Gas chromatographic sample preparation and chromatographic conditions

Use pipette to take 100 μL of tea tree oil sample,place in a 10 mL volumetric flask, dissolve with isooctane, dilute to scale and shake. The organic phase filter is filtered and used as a solution to be tested.

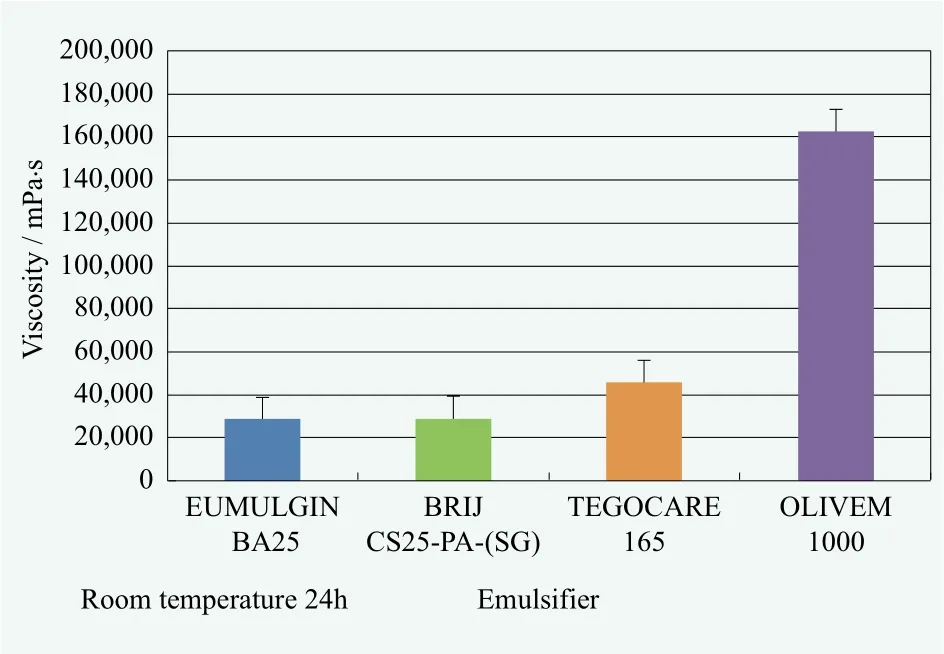

Chromatographic conditions: chromatographic column:J & W HP-INNOWAX 260 °C: 30 m × 320 μm × 0.25 μm;Column flow: 1.0 mL/min; Carrier gas: N2; Injection volume: 1 μL; Injection port temperature: 250 ℃;Column temperature: Temperature programming.

Detector temperature: 280 ℃; Split ratio: 5:1.

Viscosity and thermal stability test

Viscosity test

The auto-zero must be conducted before the viscometer test. The operator must ensure that the viscometer is horizontally placed and remove all rotors and connectors. When the “Next” button is pressed,the viscometer will run for 13 s approximately. After auto-zeroing, the operator presses the “Next” button and the viscometer will go to the Configure Viscosity Test page. The operator should choose T-D (94) at a speed of 5 r/min, then install the Brook field standard viscometer on the driven motor of the lift bracket and connect the T-rotor to the viscometer through the connector. Drive the motor slowly to move the viscometer up and down. The T-shaped rotor creates a spiral path in the test sample. Finish the test within a specified time and observe the viscosity.

Thermal stability test

To meet the requirements of 2-year quality guarantee period of the product, the FDA has accepted a specific accelerated stability test. In some cases, the product is placed at 50 °C for one month, and the results can fully support the conclusion of the accelerated stability test. The sample prepared above was subjected to thermal stability test, and the viscosity change under high temperature (50 °C) condition was investigated.Comparing with the room (normal) temperature, the change trend was observed. The samples were taken out from a high-temperature oven for 2 weeks and 4 weeks respectively, and then placed in a 25 °C oven to be tested for viscosity after it returns from 50 °C to room temperature (25 °C).

Results and analysis

Effect of emulsifier categories on emulsification results

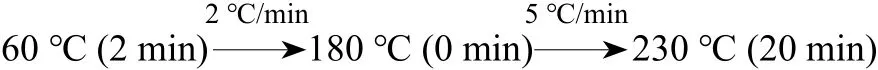

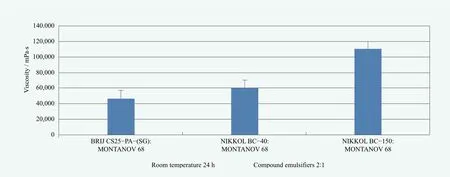

The emulsifiers in Table 1 include alkyl glycosides(MONTANOV 68), ethers (EUMULGIN BA25, BRIJ CS25-PA-(SG)), esters (TEGOCARE 165, OLIVEM 1000). Their volume is 3.0%. The thickener is 2.5%SEPIGEL 305. It can be seen from the experiment result that the sample prepared by using MONTANOV 68 as an emulsifier is rough in form with a relatively thin viscosity. Its emulsification is incomplete, and the emulsifying ability is weak. The viscosity of the sample prepared by other emulsifiers after placing at room temperature for 24 h has been shown in Figure 1.

Figure 1. Effects of single emulsifier on viscosity

It can be seen from Figure 1 that there is no significant difference in the viscosity of the products prepared by EUMULGIN BA25 and BRIJ CS25-PA-(SG),mainly because that although the two emulsifiers have different hydrophobic carbon chain lengths, they didn't appear too much different and their structure is similar. TEGOCARE 165 and OLIVEM 1000 are ester emulsifiers; but the latter has a significantly higher sample viscosity than the former, probably because the latter contains part of fatty alcohol derivatives. The sample using OLIVEM 1000 as an emulsifier is with a high initial viscosity and a creamy appearance. The other emulsifiers performed a lower viscosity.

Effect of thickener categories on viscosity

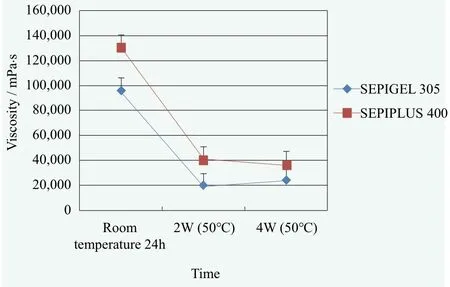

The pH of the product using ester emulsifier OLIVEM 1000 as the single emulsifier was about 3. Acid-resistant thickeners SEPIGEL 305 and SEPIPLUS 400 were selected for the experiment,whose samples were tested for thermal stability respectively under observation of high-temperature for 4 weeks. The experimental results have been shown in Figure 2.

Figure 2. Effects of different thickeners on viscosity

SEPIGEL 305 and SEPIPLUS 400 are the same types of thickener (no neutralization required),but the latter has higher active content. It can be seen from Figure 2 that the initial viscosity of the product prepared by SEPIPLUS 400 is high, but the viscosity of the product is greatly dropped after 2 weeks of storage, and the thermal stability of the product is poor. The possible reason is that the ester emulsifier structure contains an ester bond, and partial hydrolysis occurs at a lower pH value to lose the emulsification, resulting in system instability.

The above analysis shows that acid-resistant thickener is effective for this system, and the thicker SEPIPLUS 400 with higher initial viscosity can be selected.

Emulsifier compounding

According to the first two parts in “Results and andysis”, MONTANOV 68 has a weak emulsifying ability as a single emulsifier, and ester emulsifiers have poor long-term thermal stability.

The alkyl glycoside emulsifier actually belongs to ether, and the fatty alcohol polyether emulsifier has the structural formula R(OCH2CH2)nOH(wherein R is a C12-C18 alkyl group, n=2~50).[7]The emulsifier only contains ether bond structure,but not ester bond structure. It has good acidbase stability. Therefore, the two emulsifiers are compounded. The structures of BRIJ CS25-PA-(SG),NIKKOL BC-40, and NIKKOL BC-150 emulsifiers are similar, and the EO value is gradually increased.Compounding with MONTANOV 68 by 2:1 of mass ratio. The initial viscosity of the sample prepared has been shown in Figure 3.

In terms of Figure 3, as the value of EO rises, the viscosity of the sample prepared by the corresponding emulsifier gradually increases. The reason is that a nonionic surfactant containing a polyoxyethylene chain, when the alkyl chain length is constant, the number of micelle aggregation decreases as the polyoxyethylene chain grows. As the length of the EO chain increases, the more the water-soluble groups in the non-ionic emulsifier molecules diffuse into the aqueous phase, the more the number of latex particles finally formed in the system,[9]which increases the viscosity of the system.

It can be seen from Figure 3 that the product obtained by compounding NIKKOL BC-40,NIKKOL BC-150 and MONTANOV 68 has a high initial viscosity and performs as creamy substance.

Thermal stability

Thermal stability of efficacy component

The product's functional ingredients are salicylic acid and tea tree oil, which are placed at high temperature for one month to test the salicylic acid content. It can be seen from Table 1 and the experimental results that the salicylic acid content (1.58%) at a high temperature for one month is less than that in normal temperature(1.57%), namely, the salicylic acid content in the product has no significant change, which is in accordance with the theoretical value and has good stability.

Figure 3. Effects of compound emulsifiers on viscosity

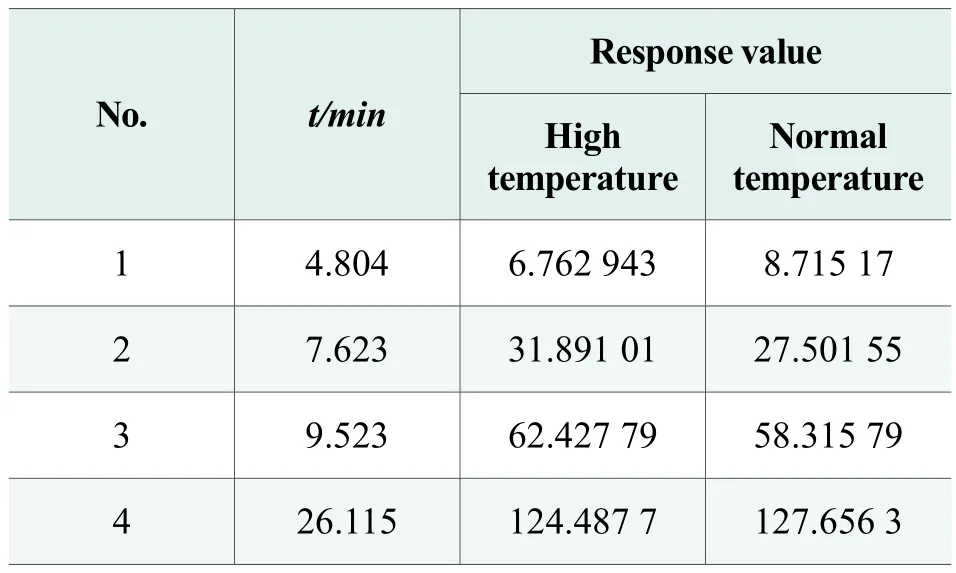

The chemical composition of tea tree oil is complicated with four main peaks. The gas chromatogram comparison shows that the response value of the main peak of tea tree oil in the sample at normal temperature and high temperature (the peak area corresponding to the concentration of 1 mol/L) is shown in Table 2. It can be seen that there is no significant change in the main peak response of tea tree oil at high temperature, namely, tea tree oil has good stability at high temperature.

Table 2. Comparison of response values of tea tree oil

Thermal stability of product

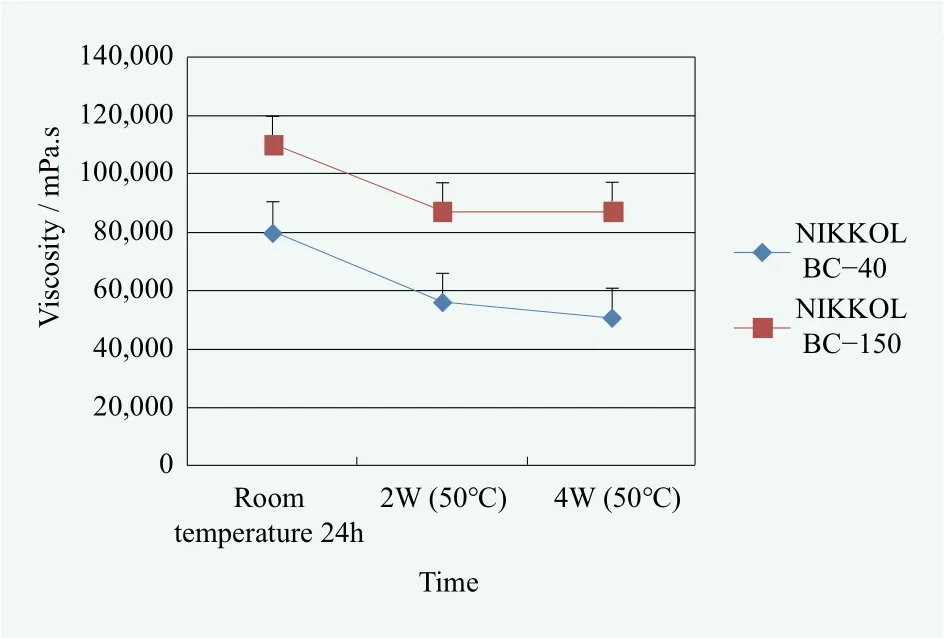

The thermal stability test results of NIKKOL BC-40 and NIKKOL BC-150 with MONTANOV 68 compound system are shown in Figure 4.

Figure 4. Effects of two emulsifiers on thermal stability

It can be seen from Figure 4 that the viscosity drop of the product at a high temperature for 4 weeks was not obvious. The initial viscosity of NIKKOL BC-150 was high. There is no significant change in viscosity for 2 and 4 weeks after high-temperature test. The microstructure observation shows no significant difference in particle size compared with that in room temperature. It has relatively good stability. Namely, the composite emulsifier molecules are arranged at intervals, which obtains higher packing density, thereby increasing the interface strength and obtaining a better stabilizing effect.

Conclusion

In an acidic system containing both tea tree oil and salicylic acid, the ester emulsifier may hydrolyze,resulting in poor long-term thermal stability; the acid-resistant thickener is effective for this system,and the thicker SEPIPLUS 400 with higher initial viscosity can be selected for it. The compound of fatty alcohol polyether emulsifier and alkyl glycoside,namely, ether compounding, whose product stability is good at high temperature. The functional content of salicylic acid and tea tree oil in the product has almost no obvious change at high temperature for one month, indicating that the stability is good.

China Detergent & Cosmetics2019年1期

China Detergent & Cosmetics2019年1期

- China Detergent & Cosmetics的其它文章

- The Methodology of Cosmetics Efficacy Evaluation to Provide Scientific Support for Soothing Skin Efficacy Claims

- Determination of Bemegride and its Salts in Cosmetics by HPLC and Their Verification by HPLC-MS/MS

- Fluorinated Surfactants and Fluorinated Polymer Materials (i):General Review

- Research Progress on the Relationship between Skin Microbial Flora and Skin Health

- Determination of 24 Allergens in Perfume with High Performance Liquid Chromatography Tandem Mass Spectrometry

- Comparison of HPLC-DAD and GC-FiD Methods for Determination of 6-Methyl Coumarin in Cosmetics