Flexible and Robust Functionalized Boron Nitride/Poly(p-Phenylene Benzobisoxazole) Nanocomposite Paper with High Thermal Conductivity and Outstanding Electrical Insulation

Lin Tang, Kunpeng Ruan, Xi Liu, Yusheng Tang?, Yali Zhang, Junwei Gu?

ABSTRACT With the rapid development of 5G information technology, thermal conductivity/dissipation problems of highly integrated electronic devices and electrical equipment are becoming prominent.In this work, “high-temperature solid-phase & diazonium salt decomposition” method is carried out to prepare benzidine-functionalized boron nitride(m-BN).Subsequently, m-BN/poly(pphenylene benzobisoxazole) nanofiber(PNF) nanocomposite paper with nacremimetic layered structures is prepared via sol–gel film transformation approach.The obtained m-BN/PNF nanocomposite paper with 50 wt% m-BN presents excellent thermal conductivity, incredible electrical insulation,outstanding mechanical properties and thermal stability, due to the construction of extensive hydrogen bonds and π–π interactions between m-BN and PNF, and stable nacre-mimetic layered structures.Its λ// and λ⊥ are 9.68 and 0.84 W m-1 K-1, and the volume resistivity and breakdown strength are as high as 2.3 × 1015 Ω cm and 324.2 kV mm-1, respectively.Besides, it also presents extremely high tensile strength of 193.6 MPa and thermal decomposition temperature of 640 °C, showing a broad application prospect in high-end thermal management fields such as electronic devices and electrical equipment.

KEYWORDS Poly(p-phenylene-2,6-benzobisoxazole) nanofiber; Boron nitride; Thermal conductivity; Electrical insulation

1 Introduction

Thermally conductive polymer-based composite paper has attracted widespread attention in the fields of lithium batteries, capacitors and integrated circuits [1–4], due to the advantages of high strength, high thermal conductivity and excellent designability, etc.With the rapid development toward miniaturization and integration, as well as increasing power density, the build-up of heat inside electronic devices and electrical equipment is getting serious, which puts forward higher requirements for the thermal conductivity and heat resistance of thermally conductive polymerbased composite paper [5–7].Moreover, in order to avoid the formation of short-circuit currents between microelectrical components and the mutual interference of signals, the polymer-based composite paper should possess outstanding electrical insulation to meet the application in practical electronic engineering [8–10].Although thermally conductive polymer matrix (polytetrafluoroethylene, polyimide, aramid and cellulose nanofibers, etc.) composite paper has been widely used in industry owing to their low-cost and simple processing technology, the intrinsically poor heat resistance,or poor mechanical properties, or low thermal conductivity limits their application and no longer guarantees the stability and reliability in the fields of thermal management for highend electronics and electrical appliances [11–13].

Among the known organic fibers, poly(p-phenylene-2,6-benzobisoxazole) (PBO) fibers present the highest thermal decomposition temperature (650 °C), the best tensile strength (5.8 GPa) and tensile modulus (280 GPa) and have been hailed as the super fiber of the twenty-first century[14–16].Recent studies exhibit that PBO nanofibers (PNF)obtained by organic acid stripping can retain the excellent mechanical properties and heat resistances of PBO fibers[17–20].In addition, their interior contains highly oriented molecular chains and original crystallinity, showing better thermal conductivity than ordinary polymer matrix, which shows a broad application prospect in the field of thermally conductive polymer-based composite paper.Li et al.[21] reported a series of fluorinated graphene (FG)-based nanocomposite films containing robust PNF network structures via unique sol–gel film conversion method.The nanocomposite film with 40 wt% FG possessed high in-plane thermal conductivity coefficient (λ//, 12.3 W m-1K-1),392% higher than that of pure PNF paper (2.50 W m-1K-1).Zhao et al.[22] introduced boron nitride (BN) and MXene sequentially into the PNF networks to prepare PNF/BN/MXene composite paper via gel microparticle-mediated ordered assembly process with the aid of vacuum-assisted filtration.When the amounts of BN and MXene were 29.2 and 41.7 wt%, respectively, theλ// of PNF/BN/MXene composite paper was 26.10 W m-1K-1, significantly higher than that of pure PNF paper (2.92 W m-1K-1).Nevertheless,the introduction of functional fillers (such as graphene and MXene) can drastically decrease the electrical insulation of PNF-based composite paper [23–26], limiting its broader application in electrical and electronic fields.It remains a great challenge to develop high-performance PNF-based composite paper with excellent thermal conductivity and electrical insulation.

BN presents excellent thermal conductivity, electrical insulation and heat resistance, showing good application prospects in the thermal management fields of electronic and electrical [27–31].Yu et al.[32] prepared BN/epoxy composites by blending BN with epoxy resin.When the amount of BN was 11.9 wt%, the thermal conductivity coefficient (λ) of BN/epoxy composites increased from 0.21 to 0.51 W m-1K-1, and the breakdown strength increased from 40.9 to 58.6 kV mm-1.Yang et al.[33]reported the facile and scalable approach to fabricate elastomeric silicone rubber (SiR)/graphene nanoparticles (GNPs)/BN composites with an alternating multilayer structure, achieving highλof 8.45 W m-1K-1and excellent electrical insulation properties (volume resistivity of about 1013Ω cm and breakdown strength of 5.33 kV mm-1).However, the enhancement of thermal conductivity was limited due to the high interfacial thermal resistance between BN and BN fillers, as well as BN and polymer matrix [34–36].In our previous work,Gu et al.[37] calculated the interfacial thermal resistance between fillers and polymer matrix based on the modified Hashin–Shtrikman model and effective medium theory,revealing that the surface-functionalized fillers could further improve theλof thermally conductive composites with the same amount of fillers.Therefore, the surface functionalization of BN is the key factor for reducing interfacial thermal resistance and further improving theλof corresponding thermally conductive composites.

To our knowledge, the surface functionalization methods of BN fillers are mainly classified into non-covalent modification and covalent modification [38–40].The former utilizes van der Waals force and electrostatic adsorption, etc., to coat the surface of BN with a layer of organic matter [41–43].However, the functionalized BN prepared by the non-covalent modification is unstable.Covalent modification is to destroy B–N bond on the surface of BN by plasma, ultrasonic treatment, strong acid, and strong base to form stable hydroxyl and amino groups [44–46].Kim et al.[47] carried out ultrasonic treatment of BN and then adopted (hexadecyl)trimethoxysilane to modify the surface of BN (C16-BN).C16-BN/epoxy composites with 20 wt% C16-BN presented excellentλ(3.49 W m-1K-1),45.4% higher than that of 20 wt% BN/epoxy composites(2.40 W m-1K-1).Zhang et al.[48] adopted KOH/NaOH to treat BN by the high-temperature solid-phase method to obtain BN-OH and subsequently blended with polystyrene(PS) to prepare BN-OH/PS composites.The native structure of BN-OH was not damaged.When the amount of BN-OH was 12 wt%, the BN-OH/PS composites presented excellent thermal conductivity withλof 1.13 W m-1K-1,52.7% higher than that of 12 wt% BN/PS composites(0.74 W m-1K-1).

In this work, PBO fibers are stripped in the methanesulfonic acid (MSA)/trifluoroacetic acid (TFA) solution to obtain PNF.Benzidine is performed to functionalize the surface of BN (m-BN), followed by blending with PNF to prepare them-BN/PNF nanocomposite paper via sol–gel film transformation approach.X-ray diffractometer (XRD), X-ray photoelectron spectroscopy (XPS), scanning electron microscope (SEM) and transmission electron microscope (TEM)are utilized to analyze and characterize the surface elements,crystal structures and micromorphologies ofm-BN and PNF.On this basis, the functionalization ofm-BN and its amount influencing on thermal conductivities, electrical insulation and mechanical properties of them-BN/PNF nanocomposite paper are analyzed.

2 Experimental Section

2.1 Surface Functionalization of BN

Benzidine is performed to functionalize the surface of BN(m-BN) by “high-temperature solid-phase & diazonium salt decomposition” method.The B–N on the surface of BN can be destroyed to generate hydroxyl and amino groups (HOBN) via high-temperature solid-phase method [49] at concentrated alkaline environment.The high activity of benzidine carbocation produced by decomposition of diazonium salt is utilized to graft benzidine onto the surface of HO-BN(m-BN).The surface functionalization mechanism ofm-BN is shown in Fig.S1, and the specific process is as follows.

One gram of BN, 1.5 g of sodium hydroxide and 1.5 g of potassium hydroxide were ground into powder, reacting in a hydrothermal reactor at 180 °C for 5 h.Subsequently,the reactants were dissolved in distilled water and washed for 2–3 times until the solution was neutral, followed by drying at 60 °C for 24 h to obtain HO-BN.Next, 3.7 g of benzidine was dissolved in distilled water, stirred in an ice bath, and an appropriate amount of hydrochloric acid was added to form amaranth suspension.Then, 1.4 g of sodium nitrite was slowly added into the above solution to form a diazonium chloride salt solution.Finally, 0.5 g of HO-BN was added into the diazonium chloride salt solution, 2.0 g of iron powder and an appropriate amount of hydrochloric acid were added sequentially, and the reaction was carried out at ice bath environment for 2 h.The reactants were washed with distilled water and methanol to remove excess diazonium chloride salts, followed by drying at 60 °C for 24 h to obtainm-BN.

2.2 Fabrication of the m-BN/PNF Nanocomposite Paper

PBO fibers were added into the MSA/TFA solution with a volume ratio of 1:1, followed by stirring for 24 h to form PNF dispersion.Appropriate amount ofm-BN and 1.5 g of Na2SO4were added into 30 g of PNF dispersion (0.1 wt%)and magnetically stirred for 2 h.Subsequently, 10 g of PNF dispersion (1 wt%) was continued to be added, and them-BN/PNF acid sol was obtained by high-speed homogeneous stirring.The acid sol was poured into a culture dish and stood for 24 h to obtainm-BN/PNF acid gel.Then, them-BN/PNF acid gel was soaked in distilled water for multiple solvent exchange, to obtain them-BN/PNF hydrogel, which was then compressed and dried to obtainm-BN/PNF nanocomposite paper.The schematic diagram of the preparation process is shown in Fig.1a.A series ofm-BN/PNF-X nanocomposite paper was fabricated by changing the mass ratio ofm-BN to PNF (X represented the mass fraction ofm-BN, which were 10, 20, 30, 40 and 50, respectively).In addition, a series of BN/PNF-X composite paper was prepared by the same method for comparative analyses.

3 Results and Discussion

3.1 Structures and Morphologies of m-BN/PNF Nanocomposite Paper

Figure 1b shows the SEM image and optical photograph of PBO fibers.PBO fibers have been gradually exfoliated in the mixed acid of MSA/TFA, becoming brown PNF dispersion (Fig.1c).Figure 1d, d′ shows the TEM images of high-aspect-ratio PNF with diameter ranging from 10 to 40 nm.Nitrogen and oxygen atoms on PBO molecular chains are protonated by the mixed acid, which increases the electrostatic repulsion between the molecular chains, resulting in the gradual stripping of PBO fibers to PNF.Meanwhile, some oxazole rings on the PBO molecular chains are broken to generate hydroxyl and amino groups (Fig.S2).

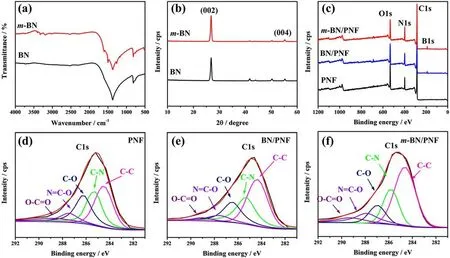

Fig.2 FTIR (a) and XRD (b) spectra of m-BN and BN; XPS wide-scan spectra (c) and high-resolution C 1s XPS spectra (d–f) of PNF paper,BN/PNF and m-BN/PNF nanocomposite paper

The yellowm-BN/PNF acid sol (Fig.1c′) is formed by addingm-BN and Na2SO4into the PNF dispersion.The acid sol has been poured into a culture dish and stood for 24 h to obtainm-BN/PNF acid gel with certain flexibility (Figs.S3a,a′ and 1e, e″).On the contrary, the pristine PNF dispersion shows no significant changes after standing for 24 h.As can be seen in Fig.1f, f′,m-BN and PNF form a stable threedimensional (3D) crosslinked network structures, and PNF is tightly attached onto the surface ofm-BN.The network is created because the SO42-shields the positive charge on the surface of PNF, which suppresses electrostatic exclusion and enhances the π–π interactions between PNF, leading to crosslinking for gelation (Fig.S4a, a′).In addition, amino groups and biphenyls on the surface ofm-BN form strong hydrogen bonds and π–π interactions with PNF (Fig.1g),causing PNF to adhere closely onto the surface ofm-BN.However, original BN forms obvious defects in 3D network structure of PNF owing to weak interaction (Fig.S4b, b′).

Them-BN/PNF nanocomposite paper presents excellent flexibility and folding resistance, with no obvious damage after being bent for 180 degrees or folded into a bow(Fig.1h–h″).As shown in Fig.1i, i′, based on the hydrogen bonds and π–π interactions,m-BN/PNF nanocomposite paper displays an orderly arrangement ofm-BN in the inplane direction.A large amount of PNF is tightly stacked and interconnected between them-BN in the through-plane direction, resulting in stable nacre-mimetic layered structures inside the nanocomposite paper (Fig.S5).Besides,m-BN is uniformly distributed on the surface of them-BN/PNF nanocomposite paper, and PNF on the surface is interlaced with each other to form a porous nanofiber network structure(Fig.S6).

Figure 2a, b shows Fourier transformed infrared (FTIR,a) and XRD (b) spectra of the BN before and after functionalization.BN shows obvious absorption peaks at 811 and 1376 cm-1(Fig.2a), corresponding to the stretching and bending vibration absorption of B–N, respectively [50,51].Compared with BN,m-BN appears new characteristic absorption peaks at 1608 and 1500 cm-1, mainly attributed to the stretching vibration peak of biphenyls.Characteristic absorption peak corresponding to the amino group appears at 3400 cm-1, which proves that benzidine is successfully grafted on the surface of BN.As can be seen from the highresolution XPS spectra of N1s before and after BN functionalization (Fig.S7a, b), in addition to the B–N peak corresponding to BN (397.4 eV, Fig.S7a),m-BN also shows a new split peak corresponding to the C–N peak at 399.1 eV(Fig.S7b), further proving that benzidine is successfully grafted on the surface of BN.Figure S7c shows the thermogravimetric analyses (TGA) curves of BN andm-BN.The weight of BN does not change significantly in the range of 40–800 °C, while the weight loss ofm-BN increases with increasing temperature.When the temperature rises to 800 °C, the weight loss rate ofm-BN is about 2.6 wt%, due to the oxidation decomposition of benzidine.As can be seen from Fig.2b, both BN andm-BN present XRD diffraction peaks of the same size, corresponding to 26.6° (002) and 55.2° (004) [52–54].The morphology (Fig.S8) of them-BN is basically unchanged, compared with that of BN.Results show that “high-temperature solid-phase & diazonium salt decomposition” method does not destroy the crystal structure of BN.

Figure 2c shows XPS spectra of PNF paper, BN/PNF andm-BN/PNF nanocomposite paper.The surface of PNF paper mainly contains C, N and O elements.Compared to PNF paper, BN/PNF andm-BN/PNF nanocomposite paper shows new B elements attributed to the introduction of BN orm-BN.C 1sspectra in Fig.2d–f demonstrate the existence of abundant polar C–N and C–O groups for PNF paper, BN/PNF andm-BN/PNF nanocomposite paper.Notably, the characteristic peaks at 285.2, 286.4 and 287.6 eV for the C–N, C–O and N=C–O groups of PNF paper, BN/PNF nanocomposite paper shift to a higher binding energy of 285.8, 286.9 and 288.3 eV form-BN/PNF nanocomposite paper, respectively.Results indicate that the chemical environments for C–N, C–O and N=C–O groups ofm-BN/PNF nanocomposite paper have been changed, demonstrating the formation of hydrogen-bonding interaction betweenm-BN and PNF.

3.2 Thermal Properties of m-BN/PNF Nanocomposite Paper

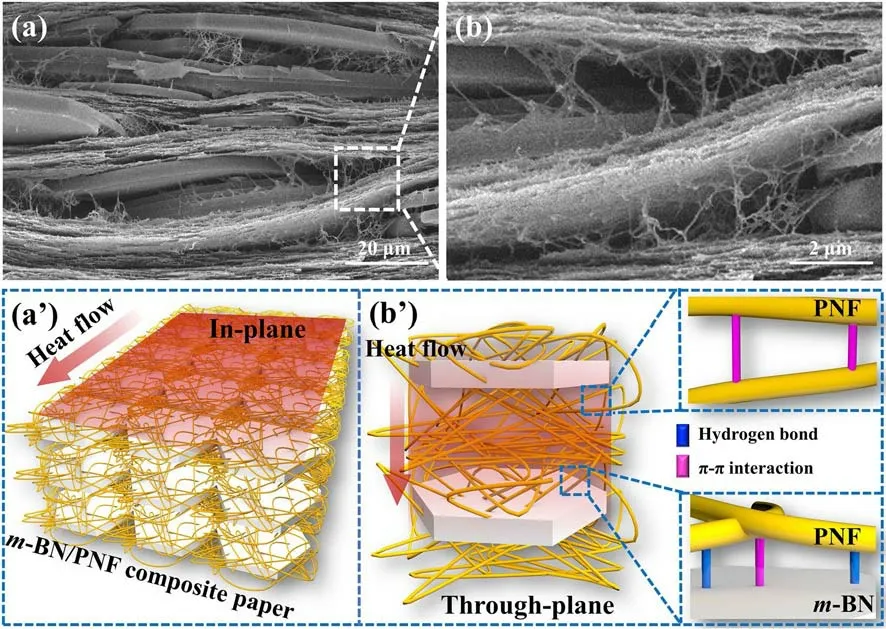

Figure 3a, b shows theλ// and through-plane thermal conductivity coefficient (λ⊥, b) ofm-BN/PNF nanocomposite paper, respectively.Theλ// andλ⊥ofm-BN/PNF and BN/PNF nanocomposite paper all increase with the increasing amount ofm-BN and BN, mainly due to the fact that the formation probability of thermal conduction pathway increases gradually inner PNF matrix, and the thermal resistance of heat conduction along thermal conduction pathway decreases gradually [55].Under the same amount ofm-BN and BN, theλ// andλ⊥of them-BN/PNF nanocomposite paper are both higher than those of the BN/PNF nanocomposite paper.When the mass fraction ofm-BN is 50 wt%,m-BN/PNF-50 nanocomposite paper presents the highestλ//andλ⊥of 9.68 and 0.84 W m-1K-1, respectively, increased by 393% and 494% compared with those of PNF paper,25.4% and 18.3% higher than theλ// (7.72 W m-1K-1) andλ⊥(0.71 W m-1K-1) of the BN/PNF nanocomposite paper with the same amount of BN.It can be indicated that them-BN presents significant influences on improving the thermal conductivities.This is because the amino groups and biphenyls on the surface ofm-BN form strong hydrogen bond and π–π interaction with PNF, resulting in the lower interfacial thermal resistance of nanocomposite paper.Them-BN is uniformly arranged in the in-plane direction of them-BN/PNF nanocomposite paper (Fig.4a), which can form effi-cientm-BN thermal conduction pathway (Fig.4a′).Besides,them-BN is interconnected with a large number of PNF in the through-plane direction (Fig.4b), which effectively reduces the interfacial thermal resistance betweenm-BN,and drastically improves the phonon propagation efficiency(Fig.4b′).In contrast, BN is partially agglomerated in the PNF matrix, which cannot form efficient BN thermal conduction pathway, and inevitably introduce the interfacial thermal resistance of BN-BN or BN-PNF [47, 56].Therefore, BN/PNF nanocomposite paper presents relatively lowerλ// andλ⊥than those ofm-BN/PNF nanocomposite paper with the same amount of fillers.

To further elucidate the effect of surface functionalization for BN on the interfacial thermal resistance andλof them-BN/PNF nanocomposite paper, the experimentally obtainedλ// andλ⊥of BN/PNF andm-BN/PNF nanocomposite paper are fitted by the modified Hashin–Shtrikman model [57–59](Fig.S9).The in-plane thermal resistance () and throughplaneofm-BN/PNF nanocomposite paper are 0.2336 and 0.2258, respectively, lower than those of BN/PNF nanocomposite paper (in-planeof 0.2443 and through-planeof 0.2317), which further demonstrates that the reduction of interfacial thermal resistance plays a crucial role in improving the thermal conductivity of the nanocomposite paper.Figure S10 shows theλ// andλ⊥of PNF paper andm-BN/PNF-50 nanocomposite paper at different temperature (20–200 °C).Theλ// andλ⊥of PNF paper andm-BN/PNF-50 nanocomposite paper all increase slightly with the increasing temperature.This is because as the temperature increases, the phonon transmission speed increases, contributing to the improvement of thermal conductivities [60].

Figure 3c, c′ shows the curves of temperaturesvs.time for heating resistor on air, PNF paper andm-BN/PNF-50 nanocomposite paper, and corresponding infrared thermal images.The surface temperature of the heating resistor rises sharply to about 90 °C after 20 s of operation at 10 V.Subsequently, the surface temperature gradually decreases after the heating is stopped, and eventually decreases to below 40 °C.When the air and PNF paper are used as the heat dissipation materials, the surface temperatures of the heating resistor after heating 20 s are 88.3 and 87.1 °C, respectively,higher than the surface temperature of 84.5 °C whenm-BN/PNF-50 nanocomposite paper is used as the heat dissipation material.The main reason is thatm-BN/PNF nanocomposite paper can effectively dissipate part of the accumulated heat during heating, due to its excellent thermal conductivity.After cooling for 30 s, the surface temperature of the heating resistance withm-BN/PNF-50 nanocomposite paper as the heat dissipation material is as low as 26.2 °C, much lower than those of air (32.7 °C) or PNF paper (38.3 °C).

Fig.4 Cross-sectional SEM images (a, b) of m-BN/PNF-50 nanocomposite paper; schematic diagram of thermal conduction for m-BN/PNF-50 nanocomposite paper in the in-plane (a′) and through-plane (b′) direction

Them-BN/PNF-50 nanocomposite paper is also used as the heat dissipation material in the lithium-ion rechargeable battery (Fig.S11).Figure 3d, d′ shows the curves of temperaturesvs.time for the bare lithium-ion rechargeable battery, the lithium-ion rechargeable battery integrated with PNF paper andm-BN/PNF-50 nanocomposite paper and the corresponding infrared thermal images.When the lithiumion rechargeable battery starts to work, the temperature of the core components increases gradually, among which the bare core components show the highest heating rate, and that of them-BN/PNF-50 nanocomposite paper shows the lowest.After charging for 150 s, the surface temperature of core components integrated withm-BN/PNF-50 nanocomposite paper stabilizes around 36.4 °C, significantly lower than the surface temperature of bare core component of 46.3 °C and core components integrated with PNF paper of 41.1 °C.This is mainly because them-BN/PNF-50 nanocomposite paper presents excellent heat dissipation property, which can quickly diffuse the heat from the lithium-ion rechargeable battery.Therefore, them-BN/PNF-50 nanocomposite paper is an efficient kind of thermal management material with broad application prospects in lithium batteries and integrated circuits.

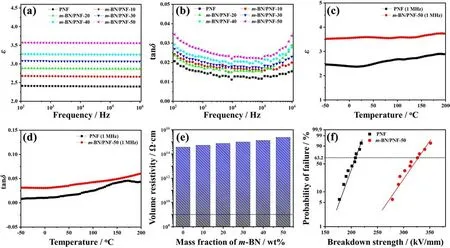

Fig.5 ε (a) and tanδ (b) of m-BN/PNF nanocomposite paper at different frequencies; ε (c) and tanδ (d) of PNF paper and m-BN/PNF-50 nanocomposite paper in the range of - 50 to 200 °C; volume resistivity (e) of m-BN/PNF nanocomposite paper; Weibull plots for breakdown strength(f) of PNF paper and m-BN/PNF-50 nanocomposite paper

Figure 3e shows TGA curves of PNF paper andm-BN/PNF-50 nanocomposite paper.PNF paper andm-BN/PNF-50 nanocomposite paper exhibit excellent heat resistances,andm-BN/PNF-50 nanocomposite paper has only slight weight loss below 640 °C, attributed to the degradation of benzidine.When the temperature is higher than 640 °C, the weight of PNF paper andm-BN/PNF-50 nanocomposite paper begins to decrease significantly, mainly attributed to the carbonization of PBO molecular chains.Figure 3f–i shows optical photographs of PNF paper (f) andm-BN/PNF-50 nanocomposite paper (g) before and during burning, SEM images of PNF paper (h) andm-BN/PNF-50 nanocomposite paper (i) after burning, respectively.PNF paper andm-BN/PNF-50 nanocomposite paper only shrink and curl slightly when they stay on the flame for 10 s.After removing the flame (> 20 s), no obvious flame and smoke are observed on PNF paper andm-BN/PNF-50 nanocomposite paper, and they basically maintain the original shape.From Fig.3h, i,PNF paper andm-BN/PNF-50 nanocomposite paper form a dense carbon layer on the surface after burning, which can prevent oxygen from entering the interior [61, 62], showing that PNF paper andm-BN/PNF-50 nanocomposite paper both have excellent flame-retardant properties.To further evaluate the flame-retardant properties of PNF paper andm-BN/PNF-50 nanocomposite paper, The microscale combustion calorimetry is used to quantificationally measure the heat release rate of PNF paper andm-BN/PNF-50 nanocomposite paper (Fig.S12).Them-BN/PNF-50 nanocomposite paper exhibits the low peak heat release rate of 154.3 W g-1,lower than that of the PNF paper (221.4 W g-1).Results suggest that the introduction ofm-BN further improves the flame-retardant property ofm-BN/PNF-50 nanocomposite paper.The reason is thatm-BN presents extremely excellent thermal stability (Fig.S7c) and can be used as a flame retardant to prevent the spread of flame, thereby improving the flame-retardant property.

3.3 Electrical Insulation of m-BN/PNF Nanocomposite Paper

Figure 5a, b shows the dielectric constant (ε) and dielectric loss tangent (tanδ) ofm-BN/PNF nanocomposite paper at different frequency.At the same frequency,εand tanδofm-BN/PNF nanocomposite paper gradually increase with the increasing amount ofm-BN.When the mass fraction ofm-BN is 50 wt%, theεand tanδofm-BN/PNF-50 nanocomposite paper are 3.55 and 0.033 (1 MHz), higher than that (εof 2.39 and tanδof 0.015, 1 MHz) of PNF paper, but lower than that (εof 3.76 and tanδof 0.042, 1 MHz, Fig.S13) of BN/PNF-50 nanocomposite paper.This is because BN with highε(~ 4.0) increases theεof the nanocomposite paper.In addition, the introduction ofm-BN or BN produces new interfaces with PNF.Under the action of applied electric field, charge carriers accumulate on the interface and induce interfacial polarization, which further increases theεand tanδ.Compared with BN/PNF nanocomposite paper,m-BN forms strong hydrogen bond and π–π interaction with PNF,which would reduce the interfacial polarization, resulting in relatively lowerεand tanδofm-BN/PNF nanocomposite paper.

In addition, theε(3.55–3.59) and tanδ(0.021–0.033) ofm-BN/PNF-50 nanocomposite paper show no significant changes in the range of 100 Hz–1 MHz, indicating excellent frequency stability.Figure 5c, d shows theεand tanδof PNF paper andm-BN/PNF-50 nanocomposite paper in the range of - 50 to 200 °C.Theεand tanδof PNF paper andm-BN/PNF-50 nanocomposite paper generally increase with increasing temperature.When the temperature rises from - 50 to 200 °C, theεofm-BN/PNF-50 nanocomposite paper increases from 3.51 to 3.73, showing an increase of 0.22, lower than the increase (0.43) of PNF paper.The tanδincreases from 0.031 to 0.059, showing an increase of 0.028, lower than the increase (0.035) of PNF paper.The main reason is that, within a certain range, the increase of temperature is conducive to the orientation of molecular chains, promoting the generation of atomic and orientation polarization [63, 64], which leads to the increasingεand tanδof the PNF paper andm-BN/PNF nanocomposite paper.While BN presents excellent thermal stability, and its internal molecular structure is difficult to change in a wide temperature range, so that theεand tanδare less affected by temperature.Overall, the dielectric properties ofm-BN/PNF nanocomposite paper exhibit better temperature stability than that of PNF paper.

Figure 5e shows volume resistivity ofm-BN/PNF nanocomposite paper.Volume resistivity ofm-BN/PNF nanocomposite paper increases with the increasing amount ofm-BN.Them-BN/PNF-50 nanocomposite paper has the highest volume resistivity of 2.3 × 1015Ω cm, higher than that of the PNF paper (3.6 × 1014Ω cm), which meets the requirements for the use of insulating materials inside electronic/electrical devices (> 109Ω cm) [65].To our satisfaction, them-BN/PNF-50 nanocomposite paper presents high breakdown strength (Fig.5f) of 324.2 kV mm-1.The excellent electrical insulation is attributed to the high volume resistivity (1016–1018Ω cm) ofm-BN, and charged carriers are difficult to carry out multiple migration betweenm-BN and PNF, promoting the high volume resistivity ofm-BN/PNF-50 nanocomposite paper.Under the action of applied voltage,m-BN can be used as the scattering point, and ejected electrons in the PNF matrix directly collide withm-BN and lose energy [66–68].Them-BN/PNF-50 nanocomposite paper requires higher voltage to achieve breakdown.

3.4 Mechanical Properties of m-BN/PNF Nanocomposite Paper

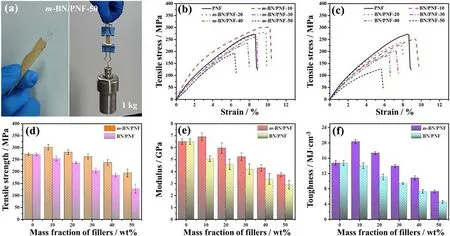

Figure 6a shows that them-BN/PNF-50 nanocomposite paper can be bent arbitrarily, and withstand a 1-kg reactor without any crack or fracture, indicating flexibility and robust mechanical properties.From Fig.6b, c, after linear elastic deformation and yielding, BN/PNF andm-BN/PNF nanocomposite paper undergoes obvious plastic elongation until fracture.Figure 6d–f shows tensile strength (d), tensile modulus (e) and toughness (f) of BN/PNF andm-BN/PNF nanocomposite paper.With the increasing amount ofm-BN and BN, the tensile strength, tensile modulus and toughness ofm-BN/PNF-50 nanocomposite paper increase first and then decrease, while the tensile strength, tensile modulus and toughness of BN/PNF-50 nanocomposite paper gradually decrease.Under the same amount ofm-BN and BN, the tensile strength, tensile modulus and toughness ofm-BN/PNF nanocomposite paper are all higher than those of the BN/PNF nanocomposite paper.When the mass fraction ofm-BN is 10 wt%, the tensile strength and modulus and toughness of them-BN/PNF-10 nanocomposite paper reach the maximum values of 301.5 MPa, 6.9 GPa and 20.3 MJ m-3, respectively, 10.8%, 6.2% and 38.1% higher than those of PNF paper, also higher than the tensile strength (254.6 MPa),tensile modulus (5.1 GPa) and toughness (14.0 MJ m-3) of BN/PNF-10 nanocomposite paper.When the mass fraction ofm-BN is 50 wt%, the tensile strength (193.6 MPa), tensile modulus (3.72 GPa) and toughness (7.26 MJ m-3) ofm-BN/PNF-50 nanocomposite paper are slightly lower than those of PNF paper.

The excellent mechanical properties are mainly attributed to the construction of extensive hydrogen bonds and π–π interactions betweenm-BN and PNF, and stable nacre-mimetic layered structures.The introduction of appropriate amount ofm-BN can effectively slow down the crack propagation and transfer stress and improve the mechanical properties ofm-BN/PNF nanocomposite paper.However, excessivem-BN tends to form stress concentration points in them-BN/PNF nanocomposite paper.In contrast, the relatively poor compatibility between BN and PNF leads to the formation of more defects and stress concentration points within the BN/PNF nanocomposite paper, resulting in the serious decline in mechanical properties.

Fig.6 Optical photographs of m-BN/PNF-50 nanocomposite paper possessing ultra-flexibility and withstanding a 1-kg reactor (a); tensile stress–strain curves of BN/PNF (b) and m-BN/PNF (c) nanocomposite paper; tensile strength (d), tensile modulus (e) and toughness (f) of BN/PNF and m-BN/PNF nanocomposite paper

As shown in Table S1,m-BN/PNF-50 nanocomposite paper presents optimal thermal stability (thermal decomposition temperature up to 640 °C) and excellent thermal conductivity among the reported electrically insulating paper.Meanwhile,m-BN/PNF nanocomposite paper has excellent mechanical properties and high breakdown strength, showing a broad application prospect in highend thermal management fields such as electronic devices and electrical equipment.

4 Conclusions

FTIR, XRD and TGA show that benzidine has been successfully grafted on the BN surface (m-BN).TEM and SEM indicate that PBO fibers are exfoliated into PNF,andm-BN and PNF have formed 3D crosslinked network structures.When the mass fraction ofm-BN is 50 wt%,m-BN/PNF-50 nanocomposite paper presents the highestλ//andλ⊥of 9.68 and 0.84 W m-1K-1, respectively, increased by 393% and 494% compared with the PNF paper.The nanocomposite paper also presents excellent electrical insulation (volume resistivity of about 2.3 × 1015Ω cm and breakdown strength of 324.2 kV mm-1), and its dielectric properties exhibit excellent frequency and temperature stability.In addition, the nanocomposite paper has excellent mechanical properties (tensile strength of 193.6 MPa),outstanding thermal stability (thermal decomposition temperature > 640 °C) and flame retardancy (self-extinguishing immediately after evacuation from the flame).

AcknowledgementsThe authors are grateful for the support and funding from the Foundation of National Natural Science Foundation of China (52373089 and 51973173), Startup Foundation of Chongqing Normal University (23XLB011), Science and Technology Research Program of Chongqing Municipal Education Commission (KJQN202300561), Fundamental Research Funds for the Central Universities.K.P.Ruan thanks for the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (CX2022073).

Declarations

Conflict of interestThe authors declare no interest conflict.They have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.Junwei Gu is an editorial board member for Nano-Micro Letters and was not involved in the editorial review or the decision to publish this article.All authors declare that there are no competing interests.

Open AccessThis article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing,adaptation, distribution and reproduction in any medium or format,as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material.If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.To view a copy of this licence, visit http:// creat iveco mmons.org/ licen ses/ by/4.0/.

Supplementary InformationThe online version contains supplementary material available at https:// doi.org/ 10.1007/s40820- 023- 01257-5.

- Nano-Micro Letters的其它文章

- Coaxial Wet Spinning of Boron Nitride Nanosheet-Based Composite Fibers with Enhanced Thermal Conductivity and Mechanical Strength

- Deep Insight of Design, Mechanism, and Cancer Theranostic Strategy of Nanozymes

- Internal Polarization Field Induced Hydroxyl Spillover Effect for Industrial Water Splitting Electrolyzers

- Exploring the Roles of Single Atom in Hydrogen Peroxide Photosynthesis

- Advances of Electrochemical and Electrochemiluminescent Sensors Based on Covalent Organic Frameworks

- MXene Enhanced 3D Needled Waste Denim Felt for High-Performance Flexible Supercapacitors