Investigation on Microcrystalline Wax Doped Asphalts by Temperature Control Mode of Atomic Force Microscopy

(School of Transportation, Southeast University, Nanjing 210096)

Investigation on Microcrystalline Wax Doped Asphalts by Temperature Control Mode of Atomic Force Microscopy

Yang Jun; Yao Zeheng; Gong Minghui; Yao Hongmiao

(School of Transportation, Southeast University, Nanjing 210096)

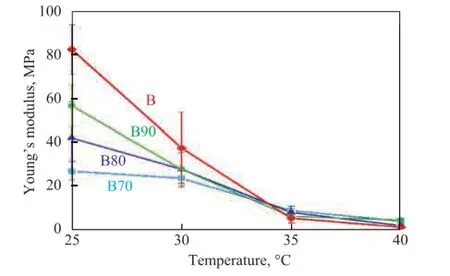

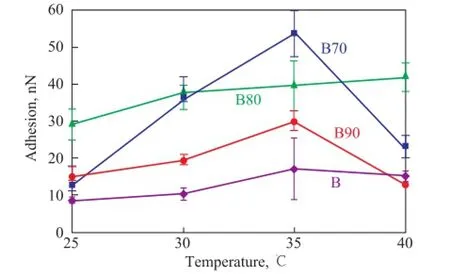

Because of its economical and environmentally friendly characteristics, the warm mix asphalt (WMA) is widely used in pavement engineering. However, the lack of microscopic study of WMA brings diffculties in understanding of its mechanical behavior and mechanisms at macroscopic scale which fnally hinders the enhancement of WMA’s performance. Therefore, this article aims to use atomic force microscopy (AFM), a promising microscopic technique, to investigate the effects of wax-based warm mix agents on asphalt microstructures and micromechanical properties at different temperatures. For simplicity’s sake, microcrystalline waxes are selected as an alternative of these wax-based additives. It is shown that the sample preparation method has a vital impact on the morphology of asphalt samples. The effects of microcrystalline wax on asphalt’s mechanical properties can be well captured by AFM tests. Results show that the blending of #70, #80 and #90 microcrystalline waxes lowers the modulus (20—60 MPa) of Pen70 asphalt at 25 ℃ while increasing its adhesion force (5—20 nN). The results of this study may shed some light on the comprehension of the effects of wax-based additives on asphalt materials at macroscopic level which can help estimate and predict its actual performance.

warm mix asphalt, micromorphology, micromechanical properties, microcrystalline wax

1 Introduction

Asphalt, a fnal residuum of crude oil distillation process, is widely used in paving and waterproof engineering. For many years, researchers have been making efforts to improve the mechanical properties and durability of asphalt materials, which can contributes to high quality pavements. In engineering fields, the warm mix asphalt (WMA) is one of the most widely used paving materials due to its economical and environmentally friendly characteristics. Warm mix asphalt is a special kind of asphalt which requires a lower mixing and construction temperatures. The relatively low construction temperature extends the construction seasons suitable for WMA application and reduces emissions and energy consumption[1]. Among several commercial warm mix agents, the wax-based additives (e.g. Sasobit) are the most frequently used. These wax-based organic warm-mix agents were found to have superior performance as compared with other warmmix agents. Research shows that WMA is likely to have reduced stiffness, loss of viscosity and increased susceptibility to permanent deformation due to the reduced temperature adopted during short-term aging. But Sasobit can compensate these demerits in performance[1]. Sasobit is also able to partly increase the nano-scale adhesive forces of asphalt binders[2]. Therefore, from the practical view, the effects of wax-based additives on asphalt properties deserve further investigation in order to optimize the design and construction stages of WMA pavements[3].

However, most of present studies still focus on the macroscopic effects of wax-based additives on asphalt (for example, effects on low temperature properties and aging performance of binders and mixtures)[1]. Few researches were performed regarding their microscopic properties. Actually, it has been long recognized that the microscopic behavior of a material is responsible for its macroscopic mechanical properties[4-5]. Knowledge at that level including the chemical composition, the microstructures and their interactions is pretty critical. It can help explore the fundamental mechanisms that guide the asphalt behavior at macroscopic level and will in turn help optimize its properties in production process[3]. However, as a com-plex mixture composed of different hydrocarbons, metal cations and other organic molecules, it is quite difficult to determine the specifc composition of asphalt derived from different crude sources at molecular scale as well as to fnd its relation to material performance. Therefore, effective new experimental technique is needed to help investigate asphalt materials and acquire aforementioned knowledge at microscopic level.

In recent years, the emergence of atomic force microscopy (AFM) in the asphalt research feld has provided a lot of meaningful achievements. Generally, the AFM setup uses a cantilever carrying a silicon carbide probe to contact the sample surface and records the displacement of the tip. After scanning over the sample surface, a highresolution image is captured which contains the topography data of the selected area on the sample surface. These images can help researchers identify the phases and microstructures of the sample surface[6]. Besides the imaging function, AFM can be used to obtain the micromechanical properties of samples by its force measurements technique[3]. For selected interaction sites, the force-distance data will be recorded while the probe contacts or indents into the sample surface. Micromechanical properties such as modulus and adhesion force can be calculated using corresponding mechanical models of the analysis software. These indexes can lead to a comprehensive understanding of the link between the micromechanical properties and the resulting mechanical behavior of the asphalt materials[7].

Research has indicated that microstructure observed by AFM is closely related to the microcrystalline wax in asphalt[3,8-9]. Thus, it is rational to deduce that AFM is a suitable method for research on wax-based warm mix asphalt. However, only a few work has been done to investigate the WMA or microcrystalline wax blended asphalt at different temperatures using AFM. The connections between WMA’s micro and macro properties have not been well established. Therefore, this study aims to use the temperature control mode of AFM to investigate the effects of wax-based additives on asphalt for better understanding of micro properties of WMA. For the sake of simplicity, this paper used microcrystalline waxes to represent the wax-based additives. In future study, practical WMA additives will be used and further compared with data in this paper to better understand their mechanism from mechanical and microstructure views.

2 Background

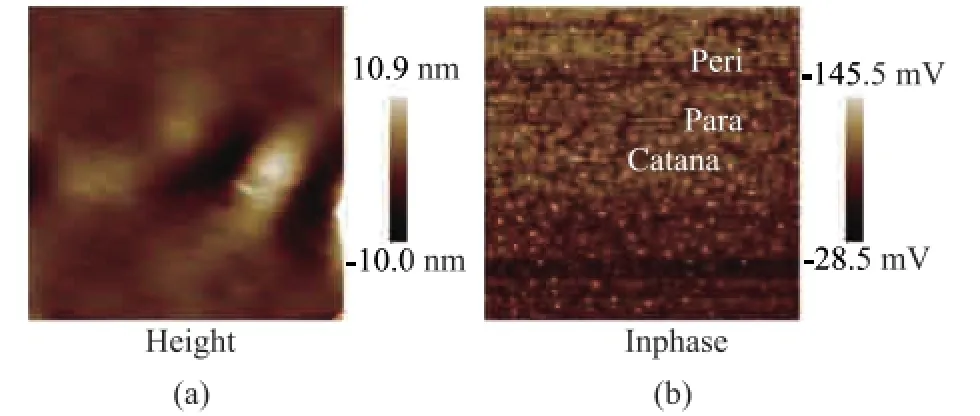

The presence of wax and its interaction with other components in asphalt are reported to be responsible for the formation of the unique microstructures on asphalt surface[8-9]. These unique structures which were frst observed by Loeber, et al., have elongated regions with a series of aligned protrusions and depressions[5,10], just like little bees. The close-up of its undulating topography is demonstrated in Figure 1(a). As shown in Figure 1(b), the images of the asphalt surface can be divided into three phases. The relatively dark region is called the para phase which can also be seen as a matrix phase or a solvent region, in which the peri phases and catana phases can be identifed. Catana phases, the so-called bee structures, are surrounded by the peri phases which seem to be suspended on the para phases with a height difference of a few nanometers.

Figure 1 AFM close-up topography image (a) and inphase image (b) of an asphalt sample

In the early 2000s, the formation of bee structures was attributed to asphaltene aggregation because some researchers reported upon seeing a corresponding increase in the density of bee-shaped microstructures when they were investigating different contents of asphaltene-doped asphalt samples[11-12]. However, some researchers found a poor correlation between the asphaltene aggregations and the bee-shaped structures[13]. Subsequently, de Moraes, et al. and Schmets, et al. reported that the bee structures might be related to the presence of wax and its crystallization[14-15]. In agreement with Moraes and Schmets, Pauli, et al. made a hypothesis that the interaction between waxes and the remaining asphalt fractions was responsible for much of the structuring[8]. Because they found bee-shaped structures in the ‘pure’ maltene phase which containedno asphaltenes, while the de-waxed asphalt fractions did not show any microstructures. Prabir, et al. drew similar conclusions using AFM and differential scanning calorimetry (DSC) tests[3]. Generally, although no agreement has been reached, it is certain that the presence of wax and its complex interaction with other components (co-precipitation or co-crystallization) can play vital roles in the formation of bee structures to greatly affect the micromorphology of asphalt.

Wax does have a great influence on the properties of asphalt including viscosity, stiffness and fracture resistance. Due to the presence of waxy asphalt, the asphalt mixtures display a higher fracture temperature[15]. And the content and molecular weight of wax can directly affect the dilatometric properties of asphalt binders[16]. Some researchers have proposed that the wax-induced phase separation on asphalt surface can result in microcracks due to the non-uniform stress distribution occurring in phase interfaces[15]. These micro-cracks may develop to macro-cracks and lead to a degradation of physical performance. However, Fazaeli, et al. found that wax in asphalts can serve as a green technology as an asphalt additive that lowers mixing and pavement construction temperatures[17]. Thus, a rational regulation should be worked out to help enjoy the advantages of wax based additives whithout compromising the low temperature performance of aspahlt.

AFM would probably be a feasible way to acquire microscopic information to deepen our understanding of wax’s influence on asphalt and ultimately promote the proper use of WMA in construction. Some researchers have made efforts to employ AFM to evaluate asphalt’s adhesion property and have already obtained some promising results[8,15-16]. However, the temperature-dependent properties of wax-blended asphalt or WMA at microscopic scale have seldom been studied. Hence, this article tentatively investigates three kinds of microcrystalline wax doped asphalts at different temperatures with the imaging and force measurement using the AFM techniques. The main objective is to acquire the topography images and micromechanical properties (modulus and adhesion force) of wax-doped asphalts and their evolution when temperature changes. These data will reveal the effects of microcrystalline wax on asphalt which may improve the understanding of the impact of wax-based additives on WMA and fnally give guidance on its design, production and construction process.

3 Experimental

3.1 Materials

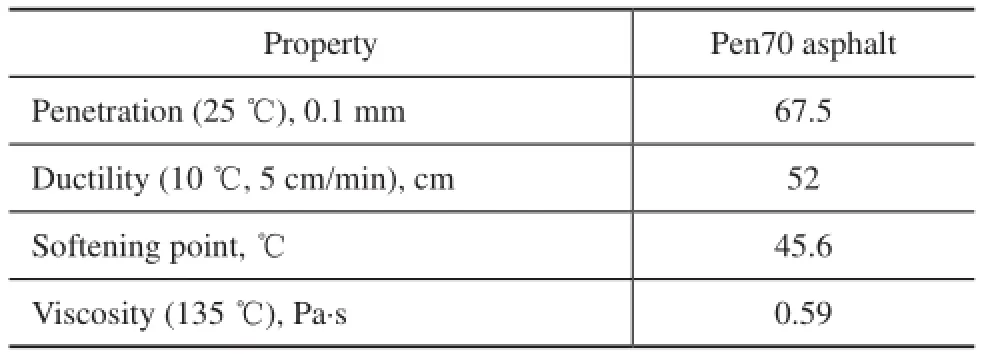

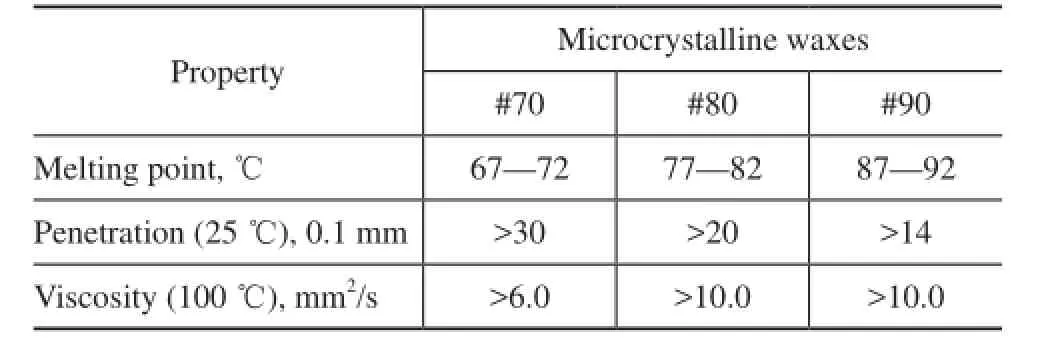

Pen70 (Penetration: 60—70 (0.1 mm)) asphalt (Baoli Asphalt Co.) and three kinds of microcrystalline waxes (Sinopec Group) were used in this study. The basic properties of Pen70 asphalt and microcrystalline waxes are illustrated in Table 1 and Table 2.

Table 1 Basic properties of Pen70 asphalt

Table 2 Basic properties of microcrystalline waxes

3.2 Sample preparation

3.2.1 Wax-doped asphalt

Three wax-doped asphalts were prepared by blending Pen70 asphalts with 1% of #70, #80 and #90 microcrystalline wax, respectively, using a high shear mixer (5 000 r/min, 140 ℃, 10 min) and were denoted as B70, B80, and B90, respectively. Pen70 was denoted as B.

3.2.1 AFM samples

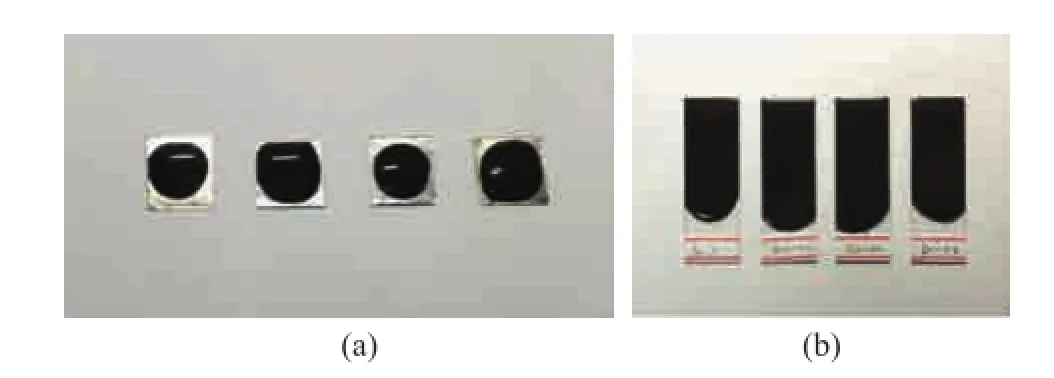

The AFM asphalt samples used in temperature control mode were made by coating liquid asphalt on the surface of small nickel sheets (approximately 8 mm×8 mm, as shown in Figure 2(a)) because of the limited size and magnetism of the heating stage of AFM. The wax-doped asphalts and Pen70 asphalt were heated to 140 ℃ and coated on the nickel sheets using a fne needle. Then the nickel sheet samples were kept at the same temperature for several seconds to allow the asphalt to spread out and createa relatively smooth surface. After being cooled down to room temperature, these samples were sealed up at ambient temperature for at least 24 h to stabilize their surface structures before being scanned.

Actually, the normal AFM samples are glass slide samples which are prepared using the same heat coating method mentioned above on glass slides. The glass slide samples are shown in Figure 2(b).

Figure 2 AFM samples: (a) nickel sheet samples; (b) glass slide samples

3.3 AFM observation

A Bruker AFM set-up (dimension icon) was used to scan all the samples. Being different from general AFM tests, the scan in temperature control mode used an independent system including a microscope, a silicon carbide probe, a temperature controller and a small heating stage (about 1 cm in diameter). The room temperature was 25 ℃. According to the softening point of Pen70 asphalt (45.6 ℃), all the samples were scanned at 25 ℃, 30 ℃, 35 ℃ and 40 ℃, respectively, to prevent the tip from the contamination by molten asphalt at over-temperature (>40 ℃). The scan area was 40×40 nm2. These samples were heated at a rate of 1 ℃/min and were held at the selected temperature for 3 min before being scanned. The tapping mode was chosen for the scan to reduce tip contamination and to improve scanning stability[18]. For each image, nine points (arranged in 3 rows and 3 columns from top to the bottom of the image) were selected to capture force-distance curves for further analysis of the sample’s micromechanical properties (modulus and adhesion force). The scanning frequency is 1 Hz and the cantilever has a nominal spring constant of 0.4 N/m and a nominal tip radius of 2 nm. The exact values of defection sensitivity and spring constant of the probe were calibrated through thermal tune method in spot tests[19]. The NanoScope Analysis 1.40 software was used for the fnal analysis of the topography images and force-distance curves.

3.4 Force curves analysis

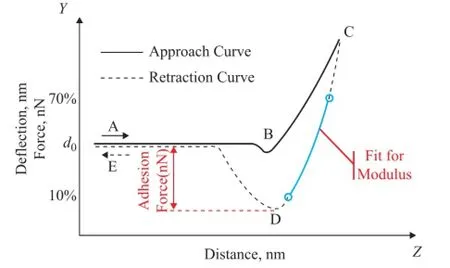

A typical force curve of asphalt binders is shown in Figure 3. The Y-axis shows the deflection of the cantilever from which the tip-sample interaction force can be calculated through the cantilever’s defection sensitivity. The X-axis represents the distance of the tip movement measured by height sensors.

Figure 3 A typical force curve of asphalt binders

Theoretically, the lowest point of the retraction trace of a force curve is the force required to pull the tip off the sample and hence is defined as the adhesion force[20]as demonstrated in Figure 3.

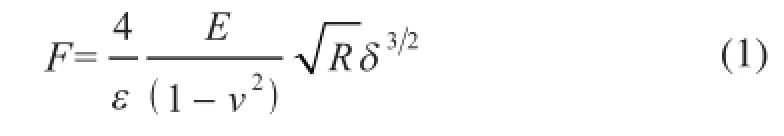

Generally, the slope of a force-distance curve describes the elastic properties of a sample and is often used to calculate the Young’s modulus. The modulus data of samples are calculated using the fit model in NanoScope Analysis 1.40 software. The fit model is Hertzian (Spherical) model where calculations are performed based on forces relative to the adhesion force instead of absolute force values. In other words, the adhesion of asphalt samples is considered. The model is defned as:

whereFis the interaction force between tip and the sample,Eandνis the Young’s modulus and Poisson ratio of the sample, respectively,Ris the radius of the tip andδis the indentation depth.

According to Hooke’s law, the forceFand the defection of the cantileverdare connected via the spring constantkof the cantilever[21]:

The equation (1) is applied to perform a nonlinear least squares ft to part of the retraction curve to calculate theYoung’s modulusE. In this article, the fit range is between 10% and 70% of the maximum force. The Poisson ratio is set to 0.3. The exact spring constantkand the radius of the tipRare calibrated through indentation tests on a standard sample.

4 Results

4.1 Morphology of asphalt surface

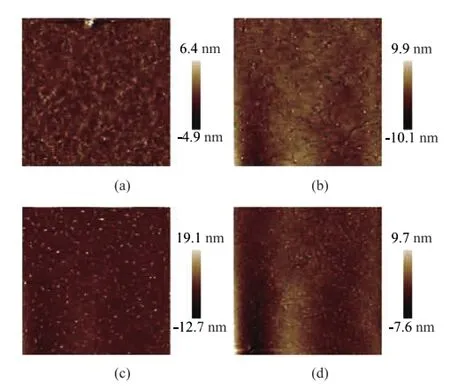

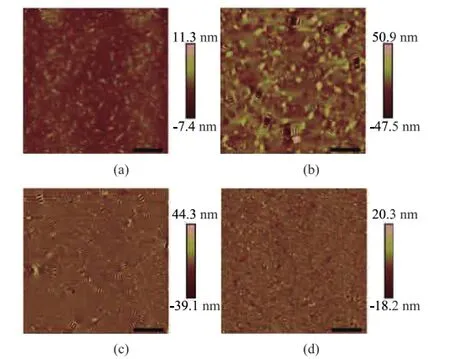

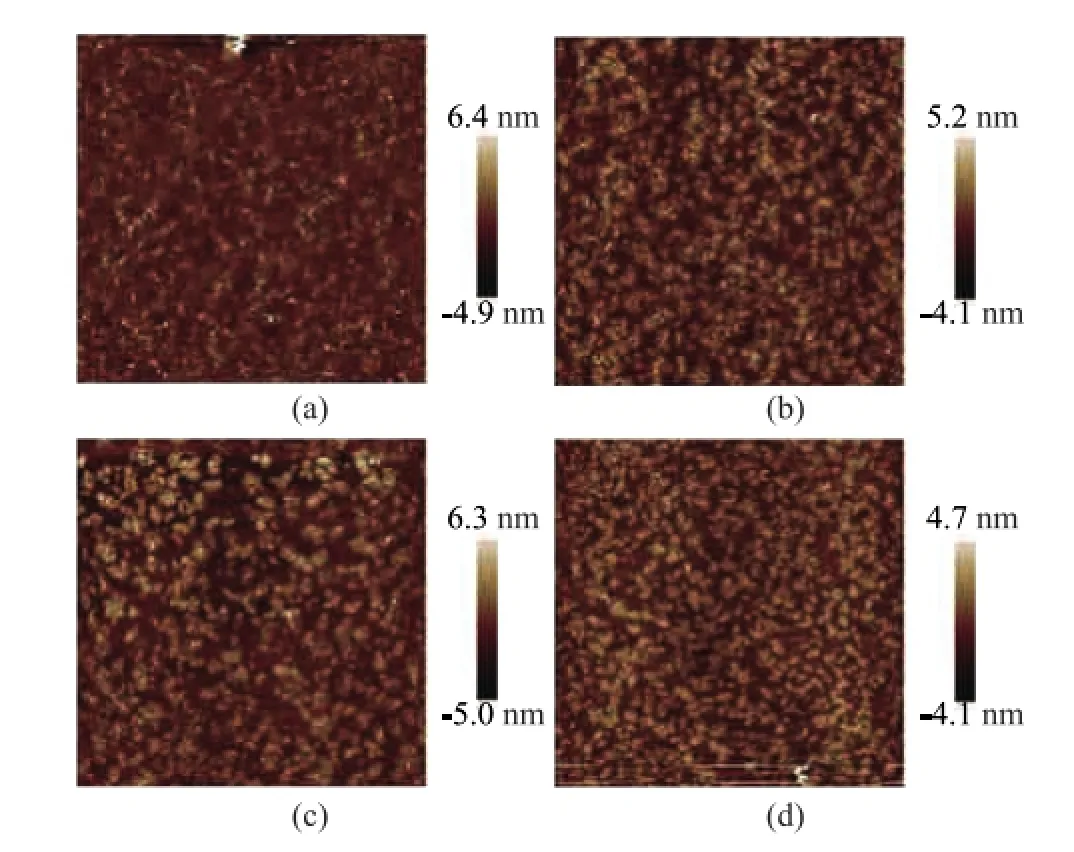

The 25 ℃ topography images of four asphalt samples are demonstrated in Figure 4. There are slight differences in surface micro-morphology (size and number of bee structures) of B, B70 and B80 while sample B90 has much smaller bee-shaped structures. However, in our previous research, the topographic images of the same four asphalt samples, which were coated on the glass slides, could be distinguished from each other remarkably (as shown in Figure 5). The bee structures of B70 and B80 (Figure 5(b) and (c)) are apparently larger in size than B (Figure 5(a)) while that of B90 is the smallest. It is concluded that different sample preparation methods will affect the surface morphology. Figure 5 indicates that the #70 and especially #80 microcrystalline wax may be able to promote the aggregation or formation of the bee-shaped microstructures on asphalt surface. The #90 wax, conversely, will impede the formation of bee structures when it is blended in the Pen70 asphalt, as shown in Figures 4 and 5.

Figure 4 Topographic images of B(a), B70(b), B80(c), B90(d) at 25 ℃

Compared with the AFM images of glass slide samples at 25 ℃ (Figure 5), the bee-shaped structures in Figure 4 are obviously smaller. This fact may be attributed to the aging of asphalt samples during the sample preparation process and/or different sample preparation methods[22]. Since the nickel sheet samples are tiny and the asphalt quantity on it is relatively low, it is much easier for sample to age under high temperature during sample preparation process. The radian of sample surface may also affect the images observed thereof. However, the evolution of bee structures with an increasing temperature and the mechanical properties measured are supposed to be unaffected. So it is suggested that the nickel sheet samples are reasonable in investigation of the thermal evolution of asphalt micromorphology as shown in this article. In order to observe the micro-morphology of asphalt samples at room temperature, the glass slide samples are more reasonable.

Figure 5 Topographic images of four glass slide samples: B(a), B70(b), B80(c), and B90(d)

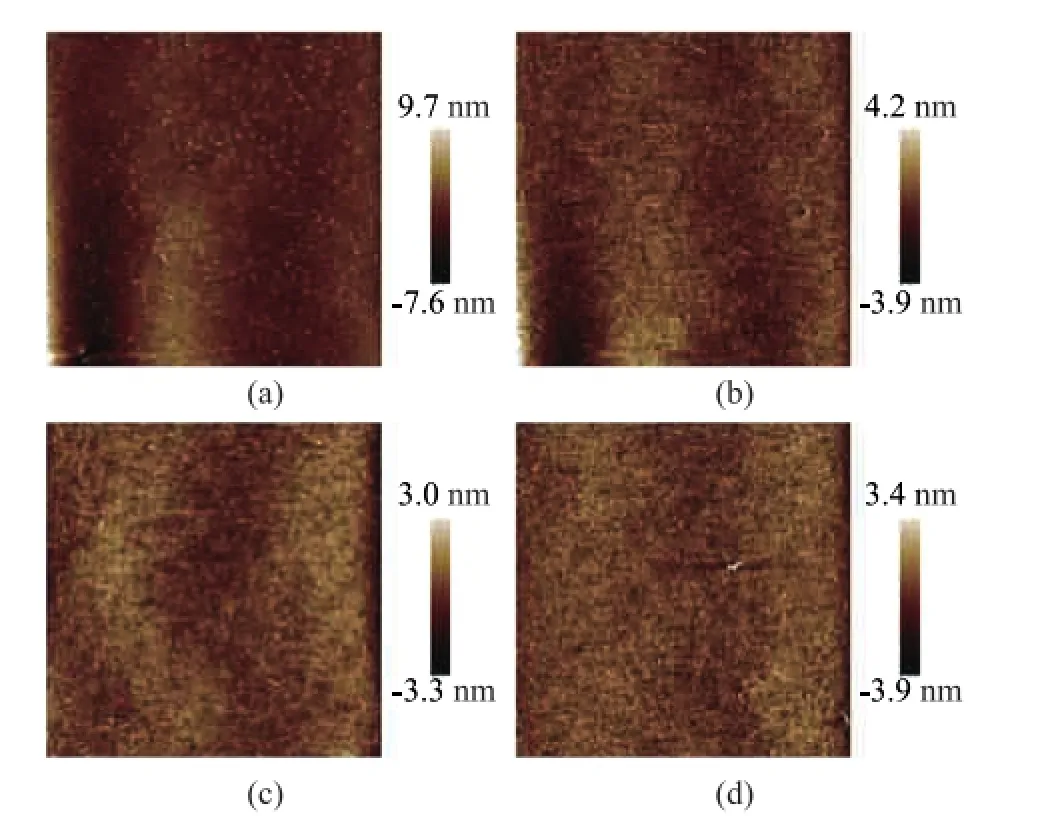

Figures 6, 7, 8 and 9 show the topographic images of B70, B80, B90 and B at different temperatures. As mentioned above, there are a large number of bee structures or catana phases dispersing in the Height/Topography images. But other two phases are not identifed.

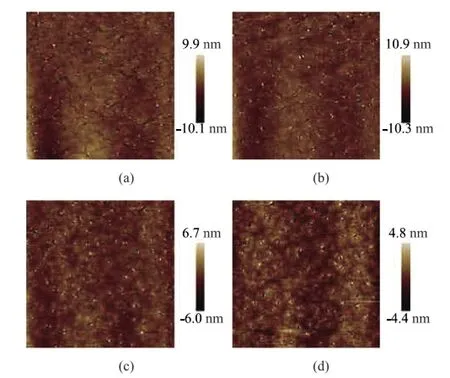

Figure 6 Topography images of B70 at: 25 ℃(a), 30 ℃(b), 35 ℃(c) and 40 ℃(d)

Asphalt B70 (Pen70 asphalt +1% of microcrystalline wax) is studied to investigate the evolution of surface micro-morphology with an increasing temperature (Figure 6(a)—(d)). It can be seen that the bee structures become fewer in number but a little larger in size when temperature increases from 25 ℃ to 40 ℃. It seems that small ‘bees’melt gradually and tend to assemble together. As the temperature keeps rising, these microstructures begin to vanish, which becomes especially obvious at the bottom of Figure 6(c) and 6(d) and the topographic images turn relatively flatter (which can be inferred from roughness data in the latter part). Images of B, B80 and B90 show similar process of the surface micro-morphology as temperature goes up and the bee structures in Figure 8(d) and 9(d) even completely disappear. It is speculated that the number of bee structures tends to decrease when the temperature increases. This phenomenon may be attributed to the melting of microcrystalline wax in ‘bees’.

Figure 7 Topographic images of B80 at: 25 ℃(a), 30 ℃(b), 35 ℃(c) and 40 ℃(d)

As regards the sample B80, there are almost negligible changes (Figure 7(a)—(d)). It is until 40 ℃ that the microstructures turn to be a little sparse. At 40 ℃, the bee structures do not vanish as compared to those in B70 images. This phenomenon may be attributed to the increase of its melting point. It is supposed that the melting point of microcrystalline waxes blended in B70 and B80 samples (Table 2) are higher than that in neat asphalt (usually at a temperature of lower than 60 ℃) so that they can increase the melting temperature of surface bee structures. The melting point of #80 wax is higher than that of #70, and the process mentioned above is much slower. Another reason for the negligible changes of topographic images may be the relatively short duration of the heating process.

Figure 8 Topographic images of B90 at: 25 ℃(a), 30 ℃(b), 35 ℃(c) and 40 ℃(d)

According to Moraes, these white spots in Figure 8(c)—(d) might be insoluble components in matrix phase (crystalline asphaltenes or wax) and could be the nucleation centers during the crystallization of bee structures when the asphalt samples was subject to annealing[14,23].

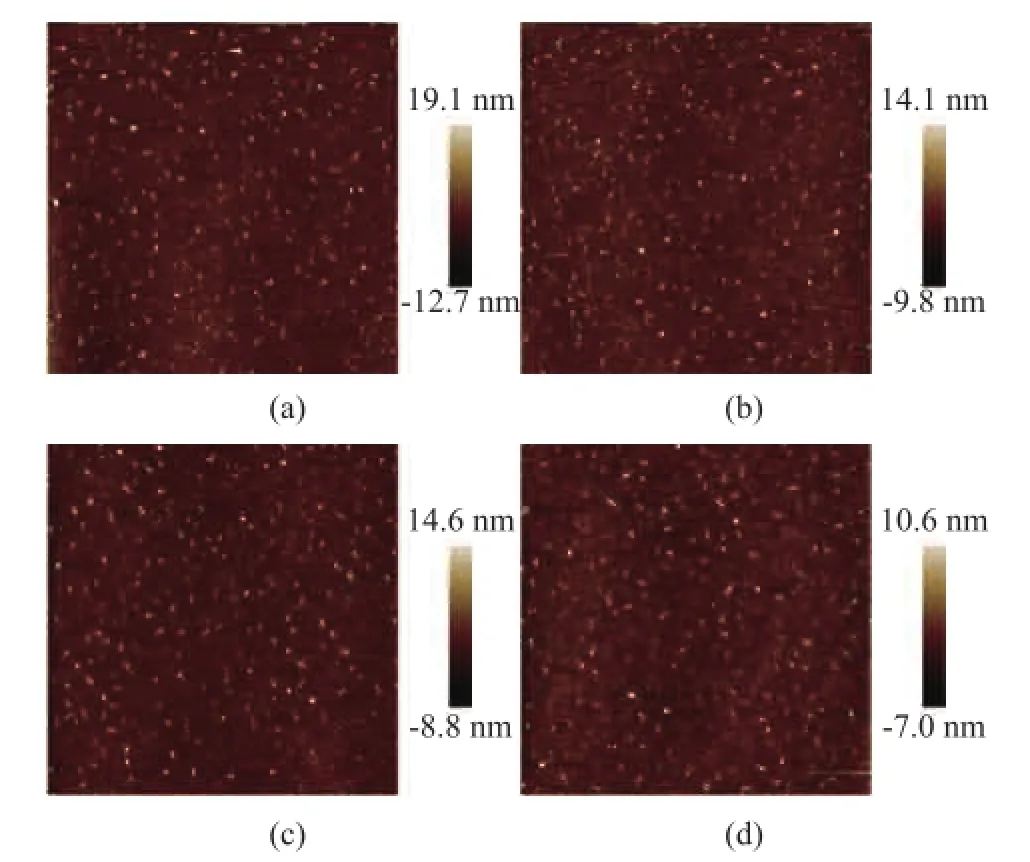

Figure 9 (a)—(d) shows a relatively complete process of the melting of bee structures. And the peri and para phases are very clear. Then the asphalt B was annealed at room temperature for 1 h. The topographic image of B after annealing is demonstrated in Figure 10. It can be found out that the ‘bees’ in Figure 10 are smaller and fewer as compared with Figure 9(a). It may be attributed to the unstable surface micro-morphology upon cooling and ageing of samples after a thermal cycle.

Figure 9 Topographic images of B at: 25 ℃(a), 30 ℃(b), 35 ℃(c) and 40 ℃(d)

Figure 10 Topographic image of B after annealing to 25 ℃

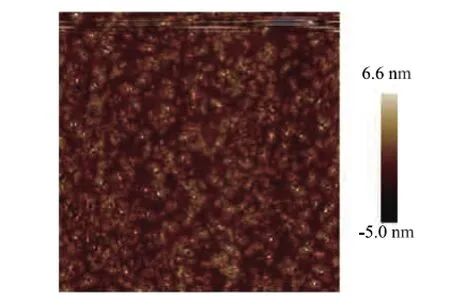

4.2 Roughness

Roughness data can be calculated from the topographic images. It is the average altitude of a specifc area in topographic image which can refect the number of bee structures and the height of their undulate topography. Figure 11 lists the roughness data of topographic images of four samples. In general, the roughness data all show a decline trend except that of B, which corresponds to the melting of surface microstructures. And the roughness data of B70 and B80 are much higher than that of B which illustrates the promoting effects of microcrystalline wax in formation of ‘bees’. The out-of-order data (for example, B70 at 25 ℃ and B at 35 ℃) may be attributed to the scanning scratches.

4.3 Mechanical properties

Figure 11 Surface roughness data of four asphalt samples

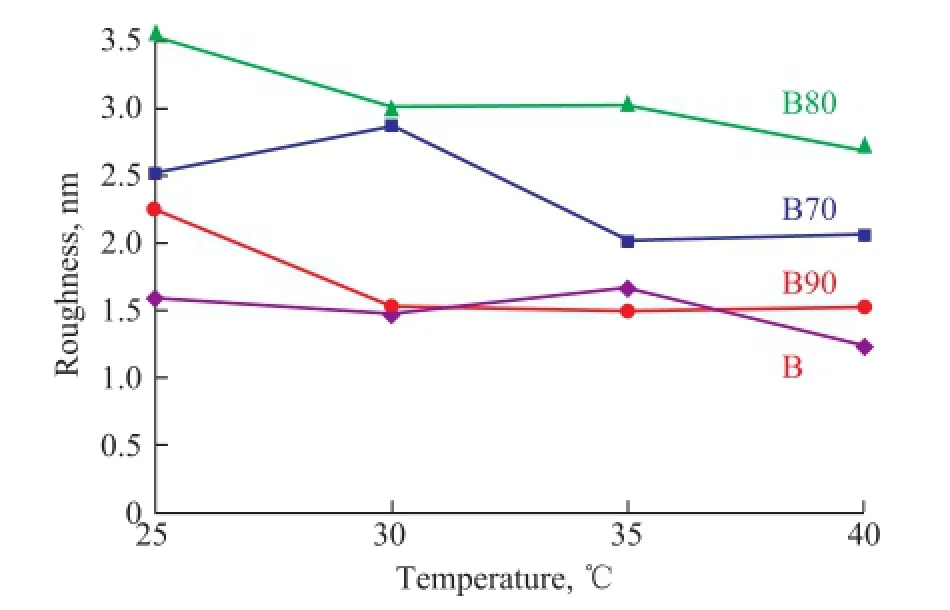

After the scanning processes, nine points (3 rows and 3 columns from top to the bottom of the image) were selected in each topographic image to perform indentation tests to study the micromechanical properties of asphalt samples. A force-distance curve can be captured from each point with which Young’s modulus and adhesion force data can be calculated using the NanaScope Analysis 1.40 software. Four representative force curves of four samples in this study are demonstrated in Figure 12 in a bid to give an intuitive sketch and comparison. As data are calculated by specifc computational models, these numbers may not be absolutely true values, but the qualitative comparison between them does reveal the useful information and general rules about micromechanical characteristics of asphalt samples. Moreover, these temperature-dependent micromechanical data are also critical input parameters of some finite element models in predicting asphalt performance and can qualitatively refect some macroscopic properties (modulus and viscosity) of these asphalt samples.

4.3.1 Young’s modulus

The Young’s modulus data of four samples at different temperatures are presented in Figure 13.

Figure 12 Typical force curves of four asphalt samples

It is revealed in Figure 13 that asphalt B has a highestYoung’s modulus of 82.35 MPa at 25 ℃. At the same temperature, the asphalt surface modulus decreases after the blending of microcrystalline wax. B70 has the lowest modulus (27.08 MPa) because the wax is relatively softer than asphalt and the #70 wax is the softest crystalline wax according to the penetration data in Table 2. Figure 13 clearly shows that the modulus data of four samples all undergo a dramatic drop with a rising temperature. The asphalt B shows a sharpest decline which indicates that the asphalt B has the highest temperature sensitivity in modulus among these four asphalt samples.

Figure 13 Line graph of Young’s modulus data of four samples

4.3.2 Adhesion force

The adhesion force data are shown in Figure 12. These data represent the adhesion force measured between the tip and the sample surface. Some research utilizes this data to simulate the adhesive force between asphalt and aggregates to predict the actual performance of asphalt mixtures or to help build computational models.

Figure 14 Line graph of adhesion data of four samples

According to Figure 14, the adhesion force of asphalt samples B, B70 and B90 increases with a rising temperature except the case at 40 ℃. It indicates that the adhesion force between asphalt and aggregates in asphalt mixtures will increase as temperature rises in the range between 25 ℃and 35 ℃. In addition, the adding of microcrystalline wax does increase the adhesion data of asphalt samples. The adhesion force of B80 is higher than B70 at 25 ℃. However, as the temperature keeps rising, the adhesion force of B70 goes higher than that of B80. This may occur owing to the slow melting process of B80 so that its adhesion still keeps growing. It is supposed that the melting phenomenon of bee structures can correlate with changes in adhesion force. The adhesion force of B90 is relatively low and even lower than that of B as temperature increases. This phenomenon can be associated with the aforementioned immiscibility between the #90 microcrystalline wax and Pen70 asphalt, which may be ascribed to their different components and molecular structures. The adhesion force of B after annealing to 25 ℃ decreases to 6.15 nN, which may be attributed to the reorganization of microstructures. It is supposed that the surface of asphalt samples B, B70 and B90 may be in a nearly molten state and hence can lose their most adhesion force at 40 ℃.

According to the micromechanical data mentioned above, the asphalt B70 is supposed to be the asphalt with low elasticity but highly temperature-sensitive adhesion, while the asphalt B shows low adhesion and high modulus, especially at low temperature. The asphalt samples B80 and B90, correspondingly, fall in between these asphalt samples B and B70.

In addition, due to the difference of topography and micromechanical data of asphalt B before and after heating, it is inferred that its micro-morphology and micromechanical properties depend largely on its thermal history.

5 Discussion

This study has investigated the micro-morphology and micromechanical properties of four asphalt samples at different temperatures. These samples, including a neat asphalt and three kinds of microcrystalline wax doped asphalts, were prepared to investigate the impact of wax on the microstructures and mechanical properties of asphalt which may shed some light on the effects of wax-based warm-mix agents in WMA.

The results of this study indicate that different microcrys-talline waxes have different effects on asphalt microstructures and microscopic properties (e. g. melting points, modulus and adhesion). Generally, the blending of waxbased additives in WMA will enhance the adhesion along with reducing the modulus of asphalt, besides lowering its mixing and construction temperature. These additives will increase the adhesion force of the asphalt which will in turn enhance the bonding between asphalt binders and aggregates. It is inferred that, Sasobit, the widely used waxbased additive in WMA, may have similar compositions with the #90 wax. This may help to better understand the mechanism of Sasobit related modifcation. The results of this study can lead to a better understanding of the effects of wax-based additives on asphalt properties which will fnally help optimize the WMA in its design and construction processes, including the proper choice of wax-based additives in actual engineering. Moreover, all these effects can be captured by AFM in topography images and force curves. It indicates that AFM can be a powerful technique to investigate the wax-based additives and the warm-mix asphalts at microscopic level.

Experimental results obtained in the last selection indicate that the evolution of topographic images and the changes of Young’s modulus and adhesion data nearly happened at the same time with an increasing temperature. In this way, the surface microstructures may help qualitatively estimate or predict the macroscopic performance of asphalt and asphalt mixtures. For example, asphalt with large and dense bee-shaped structures may exhibit high adhesion and high melting temperature. But its stiffness and modulus may be relatively lower due to the presence of substantial waxes. Further research should be performed to improve the understanding of the relation between microscopic and macroscopic properties which will fnally help optimize the WMA in practical engineering.

6 Conclusions

The AFM studies were performed to investigate the effects of microcrystalline waxes on the surface micro-morphology and micromechanical properties of asphalt with increasing temperature. Results would provide a theoretical foundation for future WMA study. Conclusions are as follows:

(1) Different methods of sample preparation will affect the surface morphology images.

(2) Generally, blending of the wax-based additives in asphalt can enhance the adhesion while lowering the modulus of asphalt.

(3) The bee structures tend to decrease in number with an increasing temperature and will reappear upon being cooled down, which can be attributed to the melting and crystallization of microcrystalline wax. The melting process is strongly dependent on the properties of microcrystalline wax.

(4) The evolution of micro-morphology and the changes of Young’s modulus and adhesion data of asphalt samples nearly happen at the same time so that the micromorphology data can help estimate and predict the bulk properties of asphalt.

(5) The surface Young’s modulus decreases and the adhesion force of asphalt increases with a rising temperature. And the micro-morphology and micromechanical properties of surface microstructures depend largely on the thermal history of samples.

(6) AFM has the potential to investigate wax-based additives and warm-mix asphalts at microscopic level.

However, further work is still required. For example, the maximum temperature limit is set at 40 ℃ to prevent the probe from the contamination of molten asphalt and the duration of heating process might be too short (3 min), leading to insignifcant changes of topographic images. A complete heating and cooling cycle should be performed to show the melting and formation of bee structures in detail to improve the understanding of its formation mechanism and the roles the microcrystalline wax plays. Further research should be performed to explore the relationship between the components of microcrystalline wax and its infuence on asphalt properties to better describe the effects of wax-based additives on WMA. Besides that, the functions of other components in wax-based additives should be investigated using AFM.

Acknowledgements: The authors gratefully acknowledge the fnancial support of the Education Department of Jiangsu Province under Grant No. JZ-007 and of the Jiangsu Natural Science Foundation under Grant No. BK 20140111.

[1] Arega Z, Bhasin A, Motamed A, et al. Infuence of Warm-Mix Additives and Reduced Aging on the Rheology of Asphalt Binders with Different Natural Wax Contents[J]. Journal of Materials in Civil Engineering, 2014, 23(10): 1453-1459

[2] Nazzal M D, Qtaish L A. The Use of Atomic Force Microscopy to Evaluate Warm Mix Asphalt. Final Report, FHWA/ OH-2012/19, Microscopy, 2013

[3] Das P K, Kringos N, Wallqvist V, et al. Micromechanical investigation of phase separation in asphalt by combining atomic force microscopy with differential scanning calorimetry results[J]. Road Materials & Pavement Design, 2013, 14(2): 25-37

[4] Lesueur D, Gerard J, Claudy P, et al. A Structure Model to Describe Asphalt Linear Viscoelasticity[J]. Journal of Rheology, 1996, 40(5): 813-836

[5] Loeber L, Muller G, Morel J, et al. Asphalt in colloid science: A chemical, structural and rheological approach[J]. Fuel, 1998, 77(13): 1443-1450

[6] Yang J, Wang X, Gong M, et al. Analysis of microscopic images of asphalt getting from atomic force microscopy[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2015, 31(5): 1110-1115

[7] Jahangir R, Little D, Bhasin A. Evolution of asphalt binder microstructure due to tensile loading determined using AFM and image analysis techniques[J]. International Journal of Pavement Engineering, 2015, 16(4): 337-349

[8] Pauli A T, Grimes R W, Beemer A G, et al. Morphology of asphalts, asphalt fractions and model wax-doped asphalts studied by atomic force microscopy[J]. International Journal of Pavement Engineering, 2011, 12(4): 291-309

[9] Yang J, Gong M, Pauli A T, et al. Study on microstructures of asphalt by using atomic force microscope[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2015, 31 (4): 959-965

[10] Loeber L, Sutton O, Morel J, et al. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy[J]. Journal of Microscopy, 1996, 182(1): 32–39

[11] Pauli A T, Branthaver J F, Robertson R E, et al. Atomic force microscopy investigation of SHRP asphalts[J]. American Chemical Society, Division of Petroleum Chemistry, Preprints, 2001, 46(2): 110-114

[12] J?ger A, Lackner R, Eisenmenger-Sittner Ch, et al. Identifcation of four material phases in bitumen by atomic force microscopy[J]. Road Materials and Pavement Design, 2004, 5, 9–24

[13] Masson J F, Leblond V, Margeson J. Asphalt morphologies by phase-detection atomic force microscopy[J]. Journal of Microscopy, 2006, 221(1): 17–29

[14] Moraes M B D, Pereira R B, Sim?o R A, et al. High temperature AFM study of CAP 30/45 pen grade asphalt[J]. Journal of Microscopy, 2010, 239(1): 46–53

[15] Schmets A, Kringos N, Pauli T, et al. On the existence of wax-induced phase separation in asphalt[J]. International Journal of Pavement Engineering, 2010, 11(6): 555-563

[16] Pauli T, Grimes W, Beiswenger J, et al. Surface Structuring of Wax in Complex Media[J]. Journal of Materials in Civil Engineering, 2014,27(8), C4014001:1-9

[17] Fazaeli H, Behbahani H, Amini A A, et al. High and Low Temperature Properties of FT-Paraffin-Modified Asphalt[J]. Advances in Materials Science & Engineering, 2012, vol. 2012, Article ID 406791, 7 pages, doi:10.1155/2012/406791

[18] Hung A M. AFM study of asphalt binder “bee” structures: origin, mechanical fracture, topological evolution, and experimental artifacts[J]. RSC Advances, 2015, 5(117): 96972-96982

[19] Sader J E, Chon J W M, Mulvaney P. Calibration of Rectangular Atomic Force Microscope Cantilevers[J]. Review of Scientifc Instruments, 1999, 70(10): 3967-3969

[20] Yu X, Burnham N A, Mallick R B, et al. A systematic AFM-based method to measure adhesion differences between micron-sized domains in asphalt binders[J]. Fuel, 2013, 113(9): 443-447

[21] Domke J, Radmacher M. Measuring the elastic properties of thin polymer flms with the atomic force microscope[J]. Langmuir, 1998, 14(12): 3320-3325

[22] Yang J, Gong M, Wang X, et al. Observation and characterization of asphalt microstructures by atomic force microscope[J]. Journal of Southeast University, 2014, 30 (3): 353-357

[23] Nahar S N, Schmets A J M, Scarpas A, et al. Temperature and thermal history dependence of the microstructure in bituminous materials[J]. European Polymer Journal, 2013, 49(8): 1964-1974

Received date: 2016-06-24; Accepted date: 2016-09-13.

Professor YangJun, Telphone: +86-25-83794069; Fax: +86-25-83794069; E-mail: yangjun@seu.edu.cn.

- 中國煉油與石油化工的其它文章

- Methodology for Design of Reactive Distillation Column and Kinetics for Isoamylene Etheri fi cation Catalysed by Amberlyst 35

- Optimization and Control of Extractive Distillation with Heat Integration for Separating Benzene/Cyclohexane Mixtures

- Molecular Simulation of Adsorption of Quinoline Homologues on FAU Zeolite

- Study on the Effect of Surface Modi fi cation on the Properties of Bentonite Greases

- Improvement of Magnetic Field on Tribological Properties of Lubricating Oils with Zinc Butyloctyldithiophosphate

- Study on Tribology Performance of Different Lubricant Additives under Atmospheric Pressure and High Vacuum Conditions