Why a mosquito leg possesses superior load-bearing capacity on water:Experimentals

Xiang-Qing Kong·Jian-Lin Liu·Cheng-Wei Wu

?

Why a mosquito leg possesses superior load-bearing capacity on water:Experimentals

Xiang-Qing Kong1·Jian-Lin Liu2·Cheng-Wei Wu3

?The Chinese Society of Theoretical and Applied Mechanics;Institute of Mechanics,Chinese Academy of Sciences and Springer-Verlag Berlin Heidelberg 2015

AbstractMosquitoes possess the striking ability to walk onwaterbecauseeachoftheirlegshasahugewatersupporting force(WSF)that is 23 times their body weight.Aiming at a full understanding of the origins of this extremely large force,in this study,we concentrate on two aspects of it:the intrinsicpropertiesofthelegsurfaceandtheactivecontrolof the initial stepping angle of the whole leg.Using a measurement system that we developed ourselves,the WSFs for the original leg samples are compared with those whose surface wax and microstructures have been removed and with those of a different stiffness.The results show that leg fl xibility plays a dominant role over surface wax and microstructures onthelegsurfaceincreatingthesupportingforce.Moreover, we discuss the dependence relationship between the maximumWSFandtheinitialsteppingangle,whichindicatesthat the mosquito can regulate this angle to increase or decrease theWSFduringlandingortakeoff.Thesefinding arehelpful for uncovering the locomotion mechanism of aquatic insects and for providing inspiration for the design of microfluids miniature boats,biomimetic robots,and microsensors.

KeywordsWater supporting force·Wax coating·Surface microstructures·Flexibility·Initial stepping angle

1 Introduction

Arthropods like fishe spiders and water striders have a remarkableload-bearingcapacityonwatersurfaces;theycan stand effortlessly and walk freely on ponds,rivers,and even oceans[1-3].Gao and Jiang[4]found that a single leg of a water strider can create a supporting force on water that is around15timesitstotalbodyweight.Obviously,thisstriking water-walking behavior holds great potential in a wide range of applications,including the design of miniature aquatic devices and the fabrication of nonwetting materials[5].

A great deal of attention has focused in recent decades on the locomotion mechanism of the water strider,and much effort has been devoted to researching this hot topic.The superior load-bearing capability of the water strider lies in thecapillaryeffect,i.e.,eachlegtreadsadimplearisingfrom surface tension,which can cause an additional buoyant force to sustain the water strider’s body[6-9].In addition,it was discovered through scanning electron microscopy that there are many oriented tiny hairs with fin nanogrooves distributed on the strider’s leg surface[4,7].The combination of this hierarchical structure and the secreted cuticle wax coating on the leg surface can lead to the superhydrophobicity of theleg,renderingacontactangleupto168?[7].Moreover,it was pointed out by Liu et al.[9]that both the hollow annular cross-sectionalshapeofthestriderlegandtheself-adaptation of its surface setae to water enhance its water supporting force(WSF).In addition to these factors,the deformation of the whole leg during contact with water makes a nonnegligible contribution to this supporting force.For example, the important role of the fl x rotation of the water strider when its leg presses on a water surface has been stressed by Zheng et al.[10].Additionally,several continuum mechanics models have been developed on slender rods or sheetscoupled with a liquid-vapor interface,indicating that a fl xible body produces a greater buoyant force than a rigid body, which provides a theoretical explanation for strider locomotion[11-14].

Although the water strider has generated tremendous enthusiasminthescientifi community,tosomeextent,there is a lack of keen interest in the mosquito,which possesses an even greater load-bearing capability than the strider.For instance,it has been reported that a single hind leg of a mosquito can endure a supporting force on water of 600μN(yùn), which is equal to 23 times the mosquito’s body weight[15]. This striking load-bearing capability has commonly been ascribed to the hierarchical micro-/nanostructures on the leg surface,which can result in a large contact angle of around 153?[15].However,this issue has not been settled,with some researchers claiming that the rough structures on the leg are not as important as has been imagined.As an example of the water strider leg,Vella asserted that the variation in the apparent contact angle from 100?to 167?with different microstructures has little effect on the maximum WSF [13].Apart from the surface microstructures,other factors, such as the secreted wax,fl xibility,and contact posture of the leg,should be comprehensively considered.Therefore, we carried out a series of experiments aiming at a full understanding of how these factors quantitatively affect the WSF of the mosquito leg.

Thisarticleisorganizedasfollows.InSect.2,thesetupof themeasurementsystemdevelopedbyusfortestingtheWSF is introduced.In Sect.3,the roles of the intrinsic properties of the leg surface in producing the WSF are discussed.First, the WSFs for the original leg samples are compared with those on which the surface wax and microstructures were removed.Next,the effect of a leg’s fl xibility on its WSF is presented,and a comparison is made with an artificia leg madeofsteel.InSect.4,wefurtheranalyzetheactivecontrol mechanism of the mosquito leg,i.e.,altering the initial stepping angle(ISA)to decrease the supporting force.Owing to thecomplexityofthecouplingbetweenelasticstructuresand capillaryforces,adimensionalanalysismethodisadoptedto discuss the experimental results.

2 Measurement system

We captured mosquitoes(Culex pipiens pallens)from the cities of Jinzhou and Shenyang in northeastern China and bredtheminthelaboratory.Eachmosquitohadsixthin,long legs,withanaverageweightof25μN(yùn).Theaveragelengthof mosquito’s leg is roughly 10-12 mm,and the average radius is 80-100μm.The leg is composed of three segments,i.e., the tarsus,the tibia,and the femur,and two joints link these three portions.At the beginning of the experiments,all the legs were taken from live mosquitoes to keep them fresh and to maintain their actual performance.

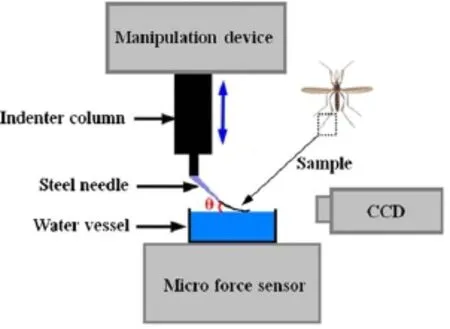

An in situ measurement system developed by the authors wasusedtorecordtheforce-displacementcurves,andexperimental photographs were taken during the entire process,as schematizedinFig.1.Weadheredalivemosquitolegtoafin steel needle,whose function was to adjust the ISA θ fl xibly andconveniently.TheISAisdefine astheanglebetweenthe horizontal water surface and the leg before the leg presses on thewatersurface,asdepictedinFig.1.Intheexperiment,the value of the ISA θ was adjusted to be in a range of 0?-20?, which corresponds to the actual posture of a mosquito leg standing or walking on water.The steel needle was fi ed to a special indenter column modulated by a contacting manipulation device.The device could control the movement of the indenter column upward and downward at certain constant speeds,thereby causing the leg to press against and detach from the water surface in a steady state.A water vessel was placed on a microforce sensor(BT 25S,Sartorius,Gttingen, Germany)with a precision of 0.1μN(yùn).The measured force of the microforce sensor was set to zero when the leg was far from the water surface,i.e.,the weight of the water vessel full of water was compensated in the experiment.Once the leg was in contact with the water surface,the force sensor automatically started to record the curves of the WSF versus the displacement of the indenter column.To monitor the deformation of the leg interacting with the water surface,an optical microscope lens and a charge-coupled device(CCD)camera system were used to record the filat 30 frames per second.

Fig.1 Schematic of developed measurement system

3 Effects of leg’s intrinsic properties

3.1Surface wax and microstructures

As is well known,the hydrophobic property of a solid surfaceisduemainlytotwoaspects:itschemicalingredientsandgeometrictopographies[16-18].Therefore,thesecretedwax and hierarchical structures on the surface of a water stider’s leg have been considered to be predominantly responsible for the superior load-bearing capability of the water strider [4,7].Ithasalsobeenreportedthatwhenawaterstrider’sleg is washed or soaked in an acetone solution,it might lose this strong water supporting ability because these chemicals can remove the layer of wax coating on the leg[19,20].However,for a mosquito leg,the real role of the surface wax and microstructures in producing the leg’s huge WSF remains a puzzle.As a consequence,we conducted comparative experimentsonahindlegofamosquitowiththeaimofunraveling this mystery.

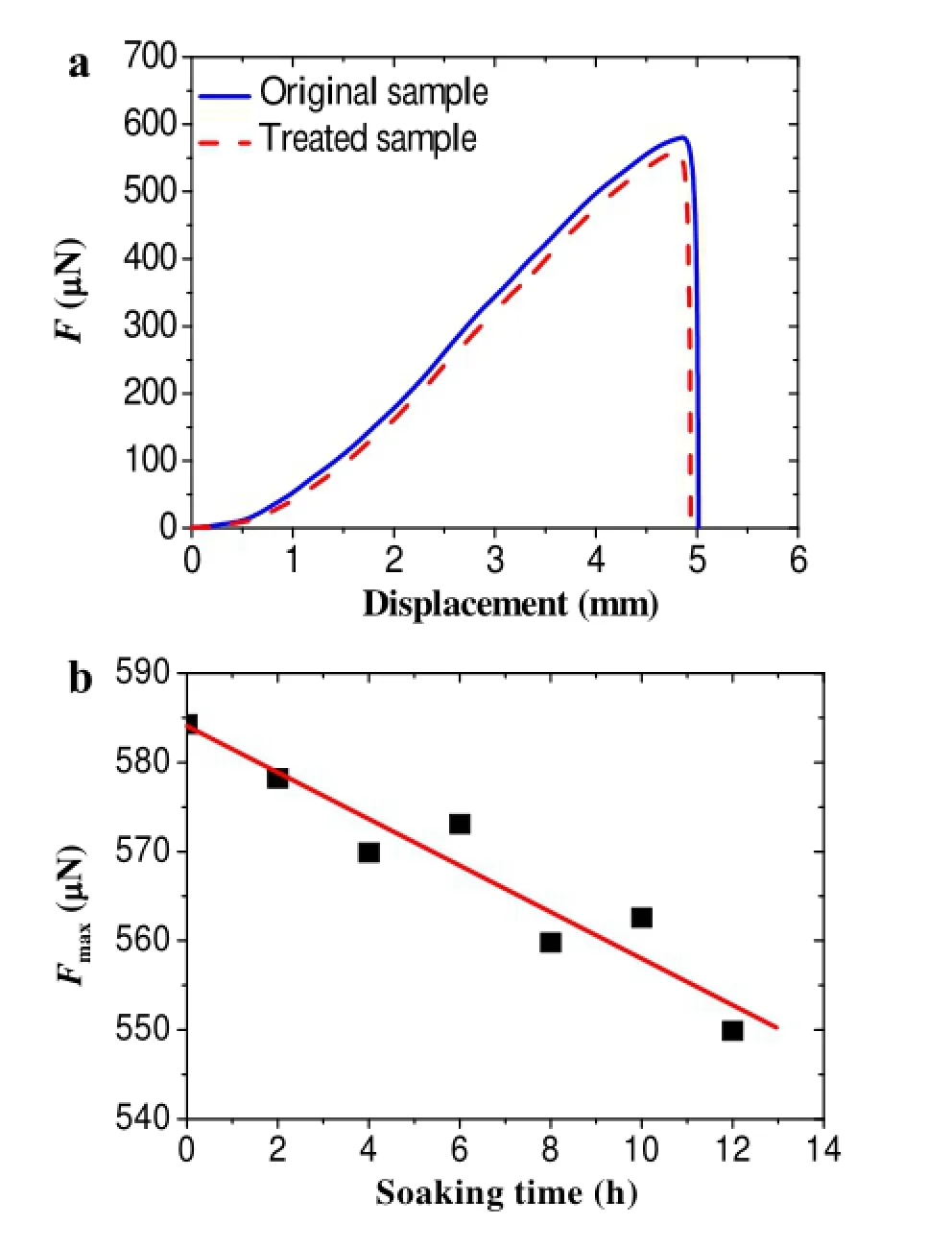

First,two typical mosquito legs were selected with the same radius R≈90μm and length L=11 mm.The forcedisplacement curves for these two samples were obtained using the measurement system we developed.Next,the firs leg was soaked in a solution of acetone(40ml/L)for 4h and thenremovedandplacedonthesurfaceoffilte papertocause the remaining acetone on the leg surface to completely evaporate.The force-displacement curves for the wax-removed sample and the original sample are shown in Fig.2a.Note that as the displacement of the indenter column increases, the WSF(denoted by F)gradually increases until it reaches a peak point,the maximum value.Following the peak,the forcesuddenlyjumpstozero,i.e.,thelegpenetratesthewater surface.ThemaximumWSFatthecriticalpointisdenotedby Fmax,whose value is measured to be(585±5)μN(yùn),which is approximately23timesthebodyweightofasinglemosquito. The two curves also reveal that there is no significan differenceintheWSFofthelegbeforeandafterbeingtreatedwith acetone solution.The maximum WSF for the treated leg is (570±5)μN(yùn),which is only approximately 2.5%less than that of the untreated sample,and we denote the maximum force difference by ΔFmax(here its value is 15μN(yùn)).Moreover,we measure the WSF of the leg for different soaking times in the acetone solution.The relationship between the maximum WSF Fmaxand the soaking time of the leg in acetone is depicted in Fig.2b.It can be seen in the figur that even if the leg is soaked in the acetone for more than 12h, and more wax is removed,the maximum value of the supporting force decreases by just 6%.It seems that,in contrast to earlier assumptions,the wax coating is not very important for enhancing the WSF of the mosquito leg.

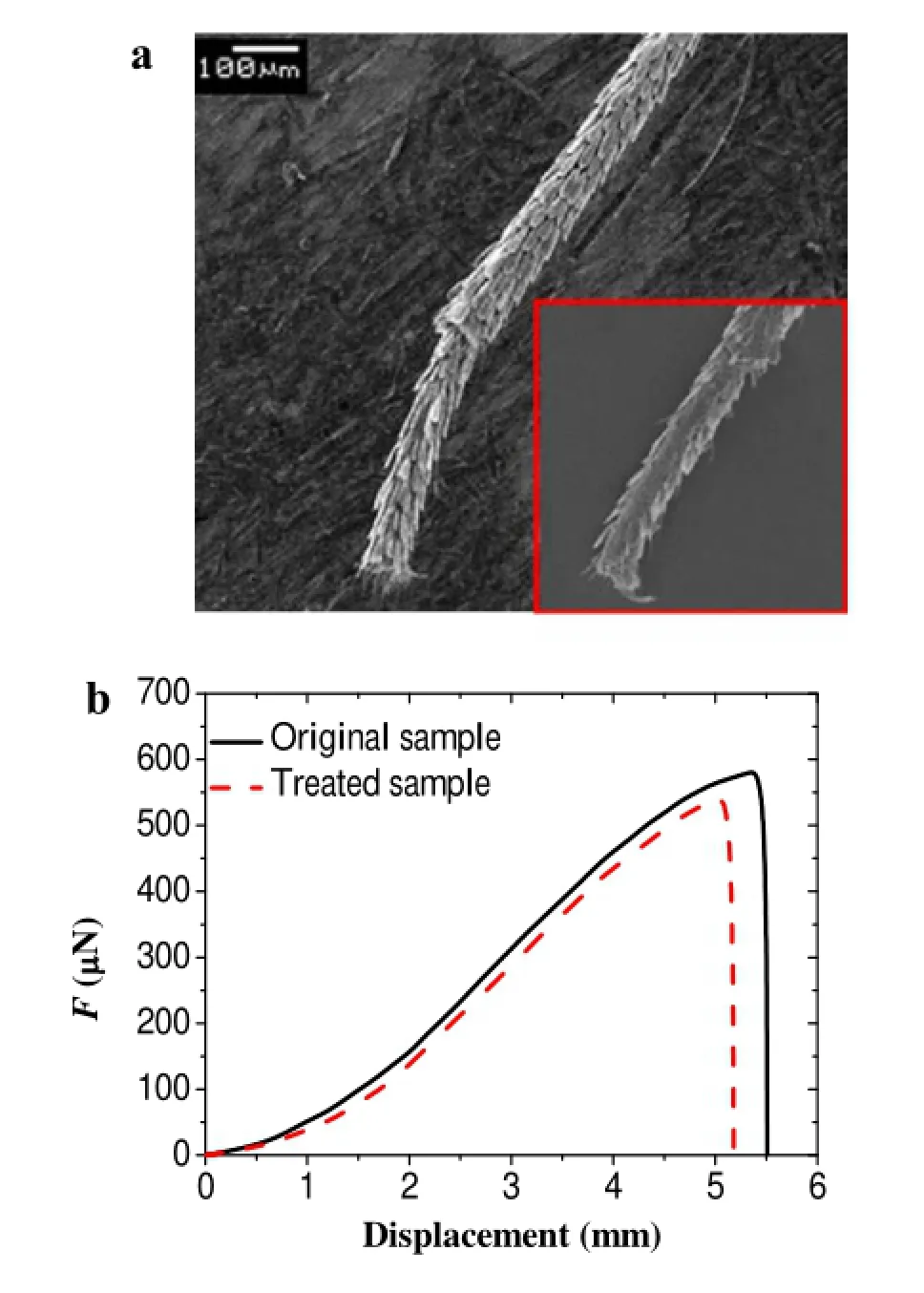

For the second leg,we investigated the impact of surface microstructures on the WSF.The images on the surface topographies were taken on a field-emissio scanning electron microscope(SEM)(JSM-6700F,JEOL,Beijing,China)at 3.0 kV,and the samples were sputtered with a layer of gold 10 nm thick prior to imaging.From the SEM image in Fig.3a it can be observed that the mosquito leg is covered with numerous oriented scales that consist of uniformly distributed microscales,i.e.,longitudinal ridges and nanosized cross ribs.We carefully wiped off most of the scales in succession(more than 80%of the total volume)with a fin steel needle,and from the inset of Fig.3a it can be seen that the treated sample was in its smoothest state.Then the surface-smoothed leg was placed on our measurement system.The force-displacment curve is displayed in Fig.3b in comparison with the original one.The figur shows that the maximum WSF of the original leg with full scales was (583.7±5.0)μN(yùn),while that of the treated leg that had lost most of its scales was(545.8±5.0)μN(yùn),with a deviation of only ΔFmax=38μN(yùn).This result indicates that a nearly smooth mosquito leg can also produce a sufficientlhigh WSF,and the microstructures on the leg surface are not as significan as previously thought[15].

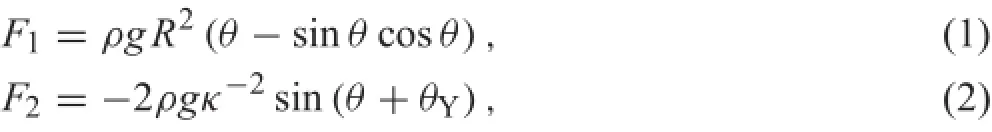

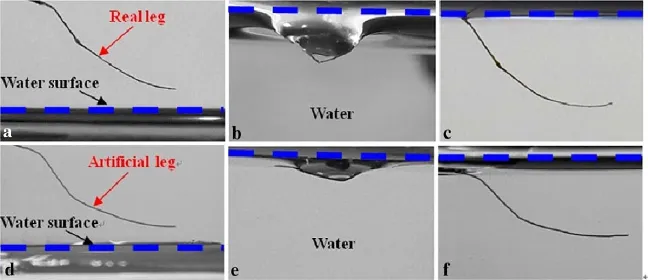

Whythesurfacewaxandmicrostructuresdonotaffectthe WSF very much can be addressed with reference to a twodimensionalmodelofarodfloatin onwater[6-9].TheWSF F originates from three terms:F=F1+F2+F3,where the analytical solutions of the three terms are expressed as follows[9]:

Fig.2 Effect of wax coating on WSF of mosquito leg.a Comparison offorce-displacementcurveofmosquitohindlegbeforeandafterbeing soaked in acetone solution for 4h.b Dependence of maximum WSF on soak time of leg in acetone solution

Fig.3 Effect of microstructures on WSF of mosquito leg.a SEM image of a leg full of numerous oriented microscales,where the inset shows most of the leg scales removed.b Comparison of forcedisplacement curve of mosquito hind leg before and after removal of most scales

The symbol κ?1=is the so-called capillary length,where γ and ρ are respectively the surface tension and mass density of the liquid,and g is the gravitational acceleration.The parameter α is an angle related to how deep the leg is in the water(define in Ref.[9]),and θMis the macroscopic contact angle of the leg surface.According to Eqs.(1)-(3),it can be seen that F1~R2,F2~κ?2, and F3~κ?1R.For pure water under normal temperatures, tt hh e an c t ahpei l a la v reyr a lgeen gr a th d i κu ?s 1of≈ a m2.o7s1qmuimto, lewgh,iic.he. ,is9 0mμucmh ilna rtgheisr paper.As a consequence,the scaling law of the WSF can be approximated as F~κ?2sin(α+θM),and Fmax~κ?2sinc In e f|asi cnt,(tαhe+ fuθnM d)a|m≤en1t.al ingredient of the mosquito leg is chitin,which possesses a weaker hydrophobic property and hasaYoung’scontact angleinarange of95?-105?[21].The normal Young’s contact angle of wax has been estimated as 120?[4,7].In addition,experimental observations showed that the hierarchical microstructure on the leg surface could trap a thin layer of air when the leg is pressed onto water[4, 7,9];thus,the macroscopic contact angle of a real mosquito leg can be predicted by the Cassie-Baxter model[22],

where θYis the Young’s contact angle or the characteristic contact angle of the surface material,and φSis the percentageofthesolid-liquidinterfaceareatothetotalcomposite interfacial area.According to the sizes and scale bar of Fig.3a,the width of the microscale is a=3.5μm, and the distance between two neighboring microscales is b=12.5μm;thenthepercentageratiocanbeapproximated as φS=a/b=28%.For the firs treated sample without wax,the Young’s contact angle is selected as θY=95?,and the macroscopic contact angle can be calculated as 138.11?according to Eq.(1).For the second treated sample without microstructures,φS=0,and the Young’s contact angle is selected as θY=120?as the wax remains;then the macroscopic contact angle is 120?.For the original mosquito leg, θY=120?and φS=28%;then the macroscopic contact angle is 149.32?.Although the macroscopic contact angles for the three cases are different,the aforementioned scaling law tells us that the maximum values of the WSFs should be very close to each other.The difference lies in the positions of the extreme points,and this analysis is consistent with the experimental curves.This theoretical model reemphasizes that the extremely large WSF of the mosquito leg is insensitive to the wetting property of the leg surface.It should be stressed that,despite the slight contribution of the scales to the WSF,the hierarchical microstructures can trap a thin layer of air around the leg surface,which ensures that the mosquito leg is not easily wetted by water,and can lower the wet adhesion and energy dissipation during locomotion on water surfaces[21,23].

3.2Flexibility

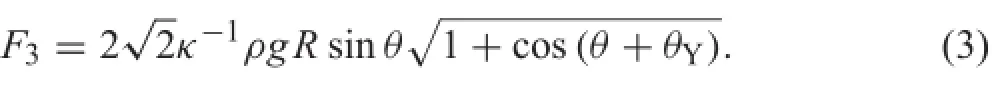

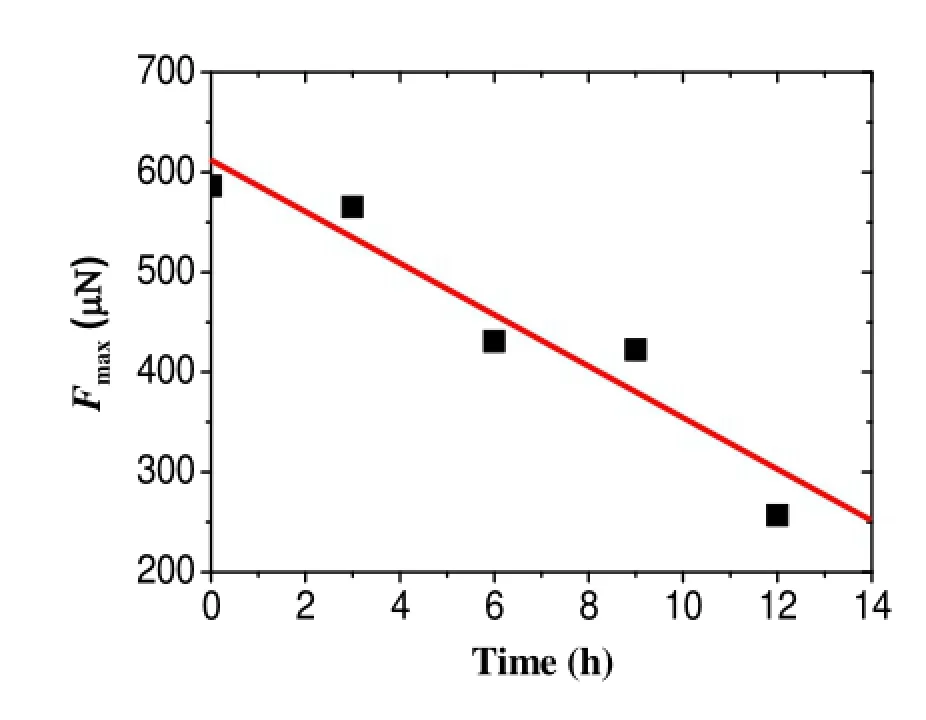

Though the surface wax and microstructures are not very important components of the load-bearing capability of the mosquito leg,in what follows,we show that the leg’s fl xibility is a crucial component of such a large WSF.The deformation of a mosquito leg pressing on water was captured by a synchronized CCD camera system(Fig.4a-c). Notethatwhenpressedontothewater,thewholelegdeforms into a V-shape through the fl xible joint near the tibia,and theotherjointisabovethewatersurfaceandnotimmersedin thewaterduringtheprocess.Thefigur showsthatthedeformation near the leg joints is a main reason for the large WSF because it helps to repel more water.It is known that the leg will lose a certain amount of fl xibility and become stiffer following its isolation from the body of a living mosquito after a period of time.It is at this point that we put the mosquito leg in the air to change its stiffness.The dependencerelationshipbetweenthemaximumWSFandtimeisdemonstrated in Fig.5,which shows that with the passage of time, thelegbecomesstifferandisaccompaniedbyasmallerWSF. For example,after 12h the measured maximum WSF is only approximately(281±5)μN(yùn),decreasing by nearly 53.0%. When this leg is put the air several days later,it becomes sufficientl dryandfragileandrapidlycollapsesonceincontact with water.

Fig.4 Typical images showing the deformation of a real mosquito leg and an artificia one on water.a-c Real leg.d-f Artificia leg

Fig.5 Effect of fl xibility on maximum WSF of mosquito leg

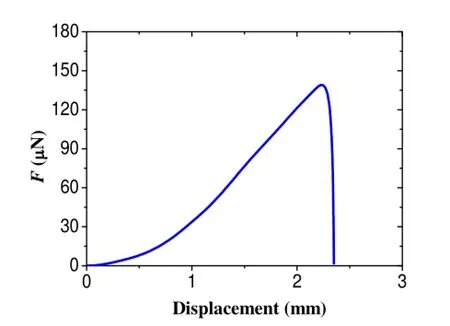

Fig.6 Typical curve measured for WSF of artificia leg versus displacement

As a comparison,the experiment was repeated with an artificia leg designed to mimic a real mosquito leg.The artificia leg was made of a steel wire with rigid joints and had thesameshapeandsizeasarealleg.Theforce-displacement curveofthisartificia legisshowninFig.6,andthemeasured maximum WSF is only(148±5)μN(yùn),much smaller than that of a real mosquito leg,even when it is dried after 12h. This is because,although the artificia leg is slender,it is still stifferthanareallegafter12hofdrying.ThemaximumWSF differencebetweenthesetwolegsis134μN(yùn),whichindicates that besides the surface wax and microstructures,fl xibility plays a more significan role.The morphology of the contact interface between the artificia leg and the water surface is shown in Fig.4d-f,where a much smaller puddle is formed than when a real leg is involved.Comparing Fig.4b with e, one find that there is another difference between the deformation ofa real mosquito leg and an artificia one,especially near the right joints of the legs.This difference stems from the fact that for the mosquito,the joints can rotate with a certain degree of freedom,but the artificia leg has rigid joints, so it cannot deform like a real leg.

Thebigdifferencebetweenthefl xibleandstifferlegscan befurtherexplainedasfollows.Accordingtothegeneralized Archimedes principle[6-9],the force supported by water is proportional to the volume of water displaced by a dimple V in contact with the leg:

The scaling law for the dimple volume is V=V(L,h,E,R,γ),where E is the Young’s modulus of the leg and h is thecharacteristic length of the dimple,e.g.,its maximum depth. Thevolumecanbeintegratedifthemorphologyofthedimple z=z(x,y)is given,which is determined via the Laplace equation

where Δp is the Laplace pressure difference across the liquid-vaporinterface.Themaximumdepthofareallegpenetratingwaterisaround3mm,whilethatofanartificia legis only around 1mm.This experimental result can be verifie bythescalinglawofthedepthparameter,whichisexpressed as h~ΔpL4/E~γ L3/E using the Euler-Bernoulli beam model.Dimensional analysis shows that the dimple volume is scaled as V~Lh2;thus,the softer the leg,the larger the dimplevolume.Theoreticalanalysisisinagreementwiththe experimentalresultthatafl xiblelegrepelsmuchmorewater thananartificia legandcancreateamuchlargerforce.These results are also in agreement with previous conclusions indicating that in the hydrophobic case,a compliant sheet is able to produce a larger buoyant force than a stiff one[11-14].

To summarize the finding of this section,the contributions of the intrinsic properties of a leg to the WSF can be expressed by the percentage ratio f=ΔFmax/Fmax×%: surfacewaxaccountsfor f=2.5%-6%withdifferentdurationsofacetonesoaking,andsurfacemicrostructuresaccount for f=6.5%.In cases where a leg’s fl xibility diminishes following 12h of drying(Fmax=(281±5)μN(yùn),ΔFmax= 304μN(yùn)),the wax,microstructures,and fl xibility remain; therefore,the the leg’s fl xibility accounts for more than f=53.0%of the WSF.The other contributions to the WSF of the mosquito leg may stem from surface tension or the contactpostureofthelegwithwater.Thesewillbediscussed subsequently in more detail.

4 Active control of the ISA

Besides the intrinsic properties of its legs,the mosquito possesses a special ability to actively control the ISA θ,in particular during walking,takeoff,and landing on a water surface.In most cases,the ISA is confine within a range of 0?-20?,butwhyittakesthisparticularvalueremainsanopen question.We measured the maximum WSF with different ISAs,and the result is presented in Fig.7.It can be seen that the load-bearing capability of the mosquito on water is quite sensitive to the ISA on water surfaces.As the ISA increases, the maximum WSF of the leg decreases significantl,from 585μN(yùn) to nearly 0,corresponding to a variation in the ISA from 0?to 90?.The greatest force appears when the ISA is in a range of 0?-20?,which corresponds to the ordinary posture of a leg standing on a water surface.In addition,in this range,the maximum force is almost identical for different angles,which agrees well with previous results[15]. When θ is greater than 62?,the leg penetrates water,and the maximumvalueisonlyseveralmicronewtons.Thisisalsoin agreement with the theoretical work by Liu et al.[24],who investigated cases where a cylindrical fibe vertically penetrates water.To be more applicable in biomimetic designs, the function of the maximum WSF with respect to the ISA can be approximately fitte as a trigonometric function:

Fig.7 Effect of ISA on maximum WSF of mosquito leg

When a mosquito regulates the ISA,in fact,the contact length of the leg with water is adjusted.It is already known that the wet adhesion forces between the leg and water are nearly proportional to the contact length[23],and different segments of the mosquito leg have different capacities to produce a WSF[25].The smaller the ISA is,i.e.,the leg is in contact with water in a nearly horizontal orientation,the larger the contact length;whereas the larger the ISA(90?), that is,the leg makes contact with the water in a vertical orientation,the length,L,equals 0,and the leg tends to penetrate the water,while at the same time the WSF approaches zero[24].Therefore,it is observed that under normal conditions,this intelligent creature uses its tarsus to make contact with the water surface because this provides sufficien supporting force for standing or walking on water[25].In some extreme situations,such as during a rainstorm,to enhance the WSF,the mosquito can modulate the ISA and cause the three segments tobecome tightlyfi ed on the water.Another advantage of ISA regulation is that it assists in taking off from the water surface.As an intelligent creature,the mosquito is able to control the ISA and the contact length of itsleg on water,which helps it to reduce the wet adhesion force andenergydissipationduringtakeoff.Infact,thisbehavioris an optimization strategy that allows the mosquito to realize a huge supporting force and reduce the adhesion force for takeoff,the result of millions of years of evolution.

5 Conclusion

The physical and biological functions that affect the WSF of a mosquito leg were systematically explored using a measurement system developed by the authors and by applying theoretical analysis.These factors can be grouped into two types:theintrinsicpropertiesofthelegsurfaceandtheactive controloftheISAofthewholeleg.TheWSFsoftheoriginal leg samples were compared with those with surface wax and microstructuresremovedandthosewithdifferentstiffnesses. The results show that their contributions to the WSF can be evaluated using a percentage ratio:surface wax accounts for 2.5%-6%of the WSF with different durations of acetone soaking,the surface microstructures account for 6.5%of the WSF,andthelegfl xibilitycanaccountformorethan53.0% of the WSF.In addition,as an intelligent creature,the mosquito can actively control the ISA to increase the contact length of the leg with water,enhancing the WSF to become fi ed on water during a rainstorm,and reduce the contact length to lower the wet adhesion force and energy dissipation during takeoff.

However,muchremainstobedoneinfutureexplorations; for example,an accurate mechanical model or numerical simulations are needed to analyze the interplay between the fl xiblelegandthewater-airinterface,wherefinit deformation and fluid-soli coupling theories should be considered. Nevertheless,the present finding deepen our understanding of the locomotion mechanism of aquatic insects and shed light on the design of microfluids small boats,biomimetic robots,and microsensors.

AcknowledgmentsThis work was supported by the National Natural Science Foundation of China(Grants 11302093,11302094 and 11272357)and the Natural Science Fund for Distinguished Young Scholars of Shandong Province(JQ201302).

References

1.Wilcox,R.S.:SexdiscriminationinGerrisremiqis:roleofasurface wave signal.Science 206,1325-1327(1979)

2.Suter,R.B.,Wildman,H.:Locomotiononthewatersurface:hydrodynamic constraints on rowing velocity require a gait change.J. Exp.Biol.202,2771-2785(1999)

3.Hu,D.L.,Bush,J.W.M.:The hydrodynamics of water-walking arthropods.J.Fluid Mech.644,5-33(2010)

4.Gao,X.F.,Jiang,L.:Water-repellent legs of water striders.Nature 432,36(2004)

5.Hu,D.L.,Chan,B.,Bush,J.W.M.:The hydrodynamics of water strider locomotion.Nature 424,663-666(2003)

6.Keller,J.B.:Surface tension force on a partly submerged body. Phys.Fluids 10,3009-3010(1998)

7.Feng,X.Q.,Gao,X.F.,Wu,Z.N.,et al.:Superior water repellence ability of water strider’s legs with hierarchical structures:experiments and analysis.Langmuir 23,4892-4896(2007)

8.Vella,D.,Lee,D.G.,Kim,H.Y.:Sinking of a horizontal cylinder. Langmuir 22,5979-5981(2006)

9.Liu,J.L.,Feng,X.Q.,Wang,G.F.:Buoyant force and sinking conditions of a hydrophobic thin rod floatin on water.Phys.Rev.E 76,066103(2007)

10.Zheng,Q.S.,Yu,Y.,Feng,X.Q.:The role of adaptive-deformation of water strider leg in its walking on water.J.Adhes.Sci.Technol. 23,493-501(2009)

11.Ji,X.Y.,Wang,J.W.,Feng,X.Q.:Role of fl xibility in the water repellency of water strider legs:theory and experiment.Phys.Rev. E 85,021607(2012)

12.Burton,L.J.,Bush,J.W.M.:Can fl xibility help you float Phys. Fluids 24,101701(2012)

13.Vella,D.:Floating objects with finit resistance to bending.Langmuir 24,8701-8706(2008)

14.Park,K.J.,Kim,H.Y.:Bending of floatin fl xible legs.J.Fluid Mech.610,381-390(2008)

15.Wu,C.W.,Kong,X.Q.,Wu,D.:Micronanostructures of the scales on a mosquito’s legs and their role in weight support.Phys.Rev.E 76,017301(2007)

16.Quere,D.:Rough ideas on wetting.Phys.A 313,32-46(2002)

17.Otten,A.,Herminghaus,S.:How plants keep dry:a physicist’s point of view.Langmuir 20,2405-2408(2004)

18.Patankar,N.A.:On the modeling of hydrophobic contact angles on rough surfaces.Langmuir 19,1249-1253(2003)

19.Caponigro,M.A.,Erilsen,C.H.:Surface fillocomotion by the water strider.Gerris remigis say.Am.Midland Nat.95,268-278 (1976)

20.Peng,Y.,Zhou,M.X.:Study on the structure and hydrophobicity of water strider’s tarsus.Biol.Teach.3,66-68(2012)

21.Kong,X.Q.,Wu,C.W.:Superiorwaterrepellencyofmosquitolegs with hierarchical micro-nanostructures.Chin.Sci.Bull.16,1589-1594(2010)

22.Cassie,A.B.D.,Baxter,S.:Wettability of porous surfaces.Tran. Faraday Soc.40,546-551(1944)

23.Su,Y.W.,Ji,B.H.,Huang,Y.G.,etal.:Nature’sdesignofhierarchical superhydrophobic surfaces of a water strider for low adhesion and low-energy dissipation.Langmuir 26,18926-18937(2010)

24.Liu,J.L.,Sun,J.,Mei,Y.:Biomimetic mechanics behaviors of the strider leg vertically pressing water.Appl.Phys.Lett.104,231607 (2014)

25.Kong,X.Q.,Liu,J.L.,Zhang,W.J.,et al.:Load-bearing ability of the mosquito tarsus on water surfaces arising from its fl xibility. AIP Adv.5,037101(2015)

24 February 2015/Revised:11 March 2015/Accepted:20 March 2015/Published online:14 August 2015

?Jian-Lin Liu liujianlin@upc.edu.cn

1School of Civil and Architectural Engineering,Liaoning University of Technology,Jinzhou 121001,China

2Department of Engineering Mechanics,China University of Petroleum,Qingdao 266580,China

3Department of Engineering Mechanics,Dalian University of Technology,Dalian 116023,China

- Acta Mechanica Sinica的其它文章

- Acoustic emission assessment of interface cracking in thermal barrier coatings

- An efficien formulation based on the Lagrangian method for contact–impact analysis of flexibl multi-body system

- Correcting the initialization of models with fractional derivatives via history-dependent conditions

- Impact toughness of a gradient hardened layer of Cr5Mo1V steel treated by laser shock peening

- The equilibrium stability for a smooth and discontinuous oscillator with dry friction

- Analysis of the geometrical dependence of auxetic behavior in reentrant structures by finit elements