Calculation of Surface Excitation Parameters by a Monte Carlo Method

Zhe Zheng,Bo D,Shi-feng Mo,Ze-jun Ding

a.CAS Key Laboratory of Geospace Environment,Department of Modern Physics,University of Science and Technology of China,Hefei 230026,China

b.National Institute for Materials Science,1-2-1 Sengen,Tsukuba,Ibaraki 305-0047,Japan

c.School of Nuclear Science and Technology,University of Science and Technology of China,Hefei 230026,China

d.Hefei National Laboratory for Physical Sciences at the Microscale and Department of Physics, University of Science and Technology of China,Hefei 230026,China

(Dated:Received on July 23,2016;Accepted on September 17,2016)

Calculation of Surface Excitation Parameters by a Monte Carlo Method

Zhe Zhenga,Bo Dab,Shi-feng Maoc,Ze-jun Dingd?

a.CAS Key Laboratory of Geospace Environment,Department of Modern Physics,University of Science and Technology of China,Hefei 230026,China

b.National Institute for Materials Science,1-2-1 Sengen,Tsukuba,Ibaraki 305-0047,Japan

c.School of Nuclear Science and Technology,University of Science and Technology of China,Hefei 230026,China

d.Hefei National Laboratory for Physical Sciences at the Microscale and Department of Physics, University of Science and Technology of China,Hefei 230026,China

(Dated:Received on July 23,2016;Accepted on September 17,2016)

Electron inelastic mean free path(IMFP)is an important parameter for surface chemical quanti fi cation by surface electron spectroscopy techniques.It can be obtained from analysis of elastic peak electron spectroscopy(EPES)spectra measured on samples and a Monte Carlo simulation method.To obtain IMFP parameters with high accuracy,the surface excitation e ff ect on the measured EPES spectra has to be quanti fi ed as a surface excitation parameter (SEP),which can be calculated via a dielectric response theory.However,such calculated SEP does not include in fl uence of elastic scattering of electrons inside samples during their incidence and emission processes,which should not be neglected simply in determining IMFP by an EPES method.In this work a Monte Carlo simulation method is employed to determine surface excitation parameter by taking account of the elastic scattering e ff ect.The simulated SEPs for di ff erent primary energies are found to be in good agreement with the experiments particularly for larger incident or emission angles above 60°where the elastic scattering e ff ect plays a more important role than those in smaller incident or emission angles.Based on these new SEPs,the IMFP measurement by EPES technique can provide more accurate data.

Eelastic peak electron spectroscopy,Surface excitation parameter,Monte Carlo simulation

I.INTRODUCTION

The electron inelastic mean free path(IMFP)is a parameter of fundamental importance to quantitative surface chemical analysis by surface electron spectroscopy,e.g.X-ray photoelectron spectroscopy(XPS) and Auger electron spectroscopy(AES).Lots of ef f orts have been put on the measurements of IMFP for various materials by using elastic peak electron spectroscopy (EPES)[1–3],with which the IMFP value can be deduced with assistance of a Monte Carlo(MC)simulation.However,there is still a discrepancy of IMFP data between theoretical calculation and experimental measurement,which has been attributed to dif f erent sources,e.g.the simplif i cation in the corresponding MC simulation:the accuracy of electron elastic scattering cross-sections[4],the choice of the modeling dielectric function[5],the surface excitation ef f ect mostly ignored,and surface roughness[1,6].According to previous studies[3,7–9],surface excitations which occur due to electrons crossing the surface are likely to be the major factor for the deviation.Therefore,in order to obtain more precise IMFP data from the EPES method, it is necessary to investigate in detail the inf l uence of the surface excitation on the elastically backscattered electrons and to quantitatively estimate this surface excitation ef f ect.

Surface excitation parameter(SEP)has been introduced to characterize the surface excitation probability, which was def i ned as the average number of excitations generated by an electron moving across the solid surface once[10–12].A variety of theoretical studies on the SEP has been done,with dif f erent methods for evaluation and quantif i cation of surface ef f ects through determination of SEP.Tung et al.[10]considered the surface excitation ef f ect in an oversimplif i ed model in which the surface excitations occur just at the surface boundary without extending to both sides of the surface boundary. Chen et al.,Kwei et al.,and Li et al.[11,13,14]used a semi-classical expression of the position-dependent differential inverse IMFP(DIIMFP)to evaluate the surface excitation ef f ect,which decays exponentially on both the vacuum-and solid-sides.The SEPs were calculated from an integration of dif f erential surface exci-tation probability over the electron distance from the surface to vacuum for incident and escaping electrons with the assumption of a spatially non-varying total electron IMFP inside the solid.According to this assumption,a particular aspect of surface ef f ects is however neglected,namely the Begrenzungs ef f ect,i.e.,the decrease in the bulk inelastic cross-section close to the surface due to the coupling between the volume and surface modes that are orthogonal[15].Then,Salma et al.[12]and Da et al.[16]calculated SEP from the integration of dif f erential surface excitation probability for both vacuum and solid sides by a quantum-mechanical approach and the semi-classical approach respectively. These SEPs were calculated from the integration of differential surface excitation probability with the assumption that electrons cross the surface from inside inf i nity to outside inf i nity;but practically the signal electrons in the EPES method are backscattered from the sample within a very small probed depth especially in low energy case.That implies that the SEP obtained within such an integration method is not appropriate to be a correction factor for elastic peak intensity.In order to obtain more suitable SEP,an alternative def i nition of the SEP has been given by Pauly and Tougaard [17].They proposed to use the change in the excitation probability of an electron caused by the presence of the surface in comparison with an electron moving in an inf i nite medium for def i nition of the SEP.In their recent work[18],a SEP database was built employing this def i nition by a software named quantitative analysis of electron energy losses at surface(QUEELS)[19], which implements a semi-classical model of Yubero and Tougaard[20]based on V-type trajectory assumption. Due to this V-type trajectory,all the signal electrons collected in EPES were treated as suf f ering once and only once elastic scattering.However,this assumption is not precise enough to describe the elastic scattering in practical EPES measurement,because the trajectory of signal electrons is generally quite complex due to multiple elastic collisions especially for low energy electrons.In order to obtain more precise IMFP from EPES method,it is thus necessary to investigate the inf l uence of elastic scattering on the SEP calculation and quantitatively estimate this total surface excitation ef f ect in EPES.

In our previous studies[21–23],a MC model was built by taking into account the details of surface excitation to study how the surface excitation af f ects EPES spectra as well as ref l ection electron energy loss spectroscopy (REELS)spectra.The purpose of this work is then to obtain the quantitative measure of elastic peak intensity af f ected by the surface excitation and to obtain corresponding SEP by considering inf l uence of elastic scattering in EPES,based on this MC model.The simulations of EPES are performed for Au,Cu,Fe,Ni and the simulated results are found to agree well with experimental observation.Based on these calculated elastic peak intensities by including or excluding surface excitation,the SEP containing the inf l uence of elastic scattering can be determined.

II.THEORETICAL METHODS

A.Electron elastic scattering

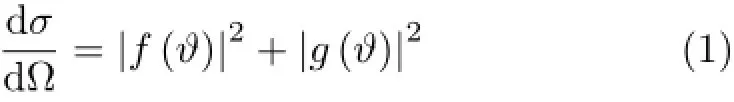

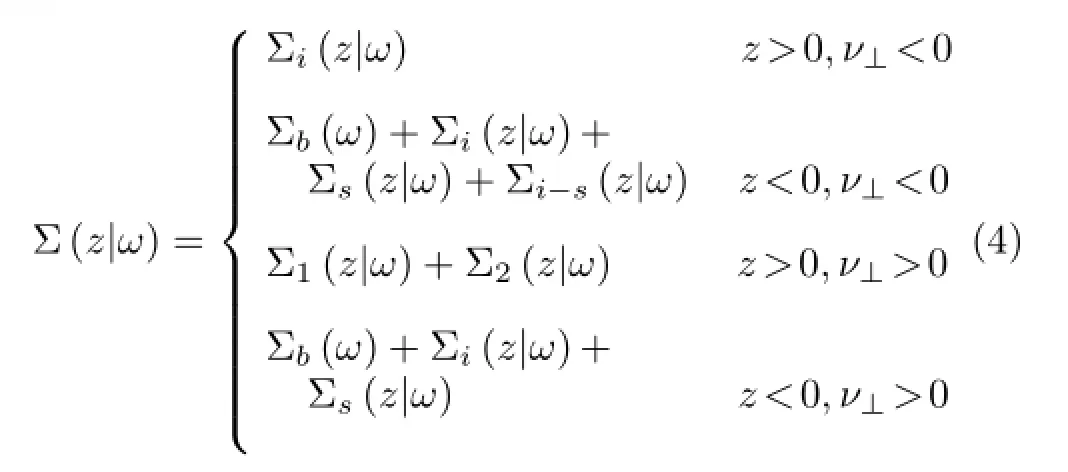

The Mott’s cross section[24]is employed in this study for the treatment of electron elastic scattering:

where the scattering amplitudes,

are calculated by the partial wave expansion method [25].In the above equation P?(cos?)andare,respectively,the Legendre and the f i rst-order associated Legendre functions.spin-down phase shifts of the ?th partial wave,respectively.The phase shifts are numerically evaluated by solving the Dirac equation for the radial part of the wave function of the scattered electron.In this calculation the Thomas-Fermi-Dirac atomic potential[26]is employed.B.Inelastic scattering

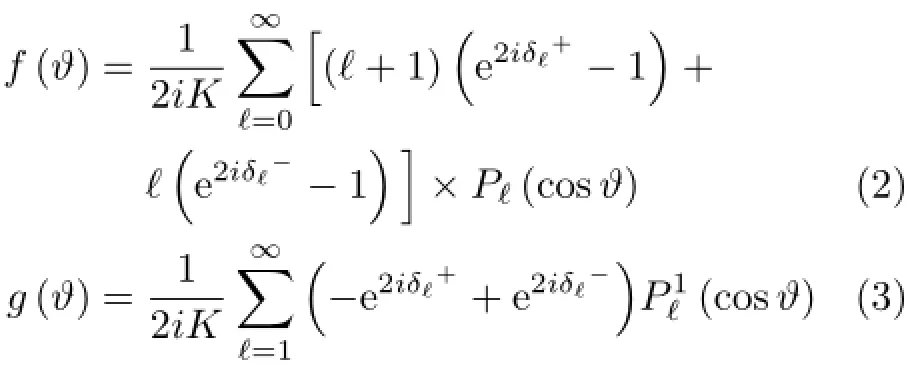

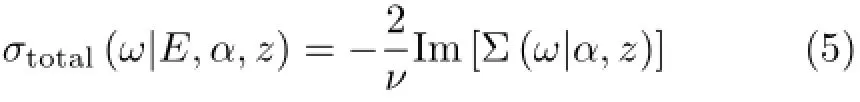

Electrons moving near a surface will undergo inelastic scattering through bulk electronic excitation and surface electronic excitation.The inelastic scattering probability is governed by bulk dielectric function ε(q,ω)of the solid in a dielectic response theory.In the specular surface re fl ection model[27,28]the general discussions on the surface response function and the electron self-energy have been made previously[29–31].The random-phase-approximation self-energy of an electron is expressed in terms of the bulk dielectric function of the specimen based on a vanishing surface potential and a fast-electron approximation.The corresponding differential self-energy inhomogeneous in z-direction for various positions and directions of moving electrons is provided as follows:

where Σb,Σi(z|ω),Σs(z|ω),and Σi-s(z|ω)are respectively the bulk term,the image charge term,the surface charge term and the interference term between the image charge and the surface charges,respectively[35,36]. Here,ν⊥is the vertical component of velocity vector; the vertical distance z measured from the surface is positive in vacuum and negative in solid.Then a DIIMFP can be obtained numerically from the imaginary part of the dif f erential self-energy

It is reasonable that the total DIIMFP are inhomogeneous in the z-direction.IIMFP can be easily calculated numerically by an integration of DIIMFP over the energy loss ω.This surface excitation model is referred to as the surface model hereafter.When only the bulk term Σbis considered,it is the conventional bulk excitation model and referred to as the bulk model.

C.Monte Carlo simulation

By employing the local inelastic cross section and Mott elastic cross section we have performed a number of MC simulations of EPES spectra for dif f erent materials.In this MC simulation of electron scattering processes,the f l ight length s between successive individual scattering events is sampled from an exponential probability distribution

where the total cross section σ(s)is the sum of the elastic scattering cross section and the local inelastic scattering cross section.Because the total cross-section σ(s)is dependent on the position and direction of an electron,hence,it is expressed here as a function of the f l ight length.Considering the inhomogeneity of the cross-section is dependent on the depth,the actual variable involved in sampling is the depth z.Knowing the electron moving direction,the step length s and the coordinates of next scattering position of the moving electron can be determined.The detail of this simulation can be found in our previous reports[21,32,34].

III.RESULTS AND DISCUSSION

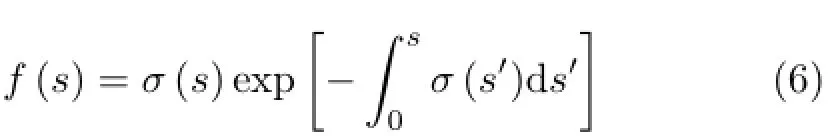

FIG.1 Comparison on the energy dependence of elastic peak intensity normalized by the incident beam current, i.e.the number of elastically scattered electrons per primary electron,for Ni between experimental data(squares) measured by a CMA with a Faraday cup,and the present MC simulations by surface model(circles)and bulk model (triangles)at the same conditions(incident beam and detector geometry)as the experiment.The deviations between simulated(surface model)and experimental results are also shown as errors.

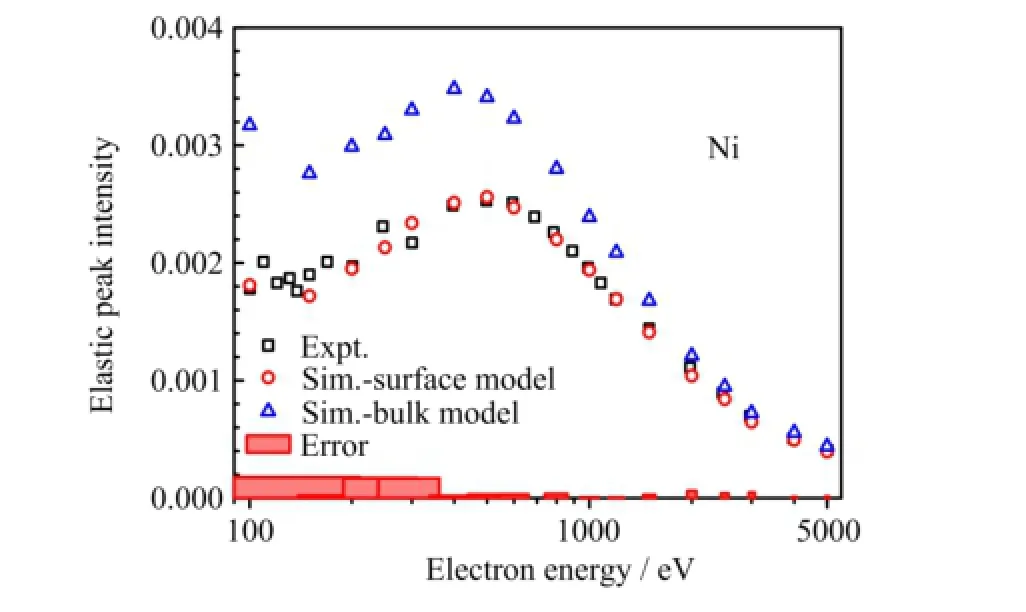

FIG.2Ratios of measured elasticpeak intensities[35] (squares)and simulated elastic-peak intensities(circles)for Ag,Au and Cu to those of Ni as a function of electron energy.

FIG.3 Comparison on the emission angular dependence of elastic peak intensity between an experiment[36]and a MC simulation for normal incidence of primary electrons of(a-d)500 eV and(e-h)1000 eV onto(a,e)Ag,(b,f)Au,(c,g) Cu and(d,h)Ni surfaces with analyzer acceptance angle of±41°.

In order to obtain the quantitative information of surface excitation in EPES,the f i rst step is to ensure the validity and correctness of our MC model for simulating EPES spectra by including surface ef f ect.Figure 1 shows a comparison on the energy dependence of elastic peak intensity for Ni between simulations by including surface excitation(surface model)and excluding surface excitation(bulk model)and experimental data[3]measured with a cylindrical mirror analyzer(CMA),which is coaxial with an electron gun at normal incidence,and a Faraday cup.Here,we ignore the energy dependence of electron transmission efficiency of the CMA mesh. As shown in Fig.1,the simulated elastic peak intensity of Ni by including surface excitation agrees excellently with the measured results,and the corresponding error describing the deviations from the experiment also comes to the same conclusion.It is noticed that there is a considerable deviation from experiment,for example,exceeding by 40%at 400 eV,when only considering bulk excitation in the simulation especially at low energies below 2 keV.Employing this surface model in MC simulation,we have also calculated elastic peak intensities for several other typical metals.Figure 2 shows the ratios of the measured[35]and simulated elastic peak intensities of Ag,Au and Cu to the corresponding intensities of Ni reference as a function of electron energy. The simulated elastic peak intensities agree well with the measured results,especially for Au and Cu.It is obviously that both experiment and calculation for these presented intensities including Ni shown in Fig.1 indicate some features at low energy,for example,around 100-150 eV for Ni.These features in the energy dependence are due to strong peak for electron backscattering according to dif f erential elastic scattering cross section at such energy.Here we have also simulated the angle-resolved EPES for these materials.Figure 3 shows a comparison on the emission anglar dependence of the elastic peak intensity between the experimental data[36]and simulation results for Ag,Au,Cu,and Ni for 500 and 1000 eV electrons.The simulation agrees very well with measurement especially for Au,Cu and Ni;however,there is a general tendency to an underestimation of the simulated intensities of Ag at large emission angles and an overestimation at small emission angles.These comparisons together with our previous results on the comparison of REELS/EPES spectra for other materials[21–23,37]demonstrate that this MC model of surface excitation should be correct.Our MC simulation method of surface excitation dif f ers largely from other MC simulations in that,not only the inelastic scattering cross section is position dependent but the details of surface excitation in sampling individual inelastic scattering events are also included.All these issues become more important for surface excitation at low energies.

As shown above,there is a considerable dif f erence between simulated elastic peak intensity by including surface and excluding surface excitations especially at low energy below 2 keV.The deviation is due to the surface excitation in MC simulations,which can be employed to determine the quantitative information of surface excitation in EPES where the trajectories of signal electrons are generally rather complex than V-type trajectory.According to this,the previous divided SEPs,i.e. incident SEP and escaping SEP,for estimation of the surface excitation information when electrons are incident onto or escaped from sample surface is no longer suitable in EPES.The total SEP def i nition will be more appropriate especially for low energy electrons.

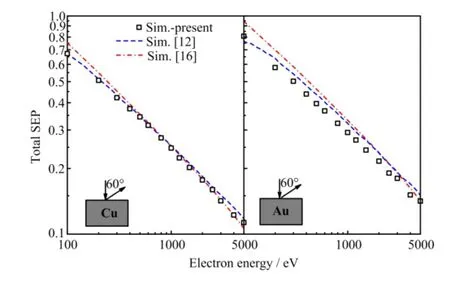

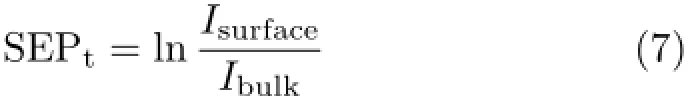

As surface excitation reduces the intensity of the elastic peak by a factor of exp(-SEPt),the total SEP can be calculated by

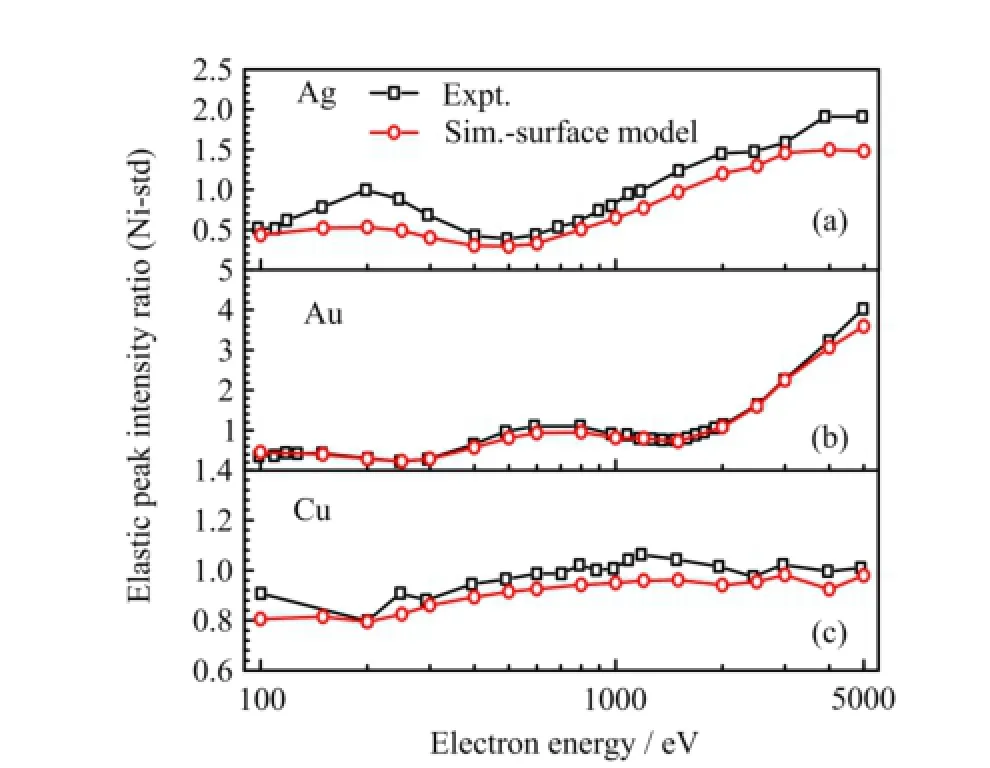

FIG.4 Comparison of total SEPs as a function of electron energy with the other results from Refs.[12,16]for Cu and Au.

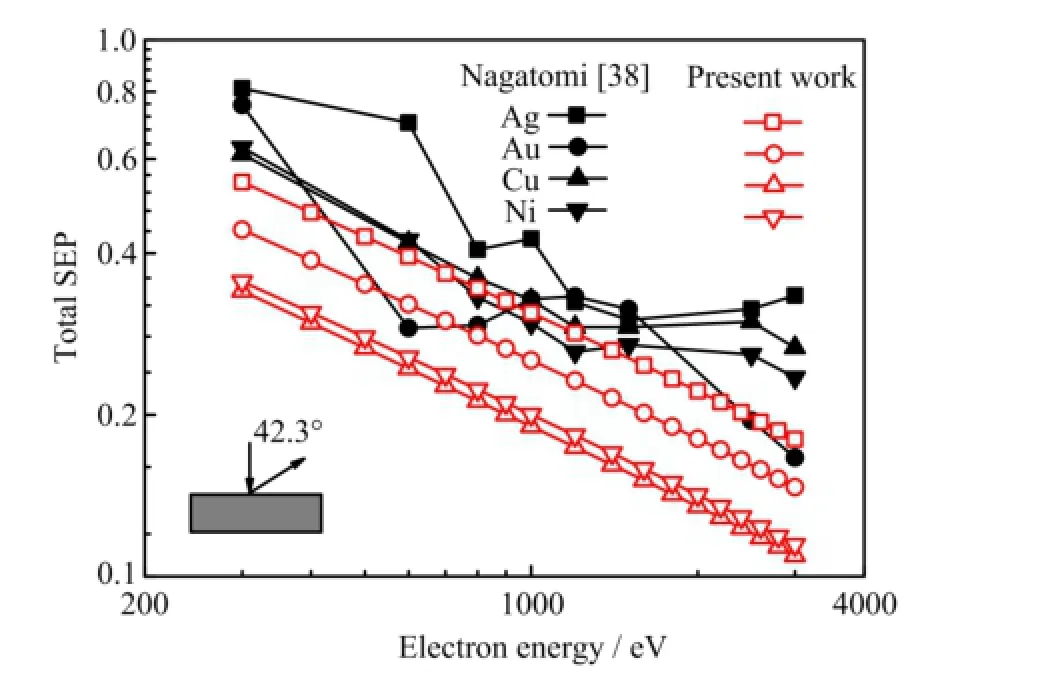

FIG.5 Comparisons on the energy dependence of SEPbetween the present calculation and the experimental results of Nagatomi et al.[38]measured by a CMA with a Faraday cup.

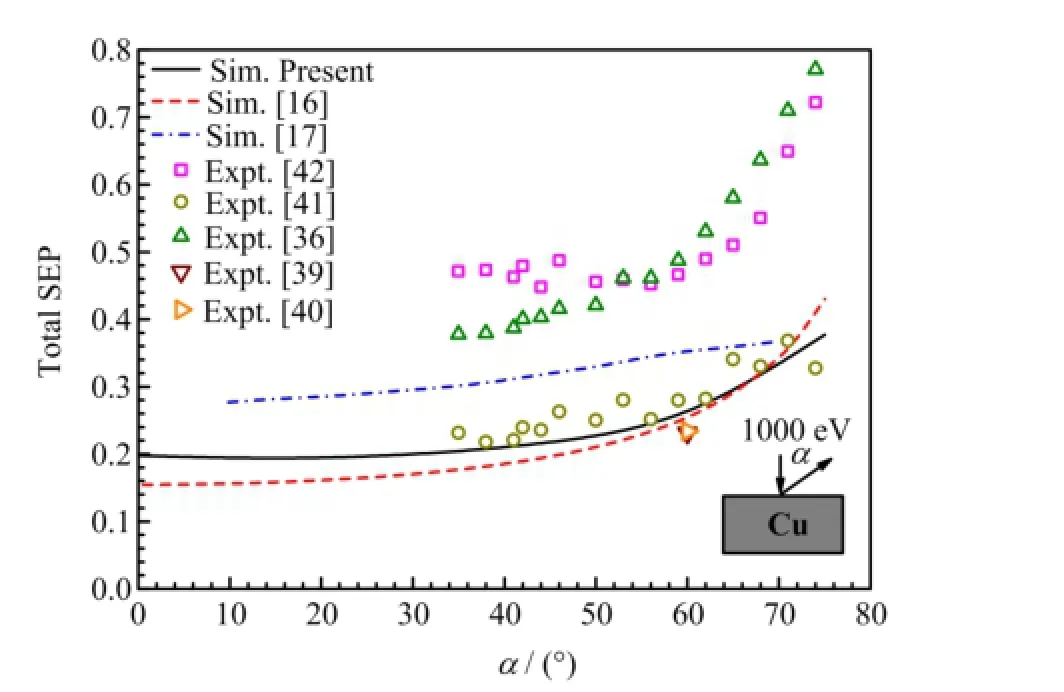

FIG.6 Comparison on the emission angular dependence of SEP for 1 keV normal incident electrons escaping from Cu surfaces between the present work,Pauly and Tougaard[17], Werner et al.[39–41],Jablonski and Zemek[36],Gergely et al.[42],and Da et al.[16].

where Isurfaceis the elastic peak intensity obtained with our surface model MC simulation,and Ibulkis the elastic peak intensity obtained with bulk model MC simulation.It is obviously that present SEP calculation method should be a more proper way to quantitatively estimate the surface excitation including the inf l uence of elastic collision in EPES,due to the employment of more realistic electron trajectories instead of simple V-type trajectory.

Figure 4 shows a comparison on the calculated total SEP as a function of electron energy for Au and Cu between present simulation results and the previous theoretical data by Salma et al.[12]and Da et al.[16], which are calculated from the integration of dif f erential surface excitation probability for both vacuum and solid sides,by the quantum mechanical approach and semi-classical approach,respectively.All these SEP decreases with an increasing electron energy because the time spent in the surface region is decreased.The dif f erence between our present results and previous theoretical results is due to the inf l uence of the elastic scattering in EPES,i.e.the previous studies have neglected elastic scattering ef f ect while the present work has taken into account of electron elastic scattering by MC simulation.It is found that elastic collision has weak inf l uence on SEP in high energy region and,however,strong inf l uence in low energy region,because the low energy electrons suf f er more elastic collisions by larger elastic scattering cross sections.Comparisons of total SEPs for Au,Cu and Ni with experimental results of Nagatomi [38]are shown in Fig.5.The SEPs in Nagatomi’s work are determined from absolute measured REELS spectra according to Landau theory.Due to the dif f erent def i nitions of SEP,present results are smaller than experimental values in most cases but our relative SEP results for dif f erent materials more or less match with the sequence measured by Nagatomi et al.[38].

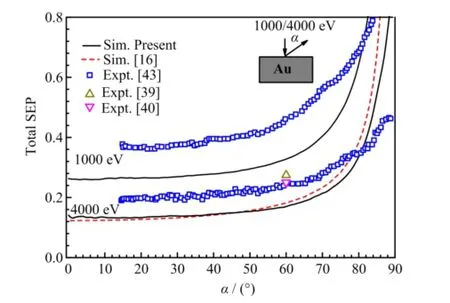

In order to get further information about the inf l uence of elastic scattering on surface excitation in EPES, Fig.6 shows a comparison of SEP among present results, previous theoretical results by Da et al.[16],Pauly and Tougaard[17]based on the V-type trajectory approximation as well as experimental results[36,39–42]. Because the time spent in the surface region is lengthened,all the SEP results increase with crossing angle increasing.There are considerable deviations among the calculated results due to the dif f erent treatments to elastic scattering ef f ect.It is found that the discrepancy between Pauly and Tougaard’s results and Da et al.’s results is larger for small emission angles,while the present results are in between;the increasing trend of these three results with angle are also quite dif f erent for large emission angles.As we mentioned that the pre-vious theoretical results by Da et al.were calculated from an integration procedure under the assumption that electrons cross the surface from negative inf i nity to positive inf i nity while the signal electrons in EPES are backscattered from sample within a very small probed depth especially for low energy electrons by multiple elastic scattering.The SEP calculated by Pauly and Tougaard[17]employed V-type trajectory assumption, which means the collected signal electrons only suf f er elastic scattering once.In order to calculate SEP more precisely,it is reasonable to use a more realistic situation,where the electron trajectories are determined from Mott’s elastic scattering cross section.It is found that our present results based on MC simulation lie between the Da’s and Pauly’s results and give the best trends when the emission angle increase.On the other hand,by comparison with experimental data it is found that the present result is close to Werner’s data[41], while quite dif f erent from Jablonski’s[36]and Gergely’s results[42],where the last two ones are based on the same set of experimental angular-resolved spectra.Figure 7 shows a similar comparison of SEP for Au and for normally incident electrons of 1 and 4 keV.It is obviously that these calculated results of Au have the similar behavior;however,there is a signif i cant deviation from experiment by Werner[43]due to the variations between dif f erent measurements and dif f erence in definition of SEP.But,alternative experimental data for 1 keV from Werner’s work[39,40]given in Fig.7 indicate opposite variation with present calculation;the signif i cant dif f erence up to 80%between these experimental data can be found even from the same group. Neglecting the absolute values,present results give the similar trends with experiments both for 1 and 4 keV. The discrepancy between present results and calculations by Da et al.[16]is due to the elastic scattering ef f ect.It is found that due to lacking of elastic scattering in Da’s results,there is a general tendency of underestimation at small angles and overestimation at large angles.Furthermore,this discrepancy between the present results and those of Da et al.is larger for primary electron energy of 1 keV than that of 4 keV via a more important role of elastic scattering in EPES at lower energy.

FIG.7 Comparison on the emission angular dependence of the SEP for normally incident electrons of 1 and 4 keV escaping from Au surfaces between the present work,Werner et al.[39,40,43],and Da et al.[16].

IV.CONCLUSION

A good agreement has been obtained on the elastic peak intensity and angle-resolved elastic peak electron intensity between experimental data and present MC simulation results including surface excitation for several metals,which conf i rms that our MC simulation method is reasonable.Based on the elastic peak intensity by including or excluding surface excitation, the total SEP for EPES were def i ned and calculated. This total SEP def i nition is more suitable for estimating the surface excitation in EPES by including the inf l uence of elastic scattering on the determination of SEP. Available theoretical and experimental data for the SEP based on dif f erent def i nitions were compared with our present calculations,and reasonable agreement is found between our results and some experimental data.From these comparisons,present MC-based method may provide the better SEP data than the existing theoretical methods.

V.ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China(No.11274288 and No.11574289).We thank the Supercomputing Center of USTC for support in performing parallel computations.

[1]G.Gergely,Prog.Surf.Sci.71,31(2002).

[2]C.J.Powell and A.Jablonski,J.Phys.Chem.Ref.Data 28,19(1999).

[3]S.Tanuma,S.Ichimura,and K.Goto,Surf.Interface Anal.30,212(2000).

[4]A.Dubus,A.Jablonski,and S.Tougaard,Prog.Surf. Sci.63,135(2000).

[5]W.de la Cruz and F.Yubero,Surf.Interface Anal.39, 460(2007).

[6]K.Olejnik,J.Zemek,and W.S.M.Werner,Surf.Sci. 595,212(2005).

[7]F.Yubero and S.Tougaard,Phys.Rev.B 46,2486 (1992).

[8]A.C.Simonsen,F.Yubero,and S.Tougaard,Phys. Rev.B 56,1612(1997).

[9]J.Zemek,P.Jiricek,B.Lesiak,and A.Jablonski,Surf. Sci.562,92(2004).

[10]C.J.Tung,Y.F.Chen,C.M.Kwei,and T.L.Chou, Phys.Rev.B 49,16684(1994).

[11]Y.F.Chen and C.M.Kwei,Surf.Sci.364,131(1996).

[12]K.Salma,Z.J.Ding,H.M.Li,and Z.M.Zhang,Surf. Sci.600,1526(2006).

[13]C.M.Kwei,S.J.Hwang,Y.C.Li,and C.J.Tung,J. Appl.Phys.93,9130(2003).

[14]Y.C.Li,Y.H.Tu,C.M.Kwei,and C.J.Tung,Surf. Sci.589,67(2005).

[15]R.H.Ritchie,Phys.Rev.106,874(1957).

[16]B.Da,Y.Sun,S.F.Mao,and Z.J.Ding,Surf.Interface Anal.45,773(2013).

[17]N.Pauly and S.Tougaard,Surf.Sci.601,5611(2007).

[18]N.Pauly,M.Novak,A.Dubus,and S.Tougaard,Surf. Interface Anal.44,1147(2012).

[19]S.Tougaard and F.Yubero,Surf.Interface Anal.36, 824(2004).

[20]F.Yubero and S.Tougaard,Phys.Rev.B 46,2486 (1992).

[21]B.Da,S.F.Mao,and Z.J.Ding,J.Phys.:Condens. Matter 23,395003(2011).

[22]B.Da,S.F.Mao,G.H.Zhang,X.P.Wang,and Z.J. Ding,J.Appl.Phys.112,034310(2012).

[23]B.Da,S.F.Mao,G.H.Zhang,X.P.Wang,and Z.J. Ding,Surf.Interface Anal.44,647(2012).

[24]N.F.Mott,Proc.Roy.Soc.London Ser.A 124,425 (1929).

[25]Y.Yamazaki,PhD Thesis,Osaka University,(1977).

[26]R.A.Bonham and T.G.Strand,J.Chem.Phys.39, 2200(1963).

[27]R.H.Ritchie and A.L.Marusak,Surf.Sci.4,234 (1966).

[28]F.Garcia-Moliner and F.Flores,Introduction to the Theory of Solid Surfaces,Cambridge:Cambridge University,(1979).

[29]B.Gumhalter,Prog.Surf.Sci.15,1(1984).

[30]R.H.Ritchie,A.Howie,P.M.Echenique,G.J.Basbas, T.L.Ferrelland,and J.C.Ashley,Scanning Microsc. Suppl.4,45(1990).

[31]S.Shindo,Solid State Phenom.28/29,103(1992).

[32]Z.J.Ding and R.Shimizu,Phys.Rev.B 61,14128 (2000).

[33]Z.J.Ding,J.Phys.:Condens.Matter 10,1733(1998).

[34]Z.J.Ding,H.M.Li,Q.R.Pu,and Z.M.Zhang,Phys. Rev.B 66,085411(2002).

[35]S.Tanuma,T.Shiratori,T.Kimura,K.Goto,S. Ichimura,and C.J.Powell,Surf.Interface Anal.37, 833(2005).

[36]A.Jablonski and J.Zemek,Surf.Sci.601,3409(2007).

[37]B.Da,S.F.Mao,Y.Sun,and Z.J.Ding,e-J.Surf.Sci. Nanotech.10,441(2012).

[38]T.Nagatomi,S.Tanuma,and K.Goto,Surf.Interface Anal.42,1537(2010).

[39]W.S.M.Werner,W.Smekal,C.Tomastik,and H. Stori,Surf.Sci.486,L461(2001).

[40]W.S.M.Werner,Surf.Interf.Anal.35,347(2003).

[41]W.S.M.Werner,L.Kover,S.Egri,J.Toth,and D. Varga,Surf.Sci.585,85(2005).

[42]G.Gergely,S.Gurban,M.Menyhard,A.Jablonski, J.Zemek,and K.Goto,Surf.Interface Anal.4,1365 (2011).

[43]W.S.M.Werner,W.Smekal,F.Salvat-Pujol,Z.Halavani,S.Pf l eger,J.Rastl,and C.Eisenmenger-Sittner, Appl.Phys.Lett.98,193111(2011).

?Author to whom correspondence should be addressed.E-mail: zjding@ustc.edu.cn

10.1063/1674-0068/30/cjcp1607146

CHINESE JOURNAL OF CHEMICAL PHYSICS2017年1期

CHINESE JOURNAL OF CHEMICAL PHYSICS2017年1期

- CHINESE JOURNAL OF CHEMICAL PHYSICS的其它文章

- Chinese Abstracts(中文摘要)

- Real-Time Observation of Pyoverdine Dissolving Ferric Hydroxide

- Electrochemical Preparation of Polypyrrole/Graphene Films on Titanium Mesh as Active Materials for Supercapacitors

- Preparation of Li4Ti5O12Microspheres with a Pure Cr2O3Coating Layer and its Ef f ect for Lithium Storage

- Narrow Band Gap and Room-temperature Ferromagnetism in KNb1-xFexO3-δ

- Catalytic Performance of Graphite Oxide Supported Au Nanoparticles in Aerobic Oxidation of Benzyl Alcohol:Support Ef f ect