Optimized growth of compensated ferrimagnetic insulator Gd3Fe5O12 with a perpendicular magnetic anisotropy?

Heng-An Zhou(周恒安),Li Cai(蔡立),Teng Xu(許騰),Yonggang Zhao(趙永剛),and Wanjun Jiang(江萬軍),?

1State Key Laboratory of Low-Dimensional Quantum Physics and Department of Physics,Tsinghua University,Beijing 100084,China

2Frontier Science Center for Quantum Information,Tsinghua University,Beijing 100084,China

Keywords:ferrimagnet,perpendicular magnetic anisotropy,ferrite and garnet devices,crystal growth

1.Introduction

Rare earth iron garnet(ReIG)of composition Re3Fe5O12is one of the most interesting material systems which has continuously attracted attention in the magnetism community[1–4]for storage,[5–9]microwave devices,[10–13]oscillators,[14,15]waveguides,[16–18]magneto-optical isolators,[19–21]spin current generator[22–25]and magnonic devices.[26–30]Very recently,ReIGs with a perpendicular magnetic anisotropy(PMA)appear as a popular material system in the field of spin-orbitronics.[31–35]Particularly,the electrical manipulation of perpendicular magnetization vectors[7,36,37]and the high-speed domain wall(DW)motion,[3,38–40]both enabled by the pure spin currents(in proximity with heavy metal Pt and/or W layers)have been successfully demonstrated.For examples,motion of DW at velocities of 750 m/s[3]and even above 4000 m/s,[40]was recently observed.

Through replacing a nonmagnetic Re element(Y,for example)by the other Re elements with large magnetic moments(Gd,[41,42]Eu,[43]Ho,[44,45]Tb,[46,47]and Dy[48,49]in particular),additional source of magnetism,together with many intriguing properties are introduced.[50–55]Using Gd3Fe5O12(GdIG)as an example,it contains three magnetic sublattices,[56,57]the a-site Fe3+ions octahedrally coordinated with the surrounding O2?ions,the d-site Fe3+ions tetrahedrally coordinated with the O2?ions,and the c-site Gd3+ions dodecahedrally coordinated with the O2?ions.[4]The moments of the a-site Fe3+ions are antiferromagnetically coupled to the moments of the d-site Fe3+ions,which also exhibit a weak ferromagnetic coupling to the moments of the c-site Gd3+ions.Through varying temperatures,the net magnetic moments of the Fe3+ions and the Gd3+ions can be fully compensated,manifesting as a magnetization compensation temperature(TM).[56–58]On the other hand,due to the slightly different g factors of the Fe and Gd elements,the net(spin/orbit)angular moments can also be fully compensated,marked as an angular moment compensation temperature(TA).These two characteristic temperatures of the GdIG films,resembling as the equivalent properties of antiferromagnets,have recently brought new exciting opportunities for spintronics.[59,60]The most recently reported ultrafast DW motion[3,38–40]and strong magnon–phonon coupling[61–63]are just a few representative examples.It should be mentioned here that among all ReIGs,GdIG is particularly promising as it exhibits the highest(near room temperature)compensation temperature,[56,57]which promises its potential for room temperature ultrafast spintronics.

Note that pulsed laser deposition(PLD)is frequently used for synthesizing high quality garnet films,and complex oxides in general.[43,64,65]The size of sample is however,typically limited to a few millimeters.[66,67]Recently,off-axis magnetron sputtering has been used for growing garnet films with high quality,[68,69]implying that magnetron sputtering is also suitable for growing large area garnet films with high uniformity.However,a systematic investigation of the growth condition and annealing condition on the properties in GdIG is still lacking.

Towards spin-orbitronic applications,GdIG(or ReIG in general)thin films with a PMA at room temperature are demanded.To obtain a GdIG film with a PMA,a tensile strain arising from the lattice mismatch between the GdIG film and the substrate should be carefully examined.[70–72]Since the lattice constant of GdIG is 1.2471 nm,[56–58]we will use single crystalline Gd3Sc2Ga3O12(GSGG)substrate with a lattice constant 1.2554 nm,which could provide a maximum tensile strain that can be beneficial for stabilizing PMA.Note that different growth conditions,including the growth temperature,the annealing temperature/time,the lattice mismatch between substrates and films(and the resulting strain),not only affect the growth dynamics of GdIG films,but also substantially alter the magnetic properties.In this study,we will systematically study the surface morphological,the structural,and the magnetic properties of GdIG films grown under different conditions,aiming for achieving a room temperature PMA and a smooth surface,together with a low effective magnetic damping parameter.

Following this motivation,the evolution of PMA,the surface roughness,and the magnetization compensation of GdIG films will be investigated through changing(a)the annealing temperature,(b)the growth temperature,(c)the substrate preannealing temperature,(d)the annealing duration,and(e)the lattice mismatch between different substrates.In the very end,we will quantify(f)the evolution of magnetization compensation temperature as a function of growth parameters and(g)the effective Gilbert damping parameter in the GdIG/Pt bilayer.

2.Results and analyses

GdIG thin films with a fixed(nominal)thickness of 15 nm were deposited on top of various(111)-oriented single crystalline substrates by using a radio-frequency(RF)magnetron sputtering technique,from a commercial target with a nominal composition of Gd3Fe5O12by using an ultrahigh vacuum(UHV)sputtering system(AJA-Orion 8).The base pressure of the main chamber is better than 3×10?8Torr.During the deposition,the argon pressure was fixed at 3 mTorr,the deposition rate of GdIG is calibrated to be 0.6 nm/min.An in-situ annealing process could be conducted in the sputtering chamber under a mixture of argon and oxygen environment,with an oxygen partial pressure of 20% of 1 mTorr.After annealing,all films were naturally cooled down to room temperature.

A Gd3Fe5O12target of nominal composition(99.99%)and various single crystalline substrates used in the present work were commercially available from Kejing,LTD(Hefei,China).X-ray diffraction(XRD)experiments were done by using a Smartlab x-ray diffractometer(Rigaku).Surface morphology was characterized by using a Bruker atomic force microscope(AFM).Magnetometry measurements were done by using a Quantum Design magnetic properties measurement system(MPMS).Transport measurements were done by using a Quantum Design physical properties measurement system(PPMS).All magnetometry,AFM,XRD,and spin pumping experiments were performed at room temperature,unless otherwise specified.

2.1.Annealing effects on the films grown at room temperature

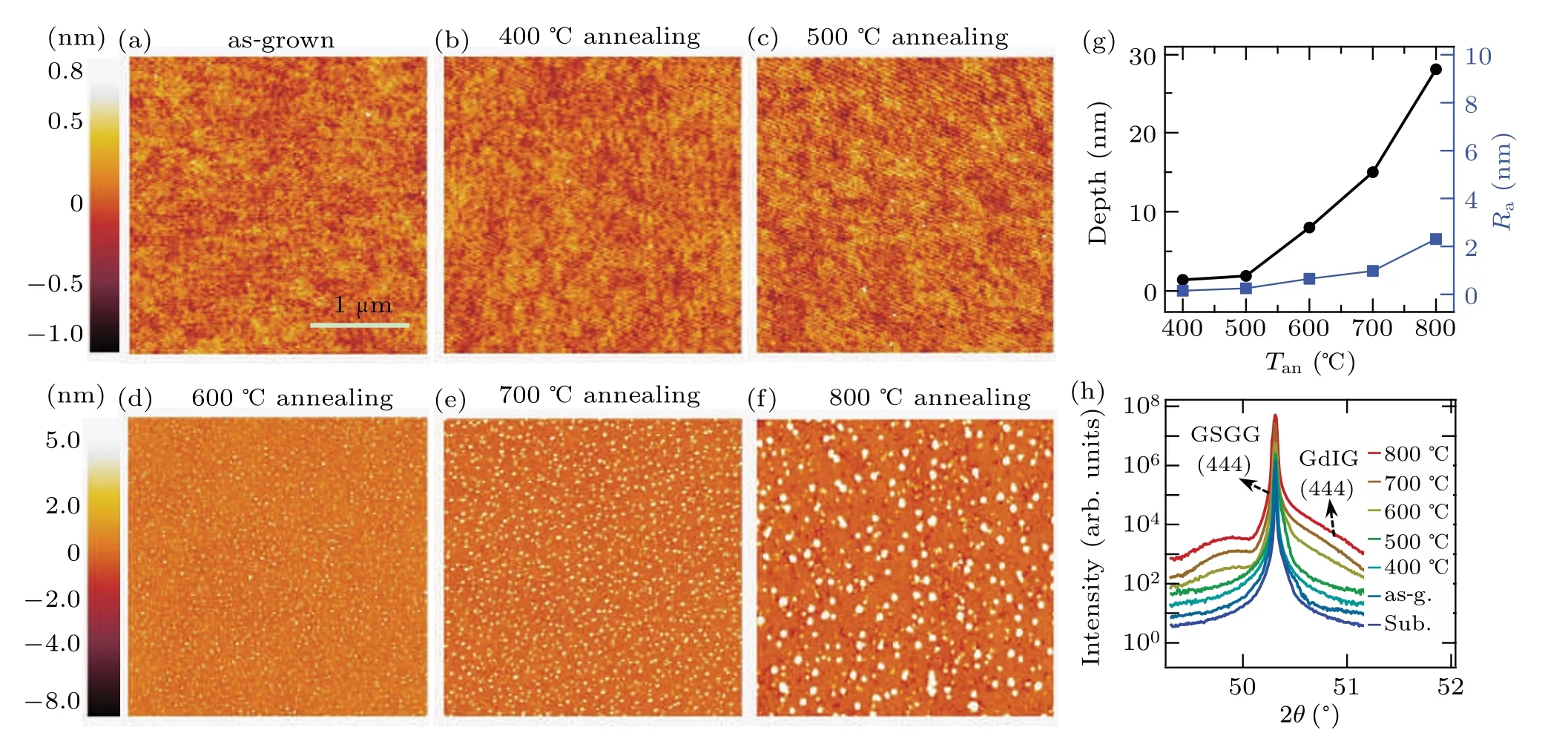

We first synthesized a series of GdIG films of fixed thickness 15 nm on the GSGG(111)-oriented single crystalline substrates at room temperature,which were subsequently annealed in-situ in the growth chamber under different annealing temperatures(Tan).Tanranges from 400°C to 800°C in 100°C steps,with a fixed duration of 3 hours.Figures 1(a)–1(f)show the corresponding perpendicular magnetization hysteresis loops(M–Hz)of the as-grown GdIG film and the GdIG films annealed at different Tan.The as-grown GdIG film does not show any measurable magnetic signal.For Tan≥600°C,both magnetic signals and square-like hysteresis loops appear,which confirm the presence of PMA of the prepared GdIG films.The evolution of the saturation magnetization(Ms)and the coercivity(Hc),as a function of Tan,are summarized in Fig.1(g).It is clear that Msstarts to increase from Tan=500°C,which reaches a constant value(Ms=25 emu/cc)when Tan≥600°C.The corresponding Hcincreases following the increase of Tan.

To correlate the magnetic properties with the film quality,we further studied the surface morphology and the crystal structure of these GdIG films.The evolution of the surface roughness(obtained by performing AFM experiments)as a function of Tanis shown in Figs.2(a)–2(f).A smooth surface of the as-grown GdIG film and the film annealed at 400°C and 500°C with a roughness value around 0.15 nm(rms)can be seen.It is also noted that the grain size increases following the increase of Tan(≥600°C).Monotonic increases of the height depth(defined as the distance between the highest peak and lowest valley)and roughness(rms)as a function of Tanare further shown in Fig.2(g),which contribute to the enhancement of Hc.

Fig.1.(a)–(f)The magnetization hysteresis loops(M–Hz)of the as-grown GdIG film and the GdIG films that were annealed at different annealing temperatures(Tan).Magnetic fields were applied normal to the film plane(i.e.,along the z direction).(g)The evolution of the saturation magnetization(Ms)and coercivity(Hc)as a function of Tan.

Fig.2.(a)–(f)A series of AFM images for GdIG films.The increased grain sizes can be found with the increase of annealing temperature Tan.(g)The height depth and the surface roughness(rms)as a function of Tan.(h)The corresponding XRD spectra of GdIG films,in which diffraction peaks of the GSGG(444)crystal orientation can be seen,together with the GdIG(444)peak when Tan≥600 °C.

It has been previously mentioned that GdIG film with PMA is an ideal platform for spin–orbitronics.For the currentinduced spin–orbit torque(SOT)manipulation of the perpendicular magnetization or DW dynamics in the GdIG films,a very thin capping layer of heavy metals(~4 nm)with a strong spin–orbit interaction is typically required.For the annealed GdIG films with a PMA,a typical height depth is around 8 nm(Tan=600°C).Thus,a 4 nm heavy metal capping layer cannot ensure a full coverage of GdIG films,which prohibits a further SOT study in these films.

In order to probe the structural properties,we have performed XRD experiments.The x-ray spectra of GdIG films measured around the(444)diffraction peaks of the substrate are shown in Fig.2(h).It can be seen that the(444)diffraction peaks of the GdIG films are only visible when Tan≥600°C,which indicate the crystallization of GdIG films.The evolution of the film peak position with respect to the substrate peak position reveals an expected tensile strain from the substrate,which is also consistent with the occurrence of PMA.

2.2.Varying the growth temperature

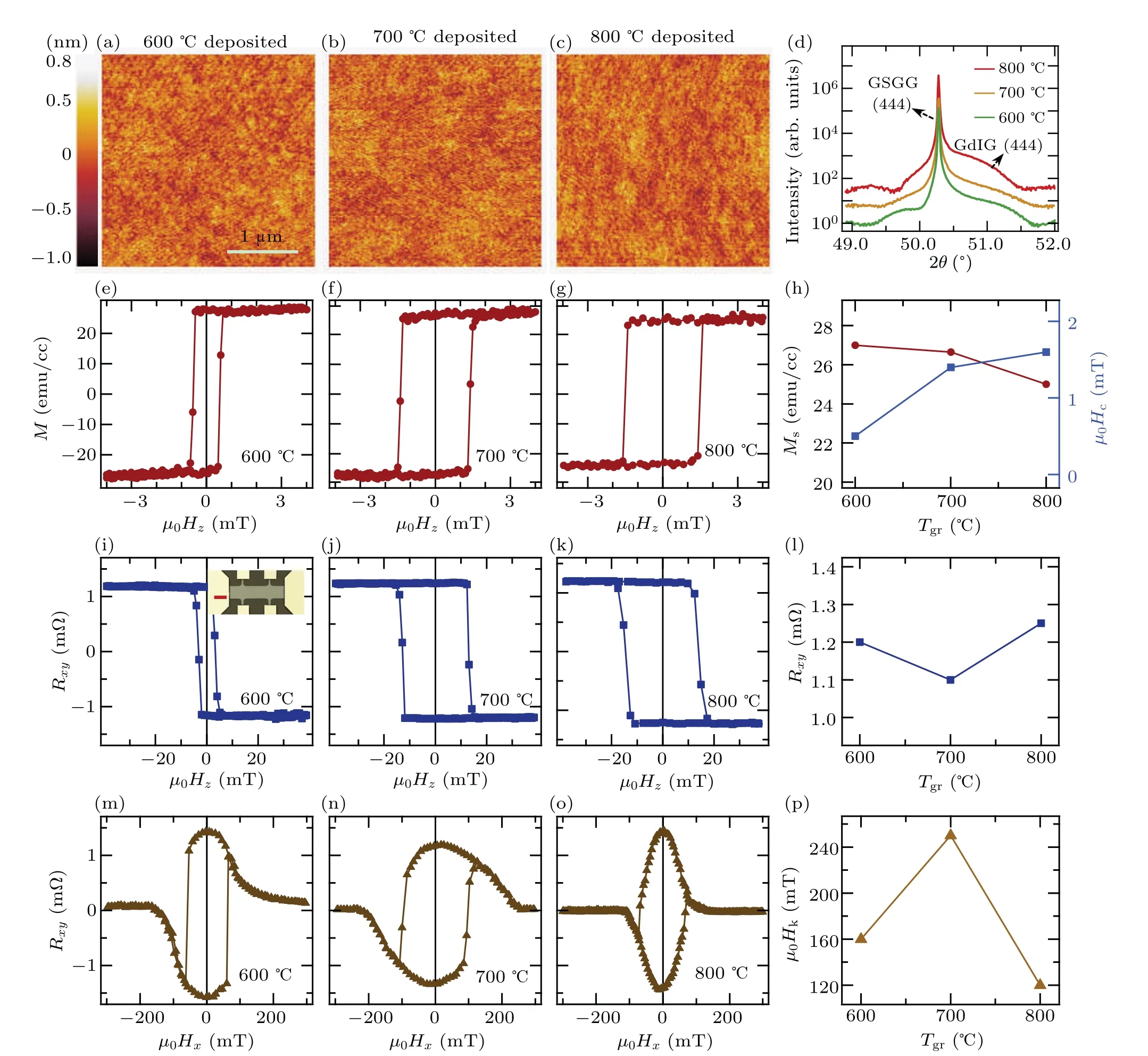

In the following,we will examine the influence of the growth temperature(Tgr)on the film quality.At a relative high growth temperature,atoms with sufficient kinetic energy could easily find the lattice matched location on the substrate,which could naturally give rise to a smoother surface of GdIG film,together with a strong PMA.Note that the growth dynamics by changing growth/annealing temperature(Tgr/Tan)could be different.In the former case,atoms could move to the corresponding lattice position(during growth)and form a highquality film.In the latter case,atoms in a grain are not able to move(after growth)between grains during annealing.

Fig.3.(a)–(c)TheAFM images of GdIG flimsgrown atdifferent temperatures(Tgr).(d)The XRDspectraof GdIG flimsdeposited at 600°C,700 °C,and800 °C,respectively.(e)–(g)Thecorresponding M–Hz loops.(h)TheevolutionofMs and Hc as a function of Tgr.(i)–(k)The SMR measured intheHallgeometryinGdIG/Pt(15 nm/4 nm)bilayers.Shown intheinsetis an opticalimage ofHall bardevice.The scale bar is 20μm.(l)The saturated as function of Tgr.(m)–(o)The measured in a planar Hall geometry.(p)The effective feild of PMA(μ0Hk)as a function of Tgr.

Since our previous experiments suggested that GdIG films can crystallize at 600°C(during the annealing),and meanwhile,exhibit PMA,we will explore the properties of the GdIG films grown at 600°C,700°C,and 800°C respectively.After deposition,an in situ annealing at the corresponding growth temperature for 3 hours was conducted.Figures 3(a)–3(c)are the AFM images of these three samples,in which no visible grains can be seen from the AFM images.The surfaces are very smooth with a roughness(rms)less than 0.19 nm,in stark contrast with the films grown at room temperature(Fig.2).The corresponding XRD spectra of the GdIG films show(444)diffraction peaks of both substrate and GdIG film,as shown in Fig.3(d).Intensity oscillations can also be observed,indicating a high-quality crystallinity and a smooth interface.

2.3.Varying the substrate preannealing temperature

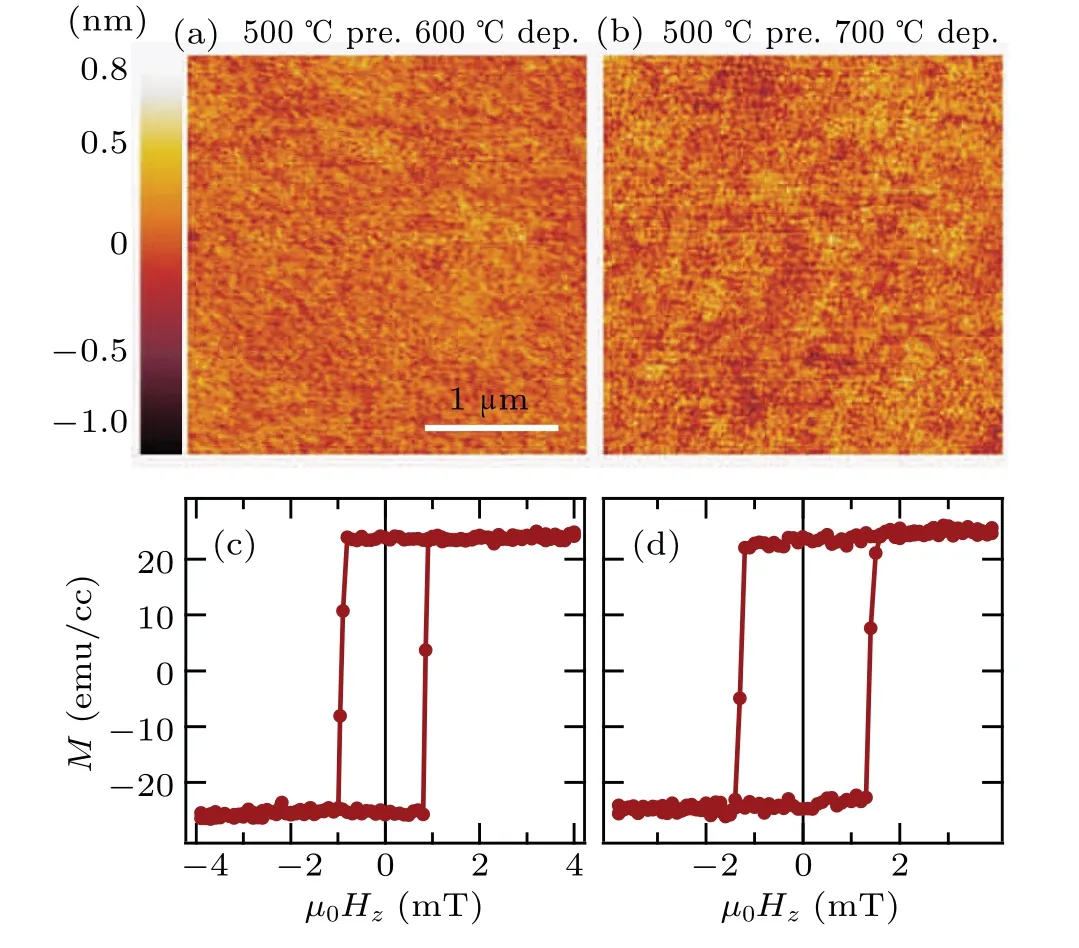

It is also known that the substrate quality could affect the magnetic and structural properties of films.We will subsequently examine whether a preannealing procedure on the aspurchased substrate could influence both the film roughness and the strength of PMA.These substrates were preannealed at 500°C for 0.5 hour before growth in vacuum,as most of adhesive carbides on the substrate will disappear at 500°C,which could likely give rise to a better film quality.After the preannealing process,we deposited GdIG films at 600°C and 700°C,respectively,which were subsequently followed by an in situ annealing at the corresponding growth temperature for 3 hours.The AFM images shown in Figs.4(a)and 4(b)indicate that both films exhibit very smooth surfaces with roughnesses(rms)of 0.17 nm and 0.18 nm,respectively.The magnetic measurements show that the M–Hzloops(Figs.4(c)and 4(d))remain the same as those of GdIG films which did not involve a substrate preannealing(Fig.3).These results indicate that preannealing of the as-purchased substrates is not essential,for which could not improve the quality of the GdIG films.

Fig.4.(a)and(b)AFM images of GdIG films grown on the preannealed substrates.Before the growth of GdIG,GSGG substrates were preannealed at 500 °C for 0.5 hour.The growth temperature of GdIG film is 600°C and 700°C,respectively.(c)and(d)M–Hz loops of GdIG films,which remain approximately the same as that of GdIG films grown on the as-purchased substrates(Fig.3).

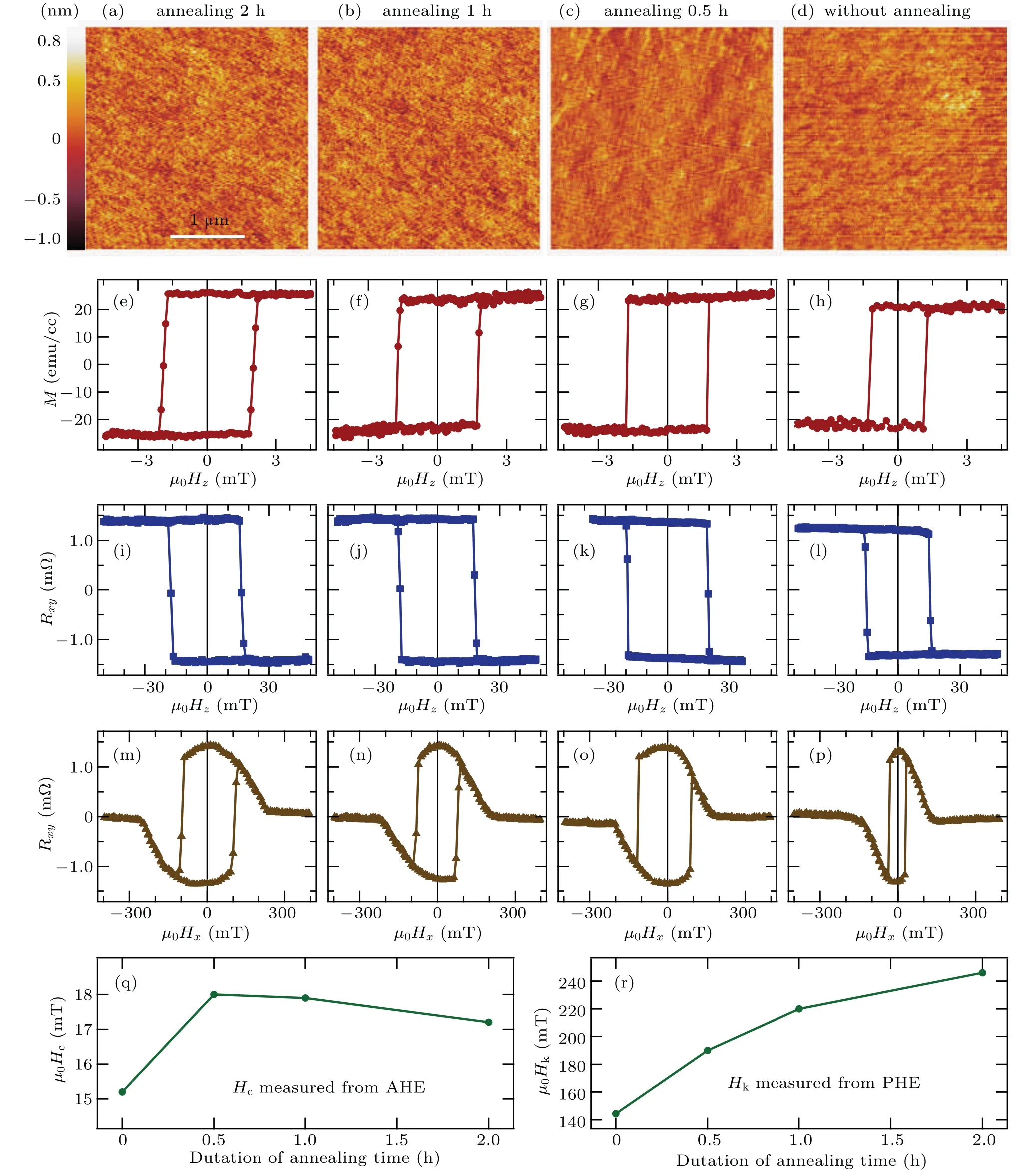

2.4.Varying the duration of annealing time

Fig.5.(a)and(b)The AFM images of GdIG films annealed at 700 °C for 2 hours,1 hour,0.2 hour,and 0 hour,respectively.(e)–(h)The M–Hz loops of GdIG films that were being annealed for different durations of time.(i)–(l)and(m)–(p)The corresponding AHE/PHE curves in GdIG/Pt bilayers.(q)and(r)The annealing duration dependent Hc and Hk,obtained from AHE and PHE measurements,respectively.

2.5.Varying substrates with different lattice constants

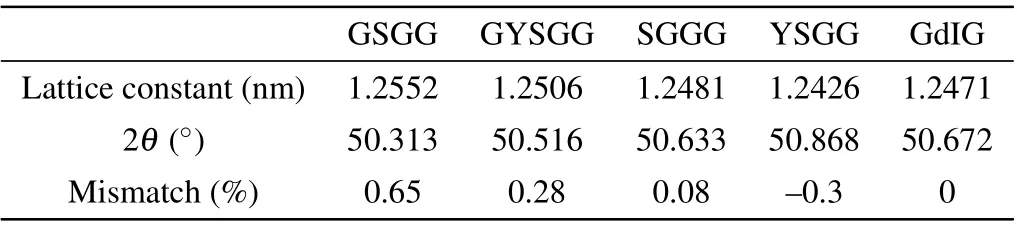

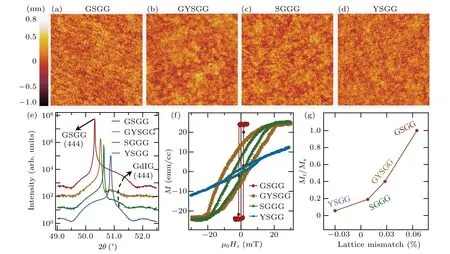

To elucidate the important role of the strain for stabilizing PMA in GdIG films,we will use different single crystalline garnet substrates with a continuous change of lattice constants. This is made possible by using commercially available garnet substrates,including Gd3Sc2Ga3O12(GSGG),Gd0.63Y2.37Sc2Ga3O12(GYSGG),Gd2.6Ca0.4Ga4.1Mg0.25Zr0.65O12(SGGG),and Y3Sc2Ga3O5(YSGG)(Kejing,LTD).The nominal lattice constants are 1.2554 nm,1.2507 nm,1.248 nm,and 1.2426 nm,respectively.These substrates thus provide an ideal platform for examining the evolution of PMA from the tensile strain to the compressive strain.The GdIG films were all deposited at 700°C,and followed by an in situ annealing at 700°C for 3 hours.

Figures 6(a)–6(d)are the AFM images of GdIG films,all of which exhibit a roughness around 0.17 nm(rms),a result similar to the previous experiments(Figs.3 and 4).In order to characterize the quality of the GdIG films and calculate the lattice constant of the used substrates,we also performed XRD experiments.Based on the Bragg’s law,the lattice constant can be calculated.The positions of(444)peaks lead the lattice constants of GSGG,GYSGG,SGGG,and YSGG to be determined as 1.2552 nm,1.2506 nm,1.2481 nm,and 1.2426 nm,respectively.These calculated lattice constants are tabulated in Table 1.Additionally,the Laue fringes on both sides of the(444)peak can be observed from the XRD spectra,as shown in Fig.6(e).

While both the crystal structure and the surface morphology are very high-quality,the magnetic properties of the GdIG films grown on these different substrates are however,quite different.Figure 6(f)shows the M–Hzloops,which clearly evidence a substrate dependence of magnetic properties.In particular,with a small lattice constant change of 1%between GSGG and YSGG substrates,the magnetic remanence ratio drastically changed from 100%to 5%,as shown in Fig.6(g).The resultant magnetic anisotropy,as reflected by the shape of M–Hzloops,changes accordingly.These results indicate the important role of lattice mismatch for stabilizing PMA in GdIG films.

Table 1.Detailed material specific parameters of substrates and GdIG films.

Fig.6.(a)–(d)The AFM images of GdIG films deposited on top of different single crystalline substrates.(e)The corresponding XRD spectra of GdIG films.(f)The associated M–Hz loops.(g)The lattice mismatch dependent magnetic remanence ratio.

2.6.Evolution of magnetization compensation temperatures

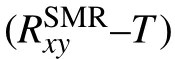

Fig.7.The–T curves measured in GdIG/Pt bilayer with Hz=1 T.Data is shifted(up and down)for clarity.The sudden jump of –T is identified as TM.

2.7.The Gilbert damping of GdIG

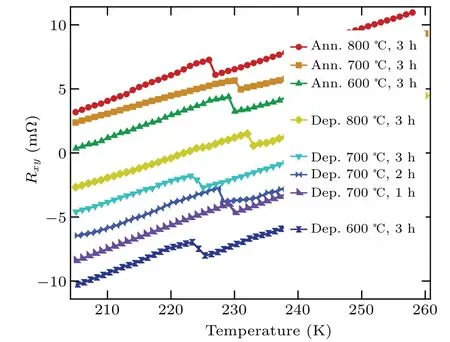

One of the unique motivations of studying the compensated ferrimagnetic insulator is the absence of conduction electrons,which leads to a low damping parameter that promises their usage in low power consumption spintronics.In the following,we will use a spin pumping technique[25,77]to determine the amplitude of effective damping parameterαeffin a GdIG/Pt bilayer deposited at 700°C and in situ annealed for 2 hours.In this experiment,we fabricated GdIG/Pt microstripes which were integrated with a co-planer waveguide(CPW),as shown in the inset to Fig.8(a).When a microwave current is fed into the CPW,the accompanied oscillating rf magnetic field drives the precession of magnetization of the GdIG films,which results in the pumping of spin current into the adjacent heavy metal Pt layer.An electrical voltage signal can be subsequently detected,as a result of the inverse spin Hall effect of the Pt layer.

Figure 8(a)shows the spin-pumping voltages measured at different microwave frequencies.During this measurement,the magnetic field HIPwas applied in plane with an angle 45°with respect to the GdIG/Pt microstripe.Each spectrum exhibits two symmetrical resonant peaks with an opposite sign,which evolve systematically as a function of the resonant frequency.The resonant linewidth can be obtained by using V=VspΔH2/[(H?Hr)2+ΔH2],where Vsp,ΔH,and Hrare the amplitudes of spin pumping voltage,linewidth,and resonant field,respectively.Through studying the dependence of the linewidth as a function of the microwave frequency,the effective damping parameter(αeff)can be estimated based on ΔH=ΔH0+αeffω/γ,as shown in Fig.8(b).Considering a gyromagnetic ratioγ=2.8 GHz/kOe,μ0ΔH0=8 mT,αeff=0.04±0.01 can be obtained.Specifically,theαeffof GdIG/Pt is bigger than that of YIG/Pt(1×10?4to 1×10?3).[25,78]The enhanced damping parameter may originate from the lattice mismatch between GdIG and substrate,or the induced noncollinear spin profile of the Fe3+sublattices due to the presence of the heavy Gd3+ions.[79,80]

Fig.8.(a)The resonant spectra measured at different microwave frequencies in the presence of in-pane magnetic fields HIP.Shown in the inset is an optical image of the device,in which GdIG/Pt microstripe is located between CPW.The scar bar is 50μm.The fitted spin-pumping signal is highlighted in red.(b)The evolution of resonant widths as a function of resonant frequency which can be linearly fitted by using ΔH=ΔH0+αeffω/γ.

3.Conclusion

In summary,we have systematically studied the surface morphology,the structural properties,and the magnetic properties of compensated ferrimagnetic insulator thin films of composition Gd3Fe5O12(GdIG).In particular,the influence of the annealing temperatures/durations,the growth temperatures,and the choice of substrates for ensuring both highquality growth and the presence of a perpendicular magnetic anisotropy(PMA)were studied.The GdIG films grown at room temperature and annealed at temperature higher than 600°C exhibit PMA,but a very rough surface.The surface roughness can be substantially improved by changing the growth temperature(≥600°C).And we have found that the strength of PMA reaches maximum when depositing GdIG at 700°C and following an in situ annealing for 2 hours at 700°C.Furthermore,the effect from the lattice mismatch(and from tensile strain to compressive strain)by choosing different single crystalline ReIG substrates was also examined.In the end,we have also quantified the effective magnetic damping parameter(αeff=0.04±0.01)through a spin pumping experiment in a GdIG/Pt microstripe.Through optimizing the growth conditions of GdIG films,our studies could provide useful information for synthesizing similar perpendicularly magnetized ReIG films and their heterostructures,which could be beneficial for developing the efficient compensated ferrimagnetic spintronics.

- Chinese Physics B的其它文章

- Multiple solutions and hysteresis in the flows driven by surface with antisymmetric velocity profile?

- Magnetization relaxation of uniaxial anisotropic ferromagnetic particles with linear reaction dynamics driven by DC/AC magnetic field?

- Influences of spin–orbit interaction on quantum speed limit and entanglement of spin qubits in coupled quantum dots

- Quantum multicast schemes of different quantum states via non-maximally entangled channels with multiparty involvement?

- Magnetic and electronic properties of two-dimensional metal-organic frameworks TM3(C2NH)12*

- Preparation of a two-state mixture of ultracold fermionic atoms with balanced population subject to the unstable magnetic field?