Influence of shielding gas on the transfer behavior of droplets

Research Institute,Baoshan Iron & Steel Co.,Ltd.,Shanghai 201999,China

Abstract: High-speed photography is utilized to capture an image of the arc area during the welding process.The variation in arc shape and droplet transfer behavior is compared when employing shielding gases of different components and proportions (e.g.,80%Ar+20%CO2,85%Ar+10%CO2+5%O2,65%Ar+26.5%He+8%CO2+0.5%O2) using a φ1.2 mm welding wire under 360 A current.Furthermore,the effects of various shielding gas components on the stability of the welding process are discussed.It was determined that the addition of oxygen and helium changed the arc’s shape and the behavior of the droplet transfer,and the welding process stability increased.

Key words: GMAW; shielding gas; droplet transfer

1 Introduction

In the gas metal arc welding (GMAW) method,the welding wire is used as the electrode,which melts due to the arc’s significant heat,and becomes a droplet and transitions to the molten pool.The shielding gas is an essential influencing factor in GMAW.Studies have shown that the shielding gas affects the welding arc’s temperature distribution,the droplet transfer mode,and the molten pool and weld shapes.Moreover,the mechanical properties of the final welded joint are affected[1- 4].Every time the droplet falls from the end of the welding wire,the arc length changes intermittently during the welding process.Therefore,the droplet’s size,shape,and transition frequency determine the arc’s stability and affect the weld operability and quality[5].In order to study the influence of the shielding gas on the droplet transition process and provide gui-dance in gas selection,the typical binary,ternary,and quaternary gases are selected with different com-position ratios,and the welding process perfor-mance test is carried out to compare the varying influence.

2 Experimental procedure

The welding equipment includes a Fronius TranSteel 5000 gas shielded welding machine,and the photography apparatus is a PHANTOM VEO710L high-speed camera.The welding material is an ultra-high-strength solid welding wire with a diameter of 1.2 mm,and the mechanical properties of the deposited metal are listed in Table 1.The setup of the test platform is shown in Fig.1.

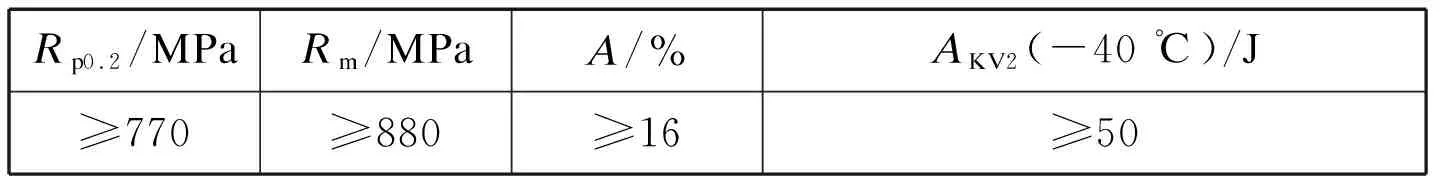

Table 1 Mechanical properties of the deposited metal (ultra-high-strength welding wire)

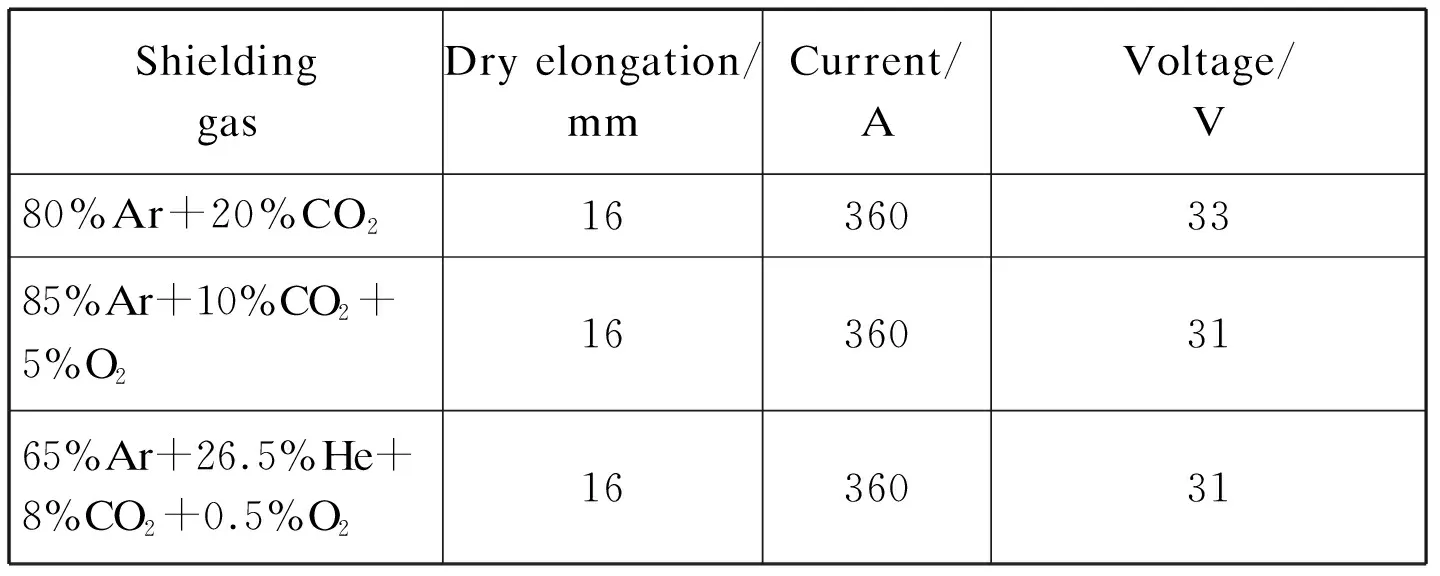

The dry elongation of the welding wire is fixed,and the high-current parameter specification is used to perform the surfacing welding test at the flat welding position,and the shielding gas composition is varied to compare and study the impact of the shielding gas on the process stability.The dry elongation is set to 16 mm in the actual welding test,and the welding current is 360 A.The specific welding parameters are shown in Table 2.Additionally,the welding voltage varies due to the variation in the shielding gas.

Fig.1 The test platform

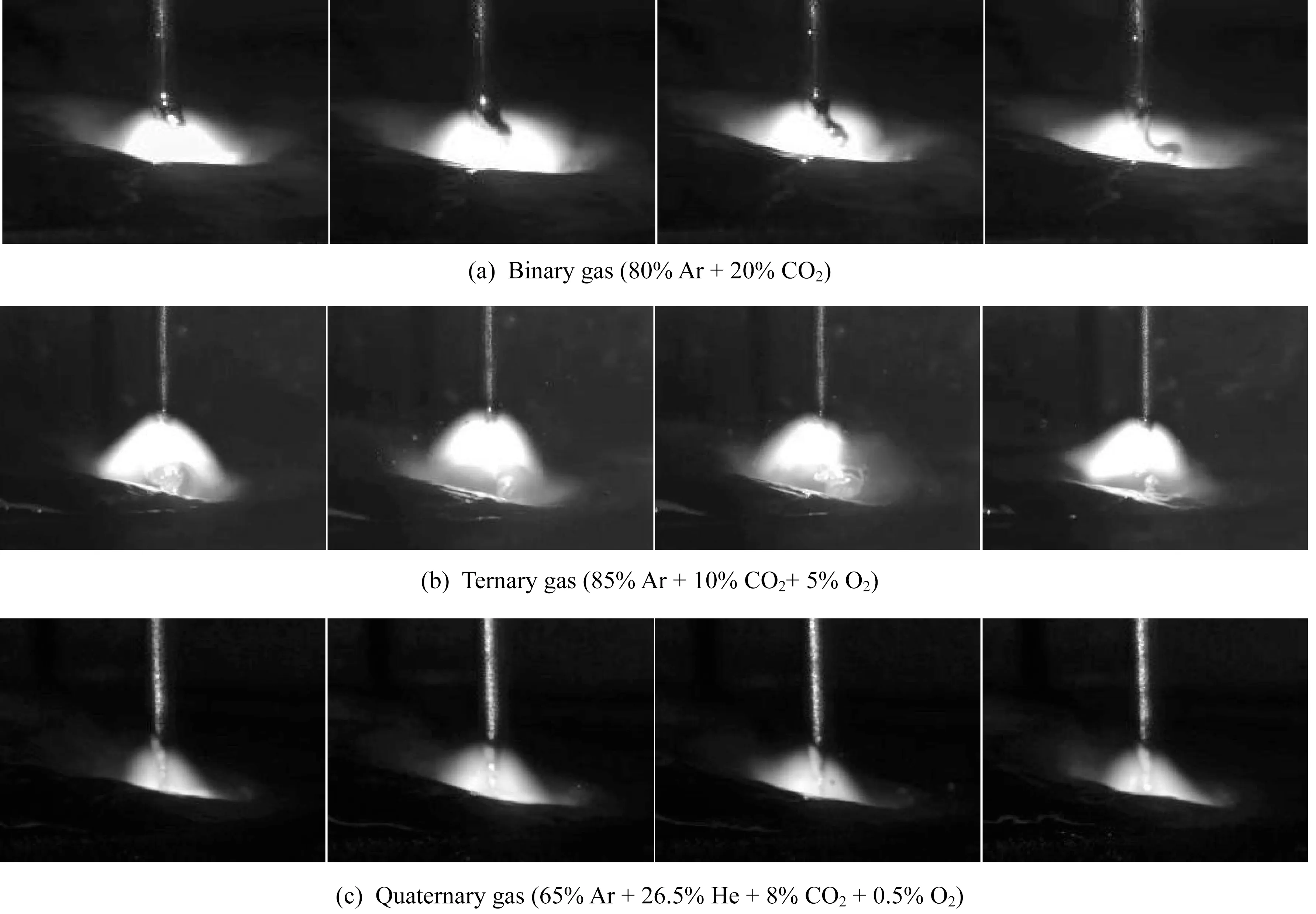

During the welding process,a high-speed camera was used to record the arc micro area image at 5 000 frames/s.The high-speed camera and the illumination laser are set on the same side.The screen can record the arc shape and droplet transition information based on the laser intensity and camera exposure settings.The welding process using different shielding gases is shown in Fig.2.

Table 2 Welding process parameters

Fig.2 High-speed photography images of welding process

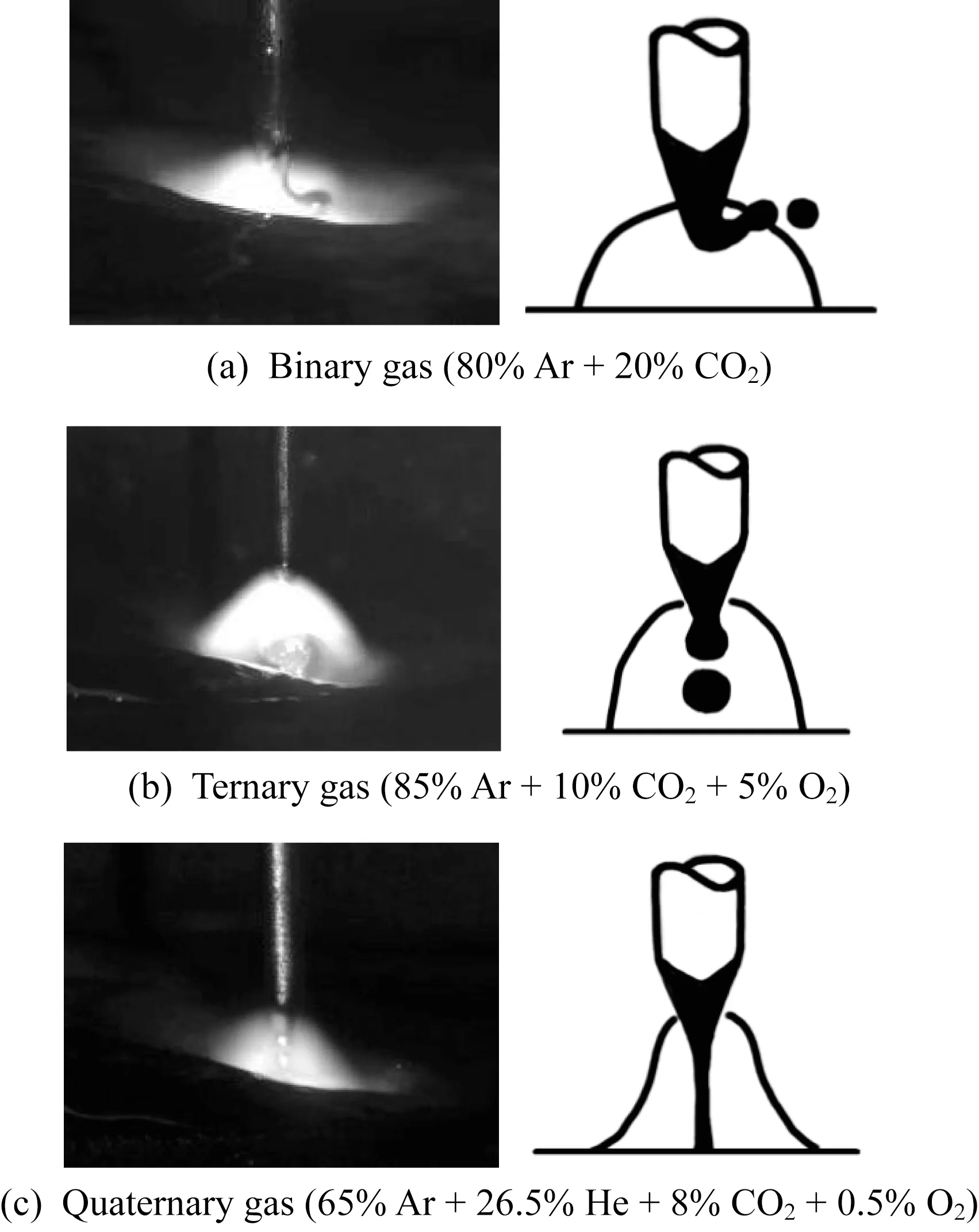

Fig.3 exhibits the observation and analysis of the welding process.The arc is semicircular as the binary gas is used,and the arc coverage is the widest.For the ternary gas,the arc is bell-shaped,and the arc height is the largest.When the quaternary gas is employed,the arc is broom-like and is the shortest and narrowest.From the perspective of droplet transfer mode,when using binary gas as a protective atmosphere for welding,the arc holds up the droplet after the welding wire is melted,and the droplet propagates up.Some droplets are transferred to the molten pool,and others are projected above the arc.When welding with ternary gas as a protective atmosphere,the droplets enlarge inside the arc after the welding wire is melted,forming droplets of different sizes,which drop from the end of the wire into the molten pool.The welding wire melts and transitions into the molten pool when using the quaternary gas.

Fig.3 Schematic diagrams of droplet transfer and arc shapes

3 Results and discussion

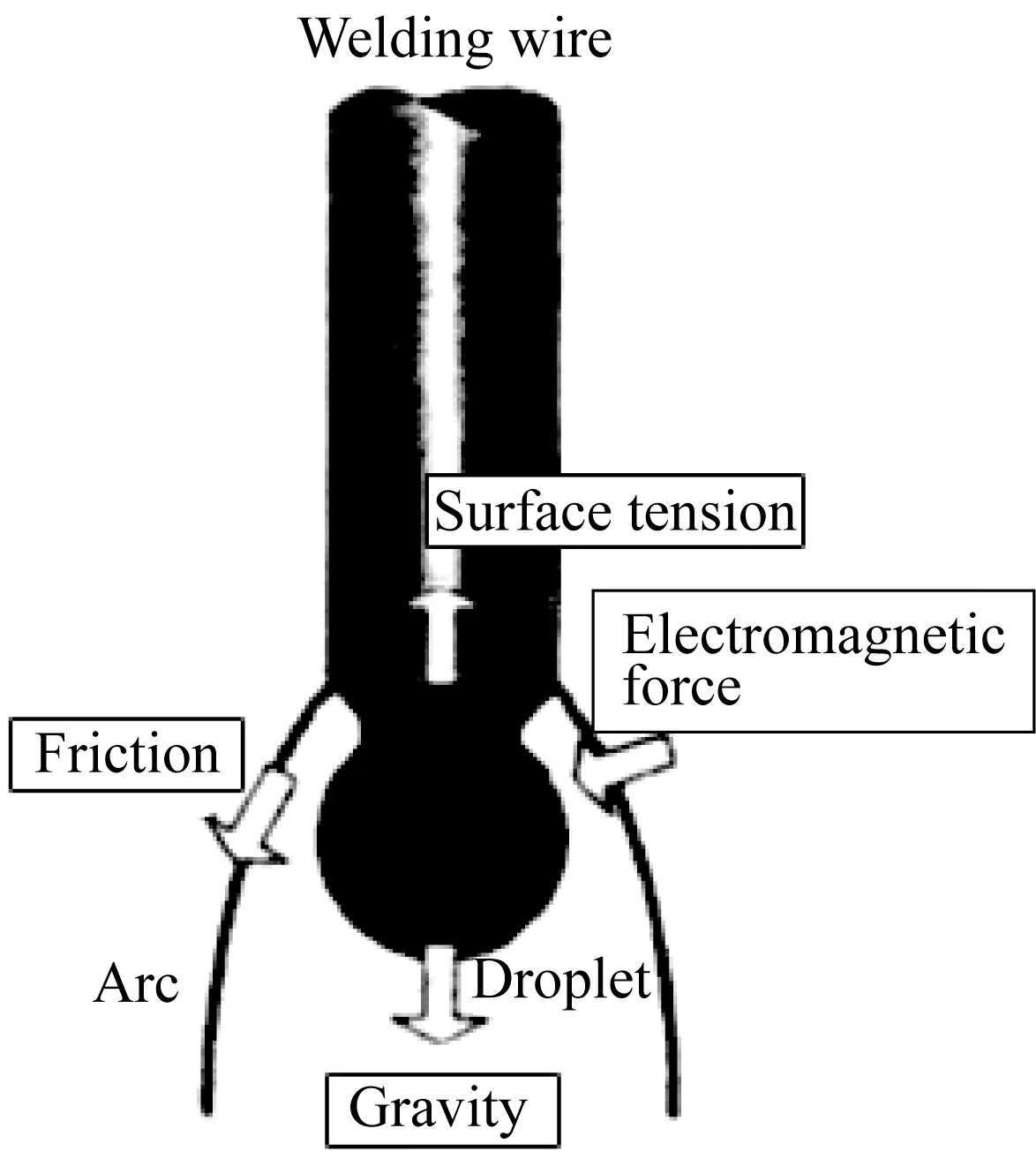

In the welding arc,the molten metal at the front end of the wire breaks away and transitions to the molten pool.The main forces acting on the arc are gravity,surface tension,electromagnetic force,and friction,as shown in Fig.4[5].In the welding pro-cess with high-current specifications,the electro-magnetic force has a considerable influence on the droplet shedding and transfer.

When using binary gas welding,the arc shape is wide and short and is located below the molten liquid at the end of the welding wire.At this time,the electromagnetic force acts upward to hinder the transition of the molten droplet to the molten pool.In high-current welding,the larger electromagnetic force suspends the molten droplet and even projects it out of the arc range to cause splashing,presenting a form of repelled transfer.The droplet grows con-tinuously under the action of surface tension when using ternary gas welding; part of the electro-magnetic force causes the droplet to shrink and pushes the droplet downward toward the molten pool,so the above-mentioned form of globular transfer is shaped.When using quaternary gas welding,the wire metal melts to form small droplets or continuous liquid columns.Under the action of the electromagnetic force,the liquid flows from the necked to expanded portion of the welding arc,promoting the droplet’s transition to the molten pool as a form of spray transfer.

Fig.4 Schematic diagram of the force on the droplet

Based on analysis on the role of different protective gas components:CO2has a large thermal conductivity,and CO and free oxygen are generated after the decomposition of CO2,which cools the arc and compresses the arc column.When using 80%Ar+20%CO2shielding gas,the arc is concentrated in a narrow area at the bottom of the droplet,which hinders its transition.The existence of O2is benefi-cial to overcome the cathodic floating phenomenon of the arc and increase its stability.At the same time,the surface tension of the molten metal can be reduced,and the droplet size can be decreased.When using 85%Ar+10%CO2+5%O2shielding gas,the arc can wrap the end of the welding wire without excessive compression.He has high ioniza-tion energy,increasing the arc energy,changing the arc shape,and raising the arc stiffness.The arc is short,and the shape is most conducive to the transition of the molten liquid to the molten pool when using 65%Ar+26.5%He+8%CO2+0.5%O2shielding gas.

4 Conclusions

The arc shape and droplet transfer behavior of the welding process are analyzed by high-speed photography,and the influence of different shielding gas components on welding stability is compared.

(1) In the high-current specification,the use of binary,ternary,and quaternary shielding gases pre-sents different droplet transfer modes of repelled,globular,and spray transfer,respectively.

(2) Depending on the shape of the arc,the electromagnetic force is hindered or promotes the droplet’s transition.

(3) Based on the three welding shielding gases used in this article,quaternary shielding gas can im-prove the stability of the welding process compared to the ternary and binary shielding gases.

Baosteel Technical Research2021年4期

Baosteel Technical Research2021年4期

- Baosteel Technical Research的其它文章

- Microstructure and properties of laser-arc hybrid welding of high-strength low-alloy steel

- Hot cracking susceptibility research in BTW1 austenitic high-manganese wear-resistant steel

- Research status of corrosion environment failure and safety assessment of pipeline welded joint

- Analysis of inclusions and precipitates in tough weld metal of X80 steel

- Influence of different microstructural features on impact toughness and crack initiation behavior of coarse grain heat-affected zone in X80 pipeline steel

- Preface