Penetration and internal blast behavior of reactive liner enhanced shaped charge against concrete space

Hao Zhang,Yuan-feng Zheng,Qing-bo Yu,Chao Ge,Cheng-hai Su,Hai-fu Wang

State Key Laboratory of Explosion Science and Technology,Beijing Institute of Technology,Beijing,100081,PR China

Keywords:Shaped charge Penetration Blast Concrete Numerical simulation

ABSTRACT Penetration and internal blast behavior of reactive liner enhanced shaped charge against concrete space were investigated through experiments and simulations.The volume of the enclosed concrete space is about 15 m3.The reactive liner enhanced shaped charge utilizes reactive copper double-layered liner,which is composed of an inner copper liner and an outer reactive liner,while the reactive material liner is fabricated by PTFE/Al(Polytetrafluoroethylene/Aluminum)powders through cold-pressing and sintering.Static explosion experiments show that,compared with the shaped charge which utilizes copper liner,the penetration cavity diameter and spalling area of concrete by the novel shaped charge were enlarged to 2 times and 4 times,respectively.Meanwhile,the following reactive material had blast effect and produced significant overpressure inside the concrete closed space.Theoretical analysis indicates concrete strength and detonation pressure of reactive material both affect the penetration cavity diameter.To the blast behavior of reactive material inside the concrete space,developing TNT equivalence model and simulated on AUTODYN-3D for analysis.Simulation results reproduced propagation process of the shock wave in concrete space,and revealed multi-peaks phenomenon of overpressure-time curves.Furthermore,the empirical relationship between the peak overpressure and relative distance for the shock wave of reactive material was proposed.

1.Introduction

Good performance of anti-penetration and modest cost make concrete widely used in ground defense fortifications.Compared with the projectile penetrating into the concrete,the tip velocity of metal jet under explosive driven is much higher,and the maximum velocity can be up to 6-8 km/s,which provides a deep penetration depth of 7-8 times charge diameter,while it is unable to produce satisfied after-effect damage behind targets.Presently,due to high energy content and unique impact-induced initiation characteristic of reactive materials [1-3],the reactive material liner which fabricated by cold-pressing and sintering processes has been used in shaped charges.The formed reactive jet creates large crater diameters against thick metallic and concrete targets [4-7],but its penetration depth is much lower than that of the metal jet.

Double-layered liner combines the advantages of inner and outer liner materials.Such as,the copper aluminum double-layered liner formed a jacketed jet which enlarges cavity diameter of concrete target,but without after-effect damage[8].Nevertheless,the reactive metal double-layered liner incorporates the advantages of both metal and reactive material.On the one hand,high-density metal ensures a deep penetration depth.On the other hand,reactive material blasts under explosive loading,which enhances the after-effect damage power.

To investigate the blast behavior of reactive material,Ames developed a vented chamber calorimetry technique to characterize the energy release of reactive material by evaluating overpressure in the test chamber[9,10],and the method has been widely used to evaluate different types of fragments [11-14].Meanwhile,the theoretical model has been proposed and modified to estimate its energy release [15,16].In addition,the reaction zone distribution and detonation-like characteristic of reactive material were also studied[17,18].However,for the blast characteristic of reactive liner shaped charge,experiment was only conducted in small volume test chamber [19],and lacks researches on the damage power to large physical targets,such as huge volume concrete space.

Based on the above considerations,static explosion experiments of the reactive liner enhanced shaped charge and metal liner shaped charge against concrete space were conducted firstly for comparison.Different hitting positions were considered.Then,a description for the penetration and internal blast behavior of reactive liner enhanced shaped charge against concrete space was presented.Subsequently,the expansion effect on penetration cavity by the novel shaped charge was theoretically analyzed.Lastly,TNT equivalence model was developed,and simulated on AUTODYN-3D to investigate the blast behavior inside concrete space.Simulation results reproduced propagation process of the blast wave in concrete space,and revealed the multi-peaks phenomenon of the overpressure.Furthermore,an empirical relationship between peak overpressure and relative distance for the shock wave of reactive material was obtained.

2.Experiments

2.1.The structure of reactive liner enhanced shaped charge

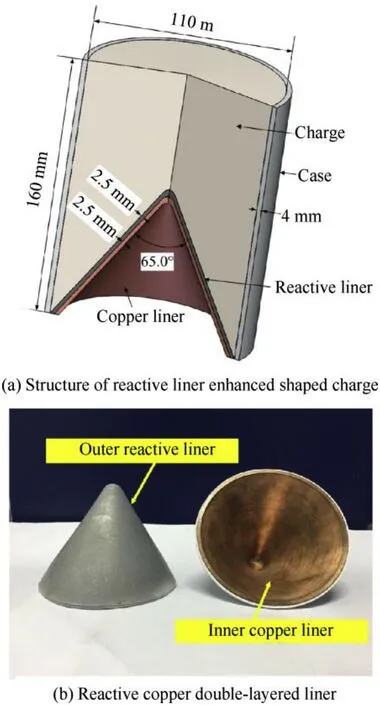

The reactive liner enhanced shaped charge is composed of explosive charge,aluminum case and double-layered liner as shown in Fig.1(a).The charge diameter and length are 110 mm and 160 mm,respectively.Thickness of the aluminum case is 4 mm.The double-layered liner consists of an inner copper liner and an outer enhanced reactive material liner,while the diameters of copper liner and enhanced reactive liner are 105 mm and 110 mm,respectively.The thickness and cone angle of the liners are both 2.5 mm and 65.

Preparation process of the reactive copper double-layered liner includes four steps.Firstly,PTFE/Al (Polytetrafluoroethylene/Aluminum)reactive powders were mixed uniformly with the mass ratio of 73.5%/26.5%.The average sizes of PTFE and Al powders were 100 μm and 140 μm respectively.Secondly,putting the mixed reactive powder into the mould for cold pressing at the pressure of 80 MPa,and the dwell time was approximately 3 min to form compact reactive liners.Thirdly,sintering the reactive liners in a vacuum oven,and the highest sintering temperature was up to 380C [20].Finally,assembling copper liner into the formed reactive liner for cold-pressing again to make them tightly attached to each other.The reactive copper double-layered liners used for static explosion experiments are presented as shown in Fig.1(b).In addition,copper liner shaped charge was prepared for comparison.The thickness and cone angle of the copper liner are 2.5 mm and 65,respectively.

2.2.Experimental setup

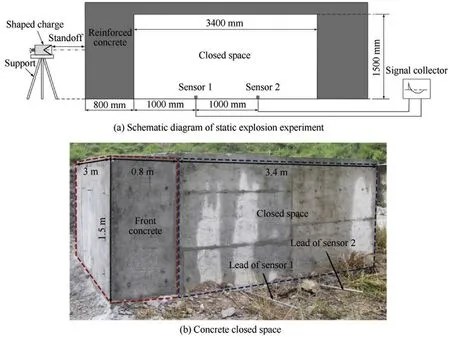

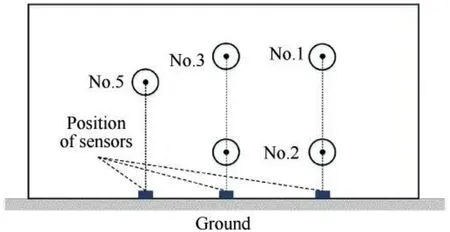

The schematic diagram of experimental setup for static explosion of the shaped charges against concrete space is shown in Fig.2(a).Shaped charge was placed on a height-adjustable support.The standoff distance between the shaped charge and concrete space was 1.5 times charge diameter (CD).The reinforced concrete thickness was 800 mm,with a compressive strength of 35 MPa.The concrete space was 3.4 m long,3 m wide and 1.5 m high.The volume of the space is about 15 m.Two pressure sensors were located on the ground surface of the concrete closed space to measure the ground reflected overpressure of shock wave inside the space.Specifically,the distances from sensor 1 and sensor 2 to the concrete back surface were 1 m and 2 m respectively.The leads which connected sensors with signal collector were protected by steel tubes as shown in Fig.2(b).Shaped charges were aimed at different positions of concrete by adjusting the height and position of the support.The hitting locations of the five static explosion tests to concrete are shown in Fig.3.Meanwhile,the positions of sensors were adjusted to ensure the sensors and shaped charge were on the same vertical plane in each test.

Fig.1.Schematic and real diagrams of reactive liner enhanced shaped charge.

2.3.Experimental results

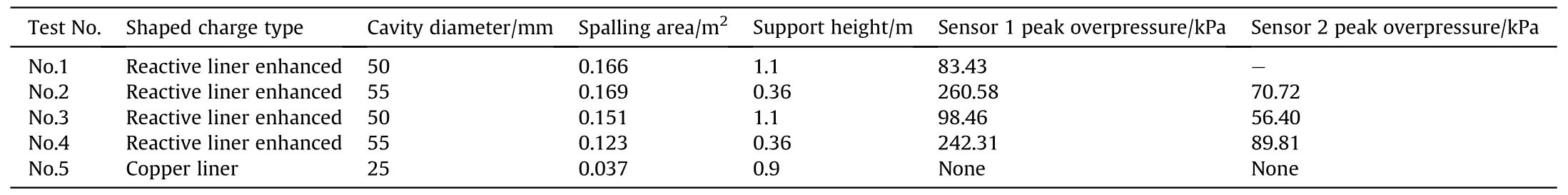

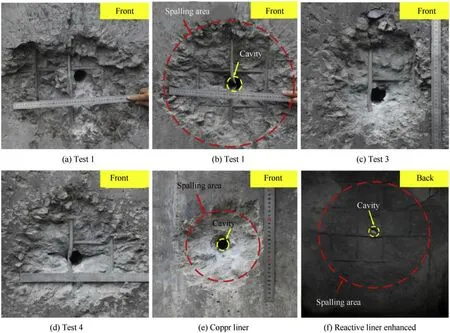

As the experimental data listed in Table 1,the penetration cavity diameter and spalling area of concrete front surface by the reactive liner enhanced shaped charges were both larger than those by copper liner shaped charge.Fig.4 presents penetration cavities and spalling areas of concrete by reactive liner enhanced shaped charges and copper liner shaped charge.The shaped charges all penetrated through the front concrete.Meanwhile the reactive liner enhanced shaped charge formed a remarkably larger spalling area on concrete front surface compared with that of copper liner shaped charge,as shown in Fig.4 (a)-(e).This is because the reactive material would react under explosive loading,and the strength of reactive material is lower than that of copper.Thus,under explosive driven,part of the reactive material extended over the concrete front surface without penetration,and induced a violent reaction upon colliding with the concrete target,which formed larger spalling area on concrete surface.Fig.4 (f) depicts typical back surface of the concrete after impacting by reactive liner enhanced shaped charge.When the shaped charge against the concrete target,a shock wave propagated into the concrete,besides,the tensile strength of concrete is much lower than its compressive strength.Therefore,when the concrete subjected by the reflected rarefaction wave from the back surface,tensile fracture produces a larger spalling area on back surface of concrete.

Fig.2.Experiment setup and concrete closed space.

Fig.3.Hitting locations of shaped charges in each test.

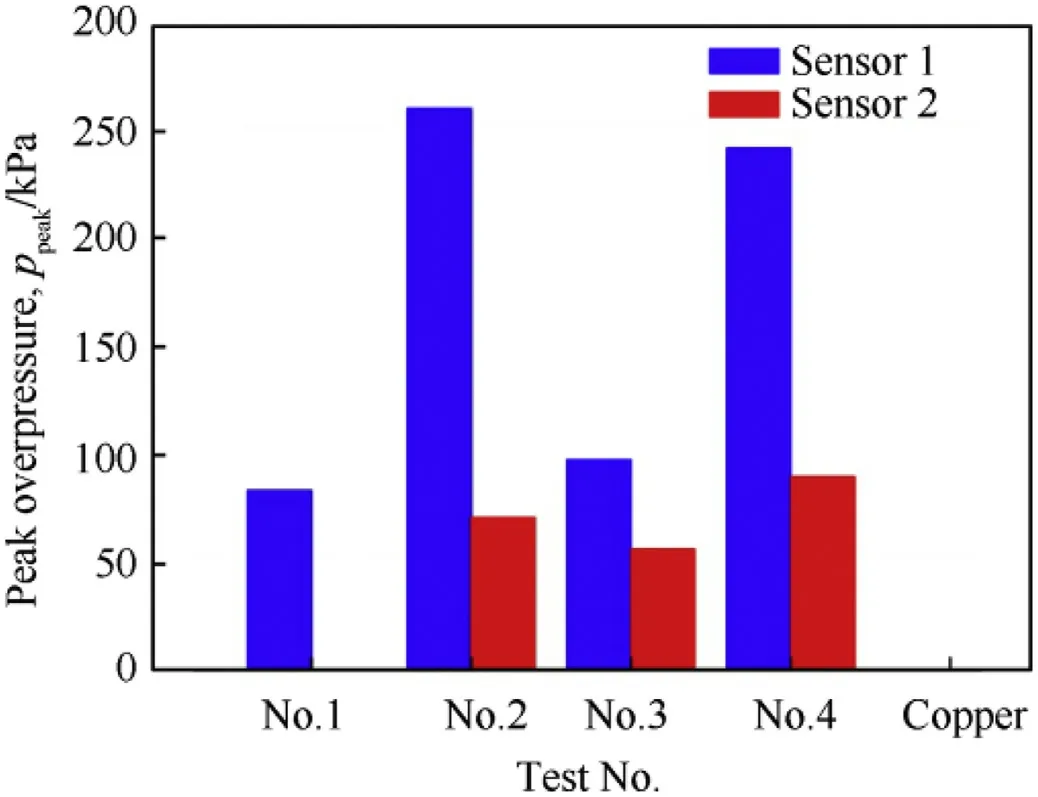

After penetrating through the concrete,the residual reactive material reacted and had a detonation-like phenomenon in the concrete space.It generated a shock wave which propagated in the closed space.The peak overpressures which were measured by the sensors were listed in Table 1,in which the reactive liner enhanced shaped charges produced significant behind-target overpressures,while there was no obvious overpressure produced by copper liner shaped charge.Moreover,with the support heights decreasing,the distances between the explosion center of reactive material and ground sensors reduce,and therefore the measured peak overpressures increase.In addition,sensor 2 lead was broken in test 1,and no signal was obtained.

Fig.5 depicts the sensor 1 and sensor 2 peak overpressures of each test.The support heights of the shaped charges in test 2 and 4 were lower than those in test 1 and 3,which results in closer distances between the ground sensors and explosion center of the reactive material.Thus,test 2 and 4 depict the peak overpressures of the blast wave near zone,while test 1 and 3 record peak overpressures in far zone.Observing from the peak overpressure values of sensor 1 and sensor 2 in each test,it shows that the peak overpressures of sensor 1 were all higher than those of sensor 2,and more importantly,the differences of peak overpressures between sensor 1 and 2 in test 2 and 4 were larger than that in test 3,which illustrates peak attenuation speed of the shock wave decreases faster in near zone than in far zone.

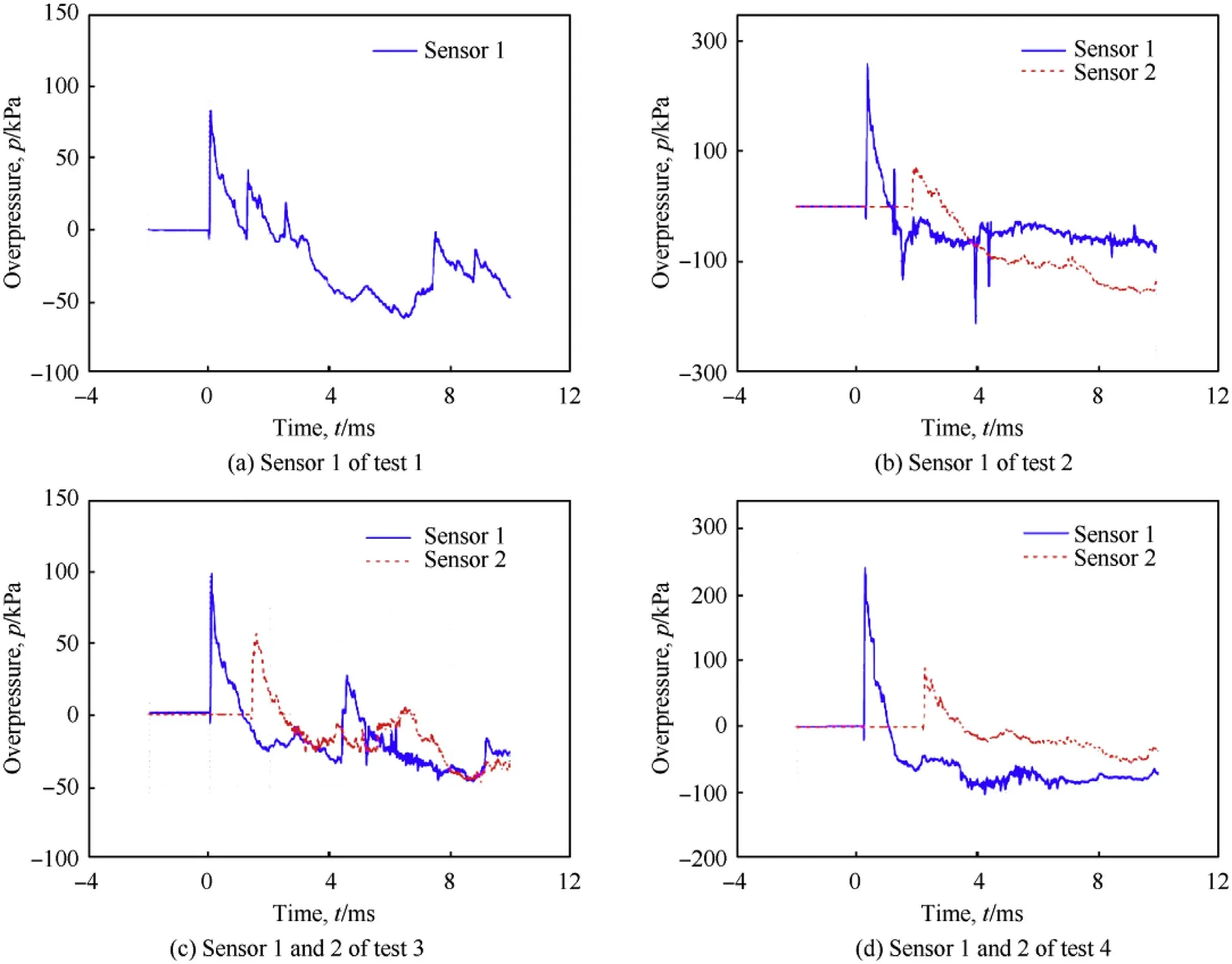

Fig.6 shows ground reflected overpressure-time curves of each test which were measured in the concrete closed space.The positive phase durations in Fig.6 (a) and (c) are longer than those in Fig.6(b)and(d)respectively.This was because in test 1 and test 3,the distances from the explosion center to the sensors were farther than those in test 2 and test 4,and the positive phase duration of the shock wave increased with the propagation distance.In addition,the overpressure-time curves of Fig.6(a)and(c)exhibit multipeaks phenomenon,and the reason is further explained in the discussion.

3.Discussion

3.1.Phenomenological description of penetration and internal blast process

Compared with the metal liner shaped charge,the reactive liner enhanced shaped charge combines the benefits of metal liner and reactive material liner.On the one hand,the inner metal liner shapes a precursory high density metallic jet which can produce large penetration depth and an initial penetration channel.On the other hand,the outer reactive material liner forms reactive penetrator which releases chemical energy and produces after-effect overpressure in the concrete space after penetrating through the front concrete.

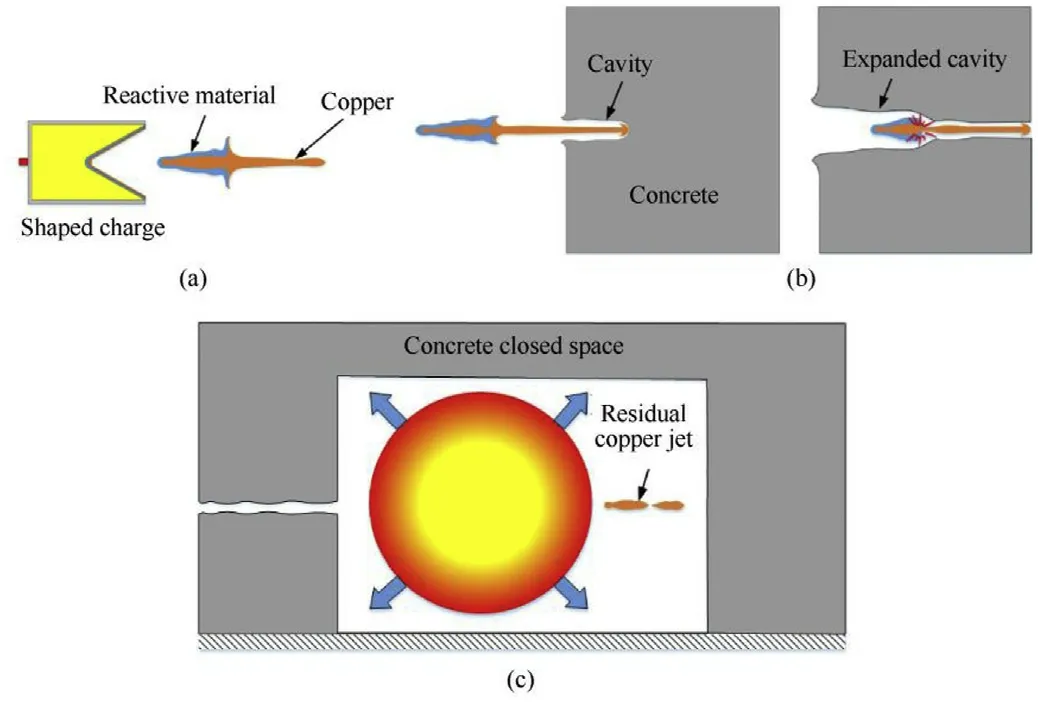

The penetration and internal blast process of reactive liner enhanced shaped charge against concrete space can be divided into three stages as Fig.7(a)-(c)depict.Fig.7(a)presents the formation of copper-reactive jet under explosive driven,it shows that the jet head is made by copper while the reactive material mainly wrapped on the surface of the slug.Fig.7 (b) shows the penetration process of the jet,the copper jet penetrates the target firstly,and then due to the detonation-like characteristic of the reactive material,the reactive penetrator enlarges the cavity diameter as it penetrates through the channel.Fig.7 (c) presents the residual reactive material blasts in the concrete closed space after penetrating through the concrete target,and the shock wave propagatesin the closed space.The residual copper jet continues to fly forward to the rear concrete closed space.

Table 1 Cavity diameters and behind-target peak overpressures.

Fig.4.Concrete surfaces hit by different types of shaped charges.

Fig.5.Peak overpressure at sensor 1 and sensor 2 of the tests.

3.2.Expansion effect on penetration cavity

The cavity diameter of concrete formed by the reactive liner enhanced shaped charge is larger than that subjected by copper liner shaped charge.This is due to the detonation-like characteristic of reactive material,which results in a violent blast in the penetration cavity,and expands the pre-penetrated cavity diameter formed by the front copper jet.Fig.8(a)illustrates the schematic of expansion effect on concrete penetration cavity by the reactive liner enhanced shaped charge.Here,P is the average detonation pressure in the penetration cavity,d is the diameter of the prepenetrated cavity by precursory copper jet,dis the ultimate expanded cavity diameter by the blast of reactive material,and σis the concrete strength under explosive loading.The stress distribution of penetration cavity depicts in Fig.8 (b).As it shows,the stress of pre-penetrated cavity wall equals to the detonation pressure of reactive material,while the stress of ultimate cavity wall declines to zero.Assuming the stress decreases linearly along the radial direction of penetration hole.

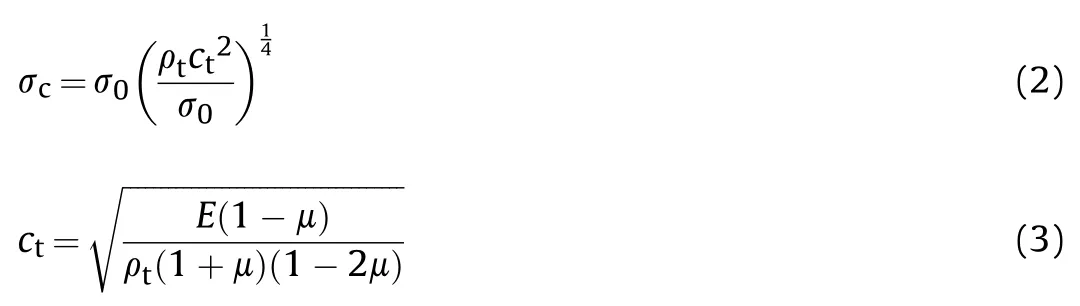

Then,the expansion ratio of cavity diameter produced by the reactive liner enhanced shaped charge can be predicted from Eqs.(1)-(4).Firstly,the average detonation pressure in the penetration cavity P can be obtained from Eq.(1),where P,ρ,D are the detonation pressure,density and detonation velocity of reactive material respectively.For the reactive material in the experiments,the material density and detonation velocity are 2.27 g/cmand 3273.3 m/s,respectively[21,22,26].

Fig.6.Overpressure-time curves in the concrete space.

Fig.7.Schematic of the penetration and internal blast processes of reactive liner enhanced shaped charge against concrete space.(a) Jet formation.(b) Penetration process.(c) Blast of reactive material in concrete space.

Then,the dynamic concrete strength σunder explosive loading can be calculated from Eqs.(2) and (3) [23],where ρ,care the density and sound speed of the concrete,the values of them are 2.3 g/cmand 3900 m/s,respectively.σ,E,μ are the uniaxial compression strength,Young's modulus and poisson ratio of the concrete respectively,for C35 concrete the values are 35 MPa,31.5 GPa and 0.2,respectively[24].

Finally,expansion effect on penetration cavity by the reactive liner enhanced shaped charge can be described from Eq.(4) [25],where d is the pre-penetrated cavity by precursory copper jet,and dis the ultimate penetration cavity diameter.As Eq.(4)described,when the average detonation pressure in penetration hole is lower than the dynamic concrete strength,the cavity diameter maintains the same as that produced by precursor copper jet,and the cavity expansion ratio is equal to 1.However,when the detonation pressure in the penetration cavity is higher than the dynamic concrete strength,then the ultimate cavity diameter is expanded.

Fig.8.Penetration cavity expansion under blast of reactive material.

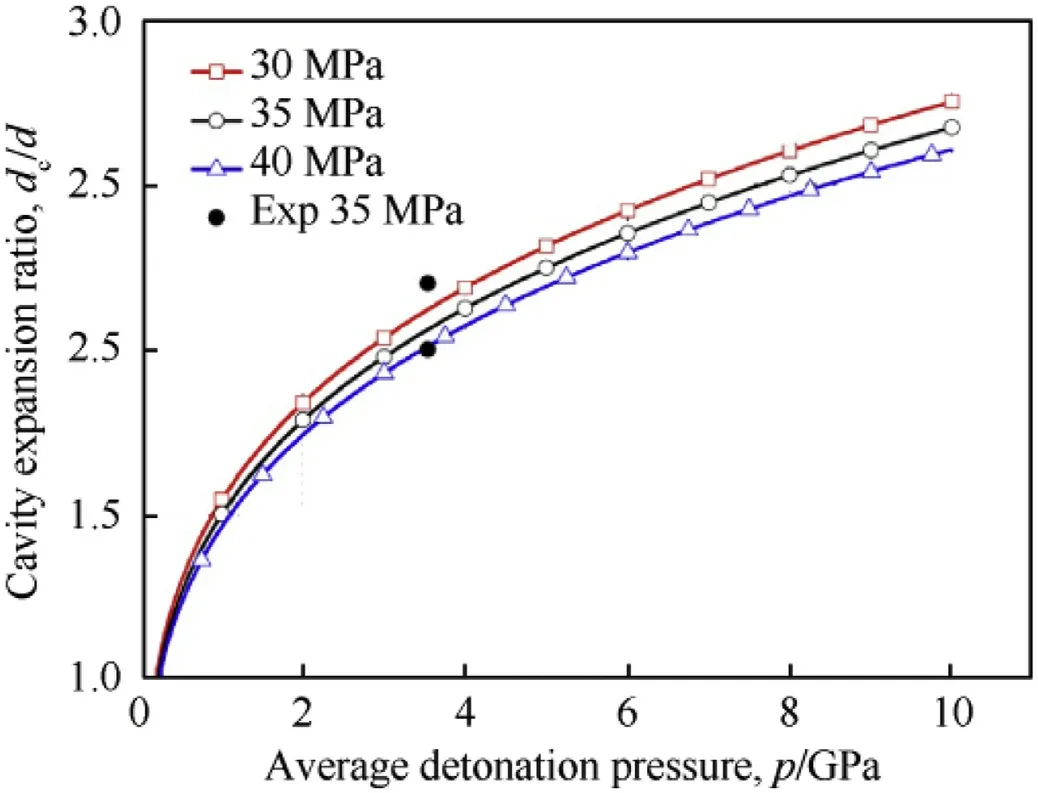

Fig.9 shows the relationship between cavity expansion ratio of concrete with three different compression strengths and average detonation pressure in penetration channel.The cavity expansion ratio increases with decreasing concrete strength.For the concrete with 35 Mpa compression strength,as the black dots marked in the figure,the experimental expansion ratios for the reactive liner enhanced shaped charge are about 2.0,which are in agreement with theoretical prediction.Moreover,the cavity expansion ratio increases with the growing detonation pressure,which indicates the detonation pressure of reactive material is an important factor to affect the expansion on penetration cavity.

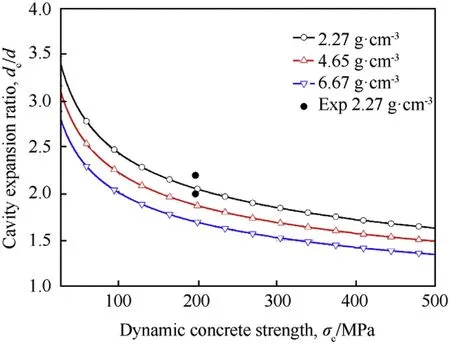

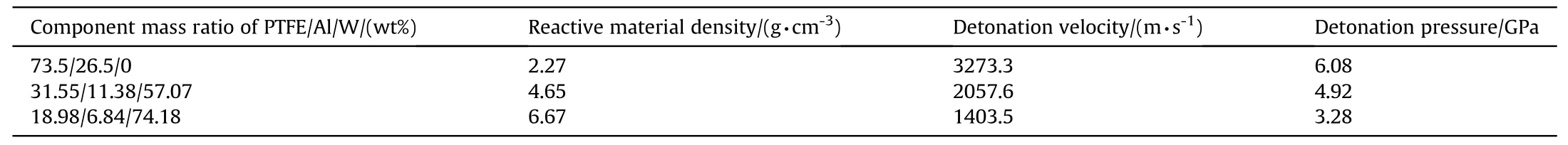

Fig.10 reveals that the cavity expansion ratio versus the concrete strength while using different densities of reactive material.For the polymer-based reactive material,tungsten is necessarily introduced to enhance the material density.Three different densities of PTFE/Al/W reactive composites are presented,and the component mass ratio and detonation velocity of them are listed in Table 2[21,22,26].As Fig.10 depicts,the penetration cavity expansion ratio decreases with the increase of concrete strength.Moreover,the detonation velocity of the low-density reactive material without tungsten is the highest,and it produces the highest detonation pressure and the largest cavity expansion ratio.

Fig.9.Penetration cavity expansion ratio versus average detonation pressure.

Fig.10.Penetration cavity expansion ratio versus dynamic concrete strength.

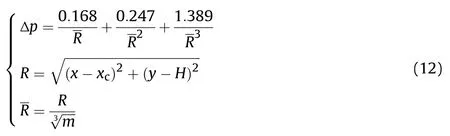

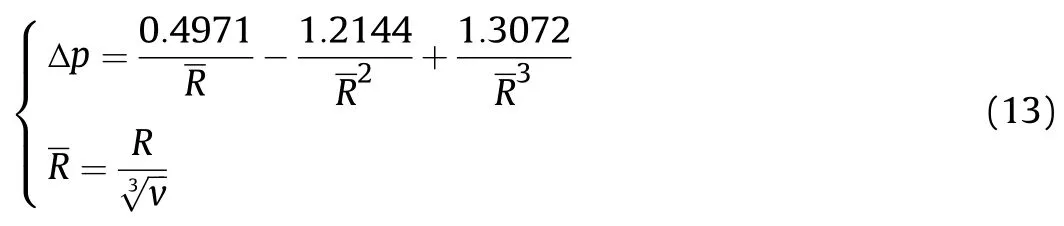

3.3.Blast behavior inside concrete space

After penetrating through the front concrete,the residual reactive material blasts and has a detonation-like phenomenon in the closed space.It generates a blast wave which propagates in the closed space.To investigate this phenomenon,it is assumed that there is an explosion center of reactive material in the concrete space.Because the suitable equation of state describing reactive material has not been well developed [26],moreover,the experimental result reveals that the overpressure curve shape of reactive material and the high explosive are similar due to the detonationlike characteristic of reactive material.Thus,developing a TNT equivalence model substitutes for the blast wave of the reactive material,and simulates on AUTODYN-3D to investigate the blast behavior of reactive material in the concrete space.

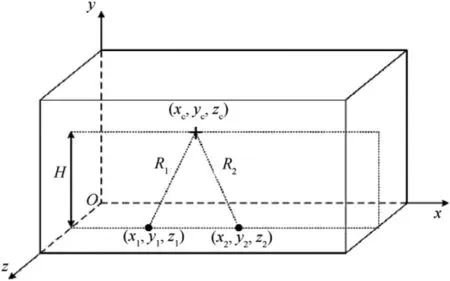

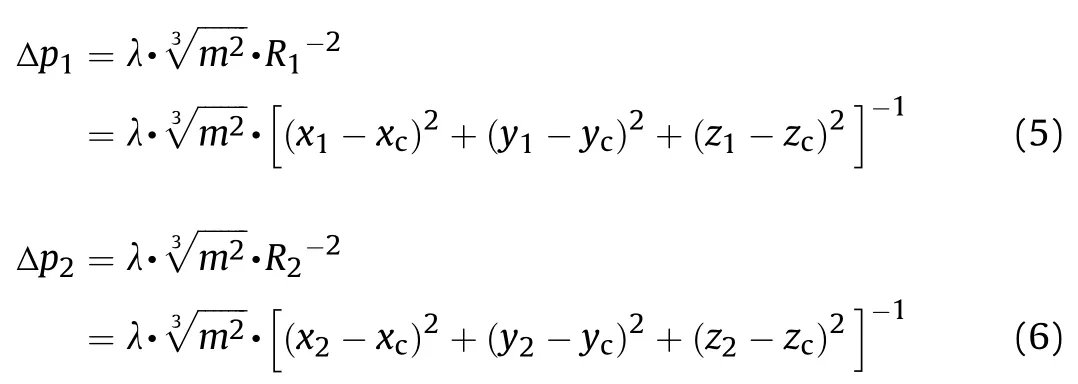

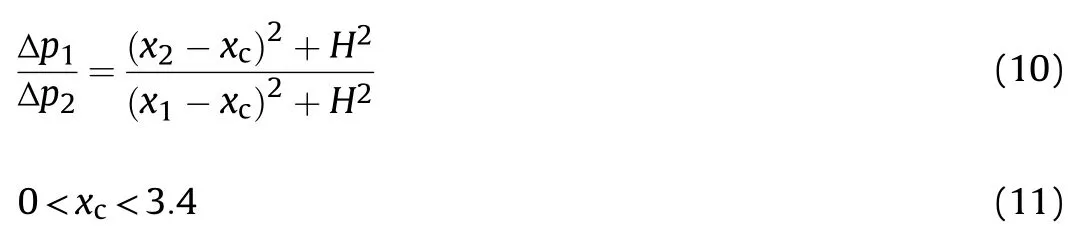

The TNT equivalence model was developed based on thepropagation characteristic of shock wave and the geometric relationship between the position of sensors and the explosion center of reactive material.Fig.11 depicts the geometric relationship,as it shows,(x,y,z),(x,y,z),(x,y,z) are the coordinates of the explosion center,sensor 1 and sensor 2 respectively.H is the height from the hitting position of shaped charge to the ground.Rand Rare the distances from the explosion center to sensor 1 and sensor 2 respectively.Eqs.(5) and (6) describe the peak overpressures at sensor 1 and 2,where λ is a constant and m is the equivalent TNT mass [27].

Table 2 Parameters of reactive materials with three densities.

Fig.11.Geometric relationship between explosion center and pressure sensors.

Eq.(7) describes the ordinates of sensors 1 and 2.Because the sensors are placed on the ground surface,thus the ordinates of them equal to 0.The jet penetrates normally into concrete space,and therefore the explosion height of residual reactive penetrator is the same as the support height of shaped charge as shown in Eq.(8).Because the shaped charge,sensor 1 and sensor 2 are all in the same vertical plane,then Eq.(9) can be obtained.

Taking Eqs.(7)-(9) into Eq.s (5)-(6),and dividing Eq.(5)with Eq.(6),then Eq.(10) was obtained.By solving Eq.(10),the coordinate of the explosion center can be obtained.Since the explosion point (x,y,z) locates inside the concrete space.Thus,the horizontal ordinate of explosion point xshould range from 0 to 3.4 as shown in Eq.(11).

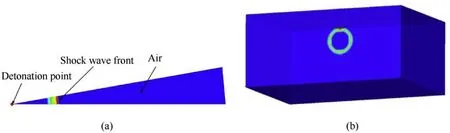

Subsequently,numerical simulations of the above three tests are performed using AUTODYN Euler solver.The three-dimensional model is as the same size as the real concrete closed space.The enclosed space is 3.4 m long,3 m wide and 1.5 m high.Considering the calculation efficiency,the propagation of the initial blast wave is calculated in one-dimensional model firstly,and the element size is 1 mm.Then,the one-dimensional calculation results are mapped to three-dimensional model when the initial blast wave propagates to the nearest wall of the three-dimensional model.Fig.12 (a)-(b)show the one-dimensional and three-dimensional models respectively.The equation of state and material parameters for AIR and TNT are listed in Table 4.Rigid boundary condition is used to simulate the reflection of shock wave on the wall.

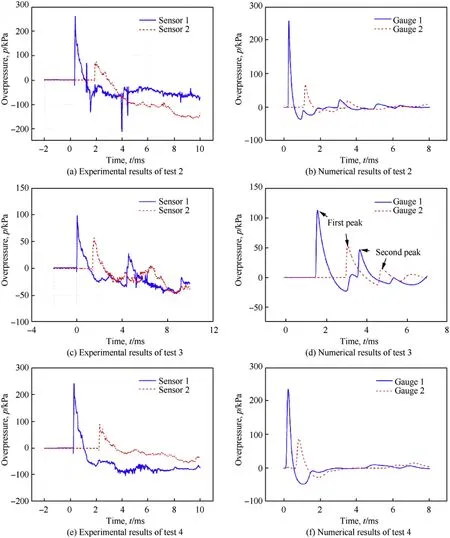

Fig.13 depicts the experimental and numerical results of the ground reflected overpressure curves of sensor 1 and 2 in each test.As it depicted,the numerical and experimental wave shape are similar,which indicates that the reactive material has detonationlike characteristic,and blasts as explosive.The peak overpressures of the experiments and simulations are almost the same,while comparing the interval time between the initial peak overpressure of the two sensors,the experimental interval time are longer than that of the simulation results.That indicates the propagation speed and peak attenuation speed of the shock wave for the reactive material are both slower than those of the highexplosive.Meanwhile,as depicted in Fig.13(c)-(d),the simulation curves exhibit multi-peaks phenomenon,and are consistent with the experimental results.It is because the hitting locations of the shaped charges against the concrete were different,which results in different explosion positions of reactive material inside the concrete closed space.When the explosion center is near the concrete wall,the pressure sensors record the reflection waves from the concrete side walls,and the overpressure-time (p-t)curves appear multi-peaks after initial peak.

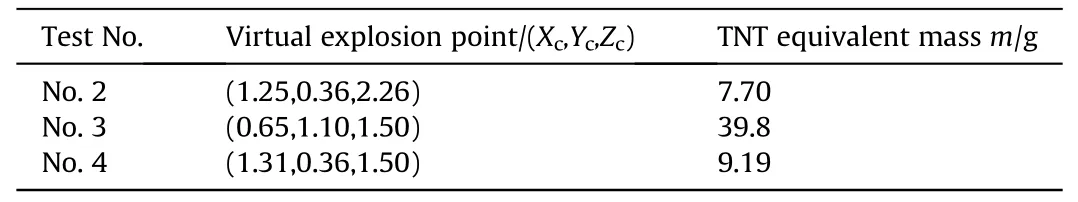

Table 3 Coordinates of virtual explosion points and equivalent TNT mass.

Fig.12.Calculation models.(a) one-dimensional model,(b) three-dimensional model.

Table 4 Equation of state for AIR and TNT [29].

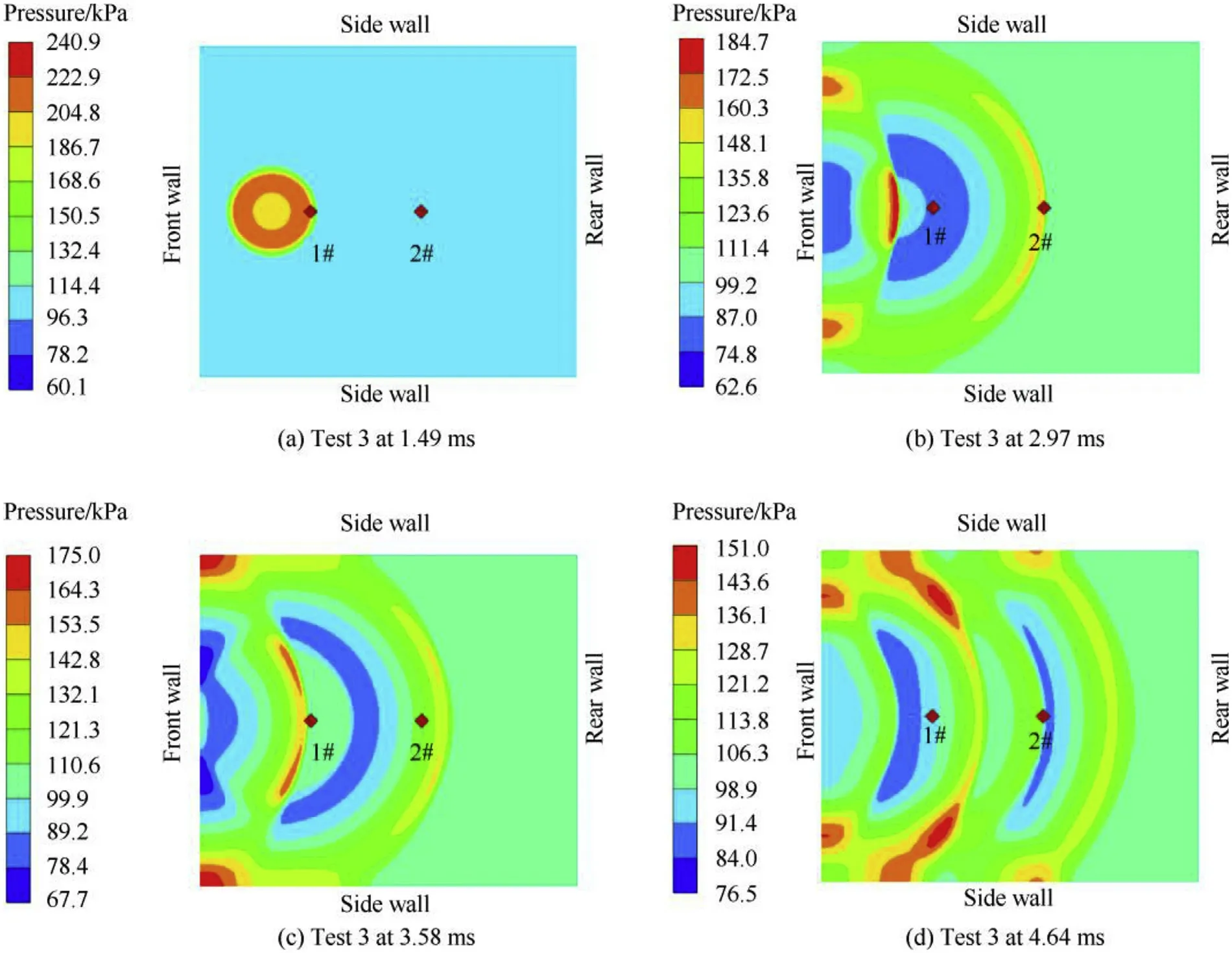

Taking test 3 as an example,Fig.14(a)-(d) show the ground pressure contours of the shock wave propagation in the closed space.As Fig.14(a) reveals,the initial shock wave propagates to sensor 1 which was marked by the red dot,while sensor 2 is still in ambient pressure at this moment.This corresponds to the first peak of the overpressure-time (p-t) curve for sensor 1 in Fig.13(d).Subsequently,the initial shock wave propagates to sensor 2,which corresponds to the ground pressure contour shown in Fig.14(b),and the shock wave has already reflected from the front wall.At this moment,the overpressure-time(p-t)curve of sensor 2 appears the first peak overpressure as Fig.13(d) depicts.Fig.14(c) shows the reflection wave from front wall has arrived at sensor 1,and the sensor records the second peak overpressure of the shock wave.As the shock wave continues propagating,the wave-front of the reflection wave arrives at sensor 2 as depicted in Fig.14(d).Then the overpressure-time curve of sensor 2 records its second peak.In addition,because the explosion center of the shock wave in test 3 locates on the central plane of closed space.Thus,the ground pressure distribution of the shock wave is symmetrical in the space.

4.Conclusions

Static explosion experiments,simulation and theoretical analysis were conducted to investigate the penetration and internal blast behavior of reactive liner enhanced shaped charge against concrete space.The reactive copper double-layered liner is composed of an inner copper liner and an outer enhanced reactive liner,which combines the advantages of the two materials.The main conclusions are as follows:

(1) Compared with the copper liner shaped charge,the reactive liner enhanced shaped charge shows greater damage effect to the concrete space.Experiments indicate that the novel shaped charge produces larger penetration cavity diameter and spalling area to the concrete.More importantly,the residual reactive material blasts and produces significant overpressure in the concrete space after penetrating through the front concrete.

(2) The expansion effect of reactive liner enhanced shaped charge on penetration cavity of concrete with different compression strengths is theoretically predicted.Moreover,the density of reactive material also affects the expansion ratio due to the difference of detonation pressure,and the penetration cavity diameter decreases with the increase of the concrete strength and the density of reactive material.

Fig.13.Experimental and numerical results of overpressure-time curves.

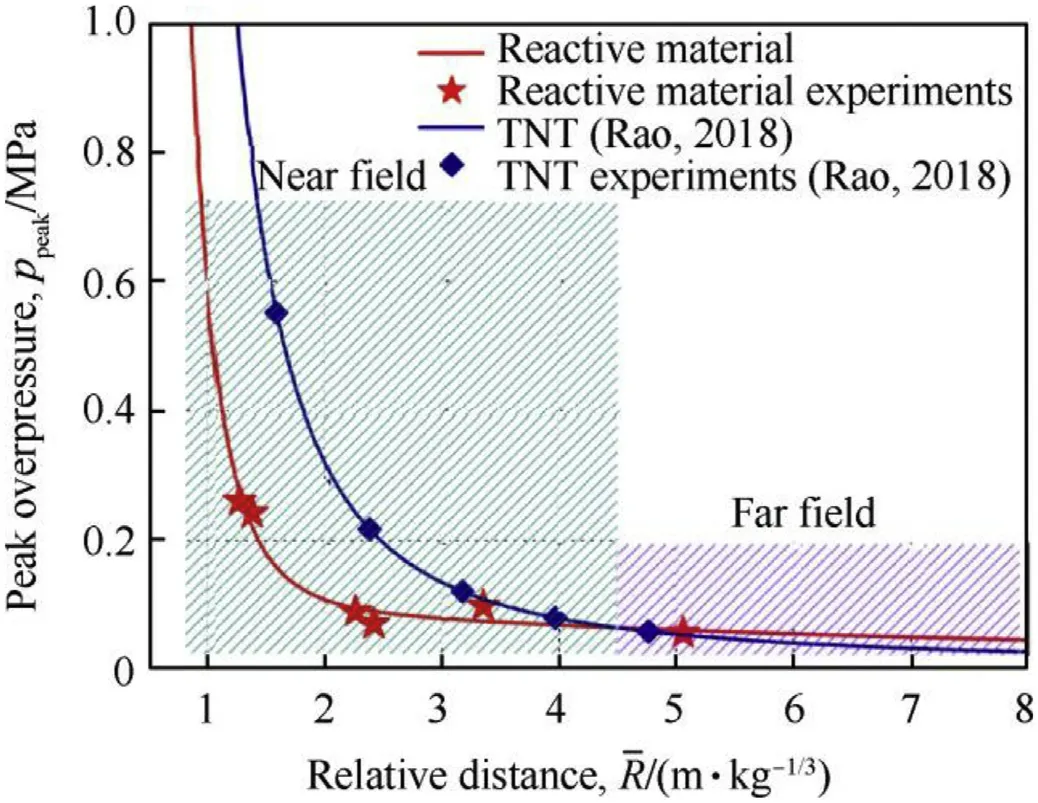

(3) Developing TNT equivalence model and simulate on AUTODYN-3D to investigate the internal blast behavior of reactive material.The explosion center and equivalent TNT mass are well determined.The simulation reproduces propagation process of the shock wave inside concrete space,and revealed the multi-peaks phenomenon of the overpressure.Moreover,the relationship between peak overpressure and relative distance of the shock wave for reactive material was proposed.It shows that the peak overpressure of shock wave for the reactive material performs much lower in near zone,but was slightly higher in far zone compared with that of TNT.

Fig.14.Ground pressure contours of Test 3.

Fig.15.Peak overpressures versus relative distance for the reactive material and TNT.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Funding:This work was supported by National Natural Science Foundation of china [grant number:U1730112].

- Defence Technology的其它文章

- Ultra-lightweight CNN design based on neural architecture search and knowledge distillation:A novel method to build the automatic recognition model of space target ISAR images

- Dense copper azide synthesized by in-situ reaction of assembled nanoporous copper microspheres and its initiation performance

- Ballistic impact response of resistance-spot-welded (RSW) doublelayered plates for Q&P980 steel

- Calculating detonation performance of explosives by VLWR thermodynamics code introduced with universal VINET equation of state

- Design and motion analysis of reconfigurable wheel-legged mobile robot

- A Multi-UCAV cooperative occupation method based on weapon engagement zones for beyond-visual-range air combat