Effects of Biochar on Substrate Degradation and Ammonia Emission during Aerobic Composting of Chicken Manure

HE Yuan-ling, XING Ze-bing,2*, WU Xiao-dong

1. School of Engineering, Shanxi Agricultural University, Taigu 030801, PRC;

2. The Centre of Experimental Education, Shanxi Agricultural University, Taigu 030801, PRC

Abstract In this study, chicken manure and Caragana korshinskii Kom powder were used as the main raw materials with different amounts of biochar added to test four aerobic composting treatment groups A, B, C and D with laboratory composting fermenters and testing apparatus, and new insight into biochar’s nitrogen conservation mechanism was gotten, based on the experimental data and related exploration such as the physical and chemical properties of the final products,the changing interactions among nutrient elements and other elements, and the relationship between substrate degradation and the amount of biochar used as well as the best formula for reducing ammonia emission. The results showed that the proper proportion of the added biochar to the other elements was conducive to less ammonia emission and nitrogen loss during the aerobic composting. The composting effect of Treatment C (biochar at 20%) was the optimal in the test, where in the composting temperature rose the most rapid and the earliest to the maximum temperature 52.5℃,with the least nitrogen loss. An effective, safe and high-quality resource utilization of chicken manure was established through the aerobic composting with reasonable material mixture proportion.

Key words Biochar; Chicken manure; Aerobic composting; Ammonia emission

1. Introduction

In recent years, China’s livestock and poultry breeding industry has developed rapidly. According to the China Agricultural Yearbook statistics, more than 4 billion tons of livestock manure was discharged into the environment each year in China[1]. In 2015, it was as high as 4.5 billion tons, which formed one of the main agricultural pollution sources in China[2-3]. Livestock manure is rich in organic matter and mineral nutrient elements such as nitrogen, phosphorus and potassium and is an important fertilizer resource in agricultural production. Thermophilic aerobic composting has proven to be an effective way to transform livestock manure to high-quality organic fertilizer with reduction, eco-friendly results and resource utilization[4]. In the meantime, coincident with the transformation and degradation of organic matter during the aerobic composting, ammonia and other harmful gas emissions have been generated, entailing a large amount of nitrogen loss as well as serious pollution of the atmosphere and the environment.

Some studies have shown that exogenous additives such as biochar could effectively alleviate and reduce nitrogen loss and harmful gas emission during the aerobic composting[5]. Biochar is an important byproduct of high-temperature pyrolysis of biomass under anaerobic or anoxic conditions[6].Biochar has excellent properties such as high stability,developed pore structure and abundant functional groups, which is of some significance to both the investigation of aerobic composting processes and environmental pollution control.

This study was conducted to use some aerobic composting fermenters and corresponding detection apparatuses to practise the aerobic composting of chicken manure supplemented with biochar, perform dynamic characterization analysis of some important indicators such as temperature and ammonia gas in the process of composting, and investigate the effect of different proportions of added biochar on the aerobic composting of chicken manure, which provided theoretical and methodological support for optimizing the aerobic composting process, as well as new insight on the ammonia emission reduction mechanism.

2. Materials and Method

2.1. Experimental time and field

The aerobic composting test of chicken manure was started in February 2018 in the College of Engineering, Shanxi Agricultural University.

2.2. Experimental material

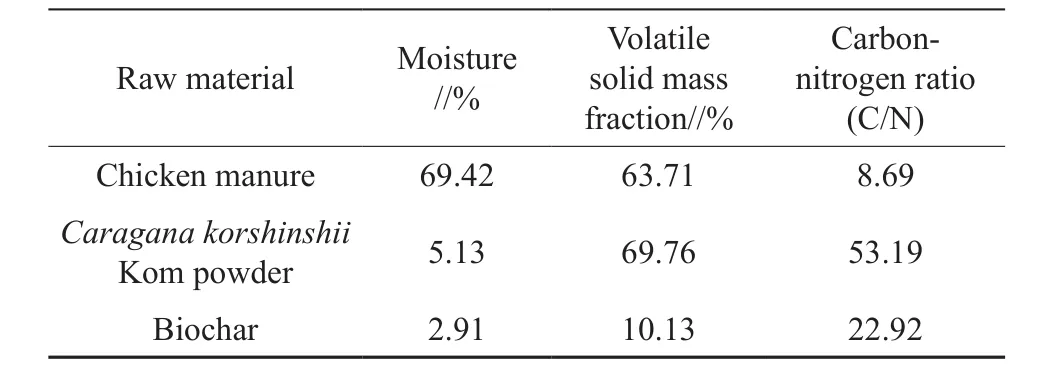

The principal raw material of this aerobic composting experiment was fresh chicken manure collected from the chicken farm of the Experimental Station of Shanxi Agricultural University. The plugging material, a shrub species known asCaragana korshinskiiKom, was selected from Wangjia Village,Dingxiang County in the northern Shanxi Province,where it had been grown for more than three years.Its branches were used by stoving, crushing, and screening with the help of a sieve with a hole diameter of 0.5 mm or 0.5 mm-diameter holes. The experimental biochar was a sort of self-madeCaragana korshinskiiKom biochar from the Material Mechanics Laboratory of Shanxi Agricultural University. Under the anaerobic condition, the biochar was made by the pyrolysis and carbonization ofCaragana korshinskiiKom at a high temperature of 600℃ in a muffle furnace with a particle size of 1 to 3 mm or 1 to 3 mm-sized particles. The basic physical and chemical properties of composted raw materials are shown in Table 1.

Table 1 The basic physical and chemical properties of the fermentation feedstock

The chicken manure had a low carbon-nitrogen ratio and a high moisture content, whileCaragana korshinskiiKom powder had a lower moisture content and a higher carbon-nitrogen ratio (Table 1). The combination of the two could well regulate the carbon-nitrogen ratio and moisture content of initial mixed materials to meet the growth needs of microorganisms in the aerobic composting process.Moreover, biochar with a particle size of 1 to 3 mm was conducive to maintaining a fluffy and long-time empty structure, thereby providing a suitable porous medium environment for benign aerobic composting.

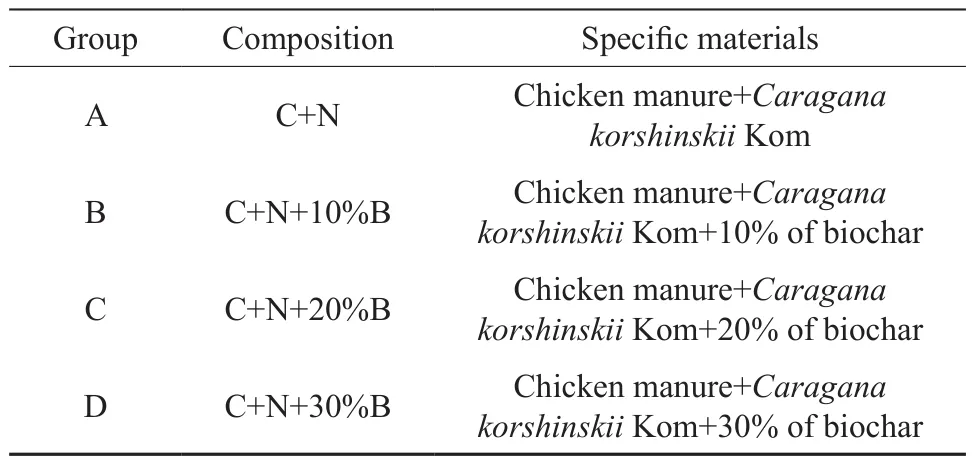

2.3. Experimental design

There were a total of four treatments with three replicates in this experiment (Table 2). In the experiment, the plastic composting bins were used as simulated composting devices, each of which was composed of two parts: the cover and the bin body.The size of the bin body was 25 cm×23 cm×23 cm.The bin cover was outfitted with a YW-068 inflate& deflate electric air pump (Qiangtai Machinery Manufacturing Ltd., Wuxi, China) to maintain the aerobic state of composting materials and pool the gas generated during the fermentation. The mass proportion of fresh chicken manure andCaragana korshinskiiKom powder was calculated according to a carbon-nitrogen ratio of 25:1. Then, the biochar with 10%, 20% and 30% mass fraction was added in the order given from Table 2 (B~D) based on a preset gradient. Finally, the chicken manure,Caragana korshinskiiKom powder and the predetermined biochar were mixed evenly and the initial moisture content was adjusted to 65%.

Table 2 Experimental treatments

2.4. Determination of indicators and methods

In the process of experimentation, about 50.0 grams of the upper, middle and lower layers of the composting heap were sampled separately on the 1st, 5th, 10th, 15th, 20th, 25th, 30th, 35thand 40thd after composting fermentation. Then, one extracted sample at a time was uniformly mixed and dried to a constant weight at a temperature of 105°C so that the moisture content of each sample was measured. It should be noted that, after each sampling, the sample was evenly and thoroughly turned once and piled up to form the original shape after being turned.

At 19:00 every day, a portable suction gas analyzer, a Bestone AR8500 ammonia gas detector(Bestone Industrial Ltd., Shenzhen, China), was used to monitor the ammonia emission during the composting fermentation. At the same time, specific emission of ammonia every single day was collected by dint of the YW-068 inflate & deflate electric air pump for subsequent calculation of the average ammonia release rate of the treatment and control groups.

The heap temperature was measured daily,using a reasonable process where the heap was first temperature-measured, followed by sampling and finally turning the heap.

Lastly, the application of a vario EL - elemental analyzer (LT Scientific, Inc., Carson City, NV, USA)determined the contents of carbon and nitrogen after chicken manure became thoroughly decomposed.Then, the corresponding carbon-nitrogen ratio could be determined.

2.5. Data processing

In terms of experimental data, its statistical analysis and drawing were completed by Excel 2010 and SAS Statistics 9.1.

3. Results and Analysis

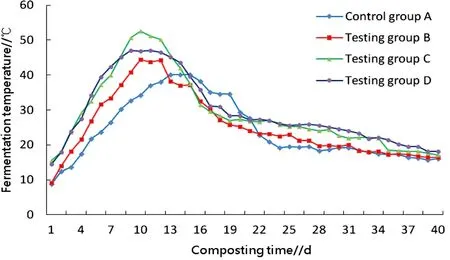

3.1. Effects of different amounts of biochar added on composting temperature

For the composting system, temperature is an important indicator of microbial life activity[7]. The change of temperature can well characterize the degradation process of organic matter, and it is a crucial condition for chicken manure composting if it is harmless and stable. The heap temperatures of the four treatment groups first showed an increase and then a decrease with the progress of composting fermentation (Fig. 1). In general, the three treatments with biochar added had a faster temperature rise and higher temperatures than the control group, which indicates that adding biochar could partly upgrade the fermentation temperature and shorten the cycle of composting maturity. However, the effect of an unequal additive amount of biochar on composting temperature presented an inconsistence. Among them,Treatment Group C had a rapid temperature rise and a maximum temperature of 52.5°C that lasted four d, and the highest temperature of Treatment Groups B and D was recorded at 44.5°C and 47.0°C,respectively. The treatment groups did not all reach the hygienic standard for the harmlessness of manure in China. So clearly, the biochar application amount plays a significant role in the fermentation temperature and composting maturity time of chicken manure.

Fig. 1 Dynamic changing curves of temperatures during composting

3.2. The effect of unequal amounts of biochar added on moisture content in a composting heap

The water in the composting materials can dissolve organic matter, provide nutrients for microorganisms, participate in the metabolism of microbes, and take away part of the heat during its evaporation. Accordingly, it is an important index to mirror the degree of composting maturity and is also one of the main factors affecting the composting effect. According to the standardization requirements of composting treatment, the moisture content of the initial mixed material is generally regulated between 50% and 80%. In this experiment, the initial moisture content was adjusted to 60% or so. However, due to high temperature and ventilation, some of the water was lost along with heat as gas emissions such greenhouse gases as carbon dioxide, methane and nitrogen oxides went on. Consequently, the moisture content of the heap displayed a decline during the composting fermentation.

In the four treatment groups tested, the moisture content of every heap manifested a gradual drop.As for Treatment Groups B, C and D, their moisture content slowly decreased from 62% to 57%, 58%to 39%, and 43% to 46% respectively, whereas its moisture content relatively and quickly went down from 65% to 35.5% in Control Group A (Fig. 2). This was chiefly due to the excessively high temperature in the preliminary stage of the composting process,which caused a large amount of moisture to evaporate;thus, the moisture content fell. Furthermore, the decline in moisture content at the preliminary stage of composting fermentation was more dramatic than at the middle and later stages.

Fig. 2 Dynamic changes of moisture in the compost of chicken manure

As a whole, the decrease in the moisture content of the control group is much more obvious than that of the other treatment groups. The dominating reason was that the pore structure of biochar allowed it to have a great specific surface area, which resulted in a strong absorption capacity in which its surface could take in certain moisture[8-10]. In other words, it had certain conservation effect on moisture.

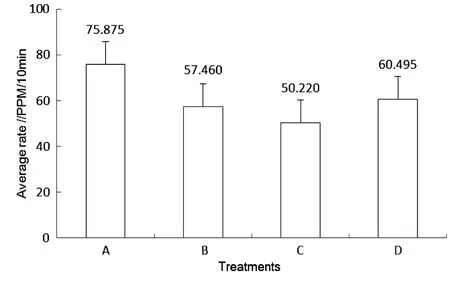

3.3. The effect of unequal amounts of biochar added on ammonia emission

The dynamic changing curve of ammonia emissions during the aerobic composting of chicken manure was shown in Fig. 3.

The ammonia emission of every group had a tendency to increase rapidly and then gradually decrease (Fig. 3). Based on the correlation analysis between ammonia emission concentration and temperature, it was concluded that the emission of ammonia was positively correlated with the temperature, which indicated that the higher the temperature, the faster the ammonia production.

From the microscopic perspective, it may well be that the microbial activity in the early days of composting was relatively strong so that it could be conducive to the degradation and transformation of nitrogenous organic materials. During the hightemperature period, the continuous high temperature speeded up the emission of ammonia; and in the late composting stage of this era or process, reduction of degradable organic matter, recession of a part of microbial activity and a gradual decline of heap temperature led to a fall in ammonia volatilization[11].Meanwhile, relatively low temperatures were also suitable for nitrifying bacteria, and this nitrification further lessened ammonia emissions[12].

Based on the influence of many factors such as temperature and microorganisms’ vital activities on the release of ammonia gas, this experiment was conducted to reduce ammonia volatilization loss by adding different proportions of biochar during the composting of chicken manure and to explore the nitrogen conservation effect of different amounts of biochar applied to chicken manure fermentation.In accordance with the double analyses of both experimental data obtained and the graphing of ammonia emissions in Fig. 3, it was not difficult to see the ammonia emission patterns in the composting process: Q(C)<Q(B)<Q(D). In other words, the conservation effect of nitrogen in Treatment Group C (added biochar at 20%) was optimum. Treatment Group D (added biochar at 30%) featured a certain conservation effect of nitrogen compared with Control Group A, but its final anticipated effect was not as good as that of the Treatment Group C. The leading reason may be that there was much more biochar added to the chicken manure, which greatly improved the aeration of the composting heap, excessively increasing the microbial available carbon source and even overly intensifying the microorganisms’ vital activities. Thus, the fermentation temperature was too high, causing the increasing temperature to promote ammonia volatilization, which counteracted the immobilized effects of microorganisms on ammonium nitrogen and nitrate nitrogen[13].

In addition, within the first 20 d of the initial stage of composting when the intensity of ammonia release was relatively concentrated and intense, the rates of ammonia release from every treatment were compared (Fig. 4). It was found that the average rate of ammonia release decreased separately from 75.875 PPM/10min (Control Group A) to 57.460 PPM/10min(Treatment Group B), to 50.220 PPM/10min(Treatment Group C) and to 60.495 PPM/10min(Treatment Group D). Apparently, adding biochar enabled the rate of ammonia release to be significantly inhibited, but the inhibitory effect of Treatment Group C was more pronounced. To some degree, it was shown that the nitrogen conservation efficacy of biochar in the aerobic composting of chicken manure was closely related to its application amount.

Fig. 4 Average rate of ammonia volatile release after different treatments (1~20 d)

3.4. Nutrient analysis and comparison of chicken manure composting in different treatments

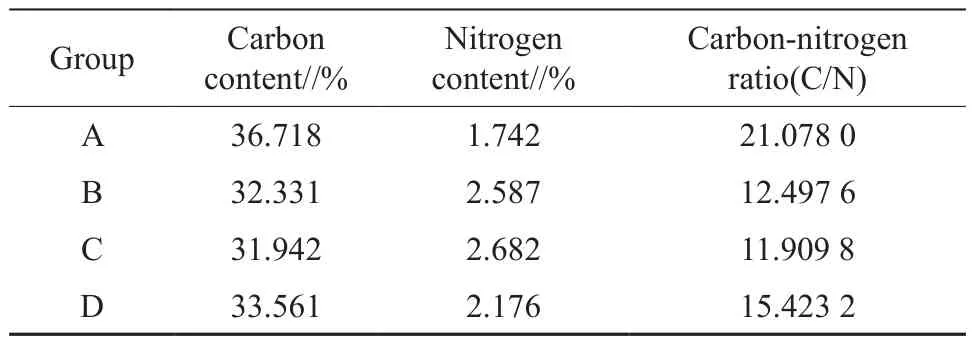

Unequal biochar amounts were added to the same organic substrate for the aerobic fermentation test. After 40 d, the content of carbon and nitrogen in each corresponding product was measured. The final carbon-nitrogen ratio of every treatment group with biochar added was obviously less than that of the control group, and the difference was significant (P<0.05); but in the nitrogen content of the composting products obtained, Treatment C was the highest,followed by Treatment B, Treatment D, and Control Group A, in the order (Table 3); and this showed that biochar had good nitrogen retention, the ability of biochar to conserve nitrogen was closely linked to the biochar application amount under the consistent condition of other factors, and an addition of biochar at 20% had the best nitrogen conservation during the composting of chicken manure.

Table 3 Content of nutrients in composting materials

What’s more, the nitrogen loss rates of Treatment Groups A, B, C and D were 28.1%, 21.7%, 20.8% and 23.6%, respectively, and that of Treatment Groups B,C and D were obviously lower than that of the Control Group A; but the nitrogen loss rates of all the treatment groups showed an irregular trend when the biochar application amount increased. Compared with the Control Group A, the nitrogen loss rates of Treatment Groups B, C and D decreased by 6.4%, 7.3% and 4.5%, respectively; namely, W(C)>W(wǎng)(B)>W(wǎng)(D). The statistical analysis showed that the amount of added biochar had a significant impact on the nitrogen loss rate of the compost heap.

4. Discussion

4.1. Influence of adding biochar on the process of composting substrate

In the aerobic composting process, temperature is the most direct indicator for the level of composting maturity. While temperature is affected by microbial activities, temperature also determines the course of microbial activities that can deviate from the norm[14]. The study showed that heap temperatures of the rest, except for the Treatment Group C, failed to reach the composting maturity index according to the hygienic standard for fecal decontamination. But more obviously, the maximum temperature of each treatment group with biochar was higher than that of the control group, and the time to reach the maximum temperature was also earlier than that of the control group, which means that adding the appropriate amount of biochar to chicken manure would help improve the heap temperature and accelerate the process of composting maturity. The abundant pore structure of biochar provided a good place for the spread and reproduction of microorganisms, and was also conducive to the transmission of oxygen, and the activity, the metabolism and heat-producing ability of microorganisms, and the temperature rise and the composting time shortening[15].

Currently, there have been few reports on the effects of biochar addition levels on the composting temperature at home and abroad. Many authors think that the activities and propagation of microbial populations depend to a greater extent on the content of nutrient elements and their equilibrium relationship.This conception is based on the theory of composting under accumulative temperature proposed by CHEN T B[16]and the relationship between the applied amount of biochar and composting heap temperature reported by WANG H H[17]. Based on the mass of dry material in the control group, the biochar in the treatments groups was designed as a percentage accounting for the control’s dry mass. It was not difficult to determine that the organic carbon content of biochar was relatively high and its total nitrogen content was low. So, although the microbial environment in the compost heap could be improved by increasing the heap biochar content, the carbon-nitrogen ratio of the compost heap was significantly elevated and the supply of nitrogen source was insufficient,which inhibited the further expansion of microbial populations and eventually caused the temperature rise to go down.

4.2. Dynamic changes of heap moisture during composting

The moisture of each group during the composting presented a downward trend. Nevertheless,with the exception of Control Group A, the decline was not significant in each treatment group. The main reason may be that biochar is of the property of a strong water-conservation agent. The micropore structure is easily formed during the preparation process of biochar. When these micropores are prone to expanding owing to heat, quite a few cracks at different pore sizes take shape, and some pore surfaces are ablated too. Additionally, there are incomplete structures, and the presence of involatile solids could form such oxygen-containing functional groups as carboxyl, hydroxyl and lactone[18-19]. As a result,the situation just described gives biochar extremely good hydrophilicity, thereby enhancing the ability of biochar to hold heap moisture.

4.3. Differences in nitrogen content between groups

Under the premise that the original carbonnitrogen ratios in every group remain basically consistent and after a period of aerobic composting treatment, chicken manure in some groups could reach the state of composting maturity, but some fell short of the compost-ready goal. For the compost products obtained, the nitrogen content of every group changed like W(C)>W(wǎng)(B)>W(wǎng)(D)>W(wǎng)(A) (Table 3), indicating that the amount of biochar added may affect the strength of ammonia emissions from the compost heaps, for which there may be three reasons as follows. First, biochar could physically absorb ammonia gas through its pore structure and chemically take in ammonium nitrogen via its ionic bonds,thereby slowing the volatilization of ammonia gas to achieve the nitrogen retention effect[20-21]. Second,biochar might contain volatile compounds such as ethylene that reduced the amount and activity of microorganisms if only the biochar application amount was inclined to be superfluous within a reasonable limit[22]. Third, an extreme amount of added biochar may bring about excessive moisture and compaction of raw materials, which prevented gas exchange and restrained the growth and reproduction of microorganisms, leading to instability of the aerobic composting process. Under these circumstances, when the amount of biochar added increased, the dynamic balance of emission and absorption gradually shifted toward the discharge end. However, the specific action mechanism needs further study.

5. Conclusions

In this study, dynamic changes of the key parameters of aerobic composting with only 10%,20% and 30% biochar were tested on the effect of the biochar addition amount on some crucial indicators such as ammonia emission during the aerobic composting. The aerobic composting experiment with chicken manure plus biochar was carried out with advantage of laboratory composting equipment and related apparatuses. Based on experimental data processing as well as physicochemical property analysis, the addition of biochar could help degrade organic matter in chicken manure, improve water conservation within the biochar mix and reduce ammonia emissions and nitrogen loss during the aerobic composting. And both reasonable proportion of raw materials and moderate oxygen supply could ensure safe and high-quality utilization of chicken manure.

Every treatment group in the experiment experienced three stages: the temperature raising period, the high temperature period and the cooling maturity period. The time to reach the maximum temperature of each treatment group with biochar was less than that of the control group without biochar.Among them, Treatment Group C with biochar added at 20% was the first to reach the highest temperature 52.5℃ on the 10thday, due to achieving the fastest temperature rise and the top temperature.

Change took place in the heap moisture.During the composting fermentation, water content of Treatment Groups B, C and D was markedly higher than that of Control Group A. However, the differences in moisture among B, C and D was not remarkable or basically the same, which was in line with DUGAN’s testing results[23].

Through a comprehensive analysis of ammonia emission and the nutrient components of the composting product, it was found that, when the proportion of biochar addition was 20%, nitrogen loss was least during the composting; biochar had the best nitrogen conservation effect; and the release rate of ammonia was the fastest in the initial stage of aerobic composting, which was the key period for curbing nitrogen loss.

In conclusion, adding the proper proportion of biochar could exert positive effects on both ammonia emission reduction and nitrogen conservation during the aerobic composting of chicken manure.

Agricultural Science & Technology2018年3期

Agricultural Science & Technology2018年3期

- Agricultural Science & Technology的其它文章

- Review of Factors Affecting the Yield and Quality of Corn Silage

- Phthalate Esters Biodegradation by Fusarium Oxysporum in Vegetable Soil

- One-off Mechanized Fertilization for Maize in Semiarid Area of Jilin Province

- Multiple Shoots Propagation with Bioreactor Culture of Labisia pumila (Bl.) F. Vill.

- Tolerance to Iron-Deficiency Stress of Three Apple Rootstock Species in Hydroponic System

- Genetic Similarity Analysis of Hunan Rice Landraces with Same or Similar Name in Household and Genebank Conservations