Ozone generation enhanced by silica catalyst in packed-bed DBD reactor

Xin ZENG (曾鑫), Yafang ZHANG (章亞芳), Liangyin GUO (郭良銀),Wenquan GU (古文泉), Ping YUAN (袁萍) and Linsheng WEI (魏林生)

School of Resources Environmental & Chemical Engineering, Nanchang University, Nanchang 330031,People’s Republic of China

Abstract In this paper,three dielectric barrier discharge(DBD)configurations,which were plain DBD with no packing,DBD with packed pure quartz fibers and DBD with packed loaded quartz fibers,were employed to investigate the effect and catalytic mechanism of catalyst materials in a packed-bed ozone generator.From the experimental results, it was clear that the DBD configuration with packed pure fibers and packed loaded fibers promotes ozone generation.For the packed-bed reactor,ozone concentration and ozone yield were enhanced by an increase of electric field in the discharge gap with the packed-bed effect.Meanwhile,the enhancement of ozone concentration and yield for the DBD reactor packed by loaded fibers with silica nanoparticles was due to the catalysis of silica nanoparticles on the fiber surface.The adsorption of silica nanoparticles on the fiber surface can prolong the retention time of active species and enhance surface reactions.

Keywords: DBD, ozone generation, packed-bed reactor, silica catalysis, surface reaction

1.Introduction

It is well known that ozone is one of the most environmentally friendly oxidizing agents and it has been widely used in various applications, such as drinking water disinfection, indoor air cleaning and sewage,and flue gas treatment.Ozone generation based on dielectric barrier discharge (DBD) has great advantages over other methods and it has become the main method used in commercial ozone generators.In recent years, many researchers have tried to increase ozone generation efficiency by using different ozone generation mechanisms [1–3], electrode materials[4],discharge chamber structures[5,6],power supplies [7], gas parameters and flow patterns [8–10].Unfortunately, the ozone yield is much lower than the theoretical value of 1226 g kW?1h?1in pure oxygen [11].

The usage of dielectric packing inside the discharge gap could be another way of enhancing ozone generation efficiency.Therefore,some scholars have tried to employ packedbed DBD reactor to increase ozone generation efficiency.Al-Abdulyet alinvestigated the effect of reactor arrangement,feed gas flow rate, coolant temperature, input power and dielectric material on ozone generation [12].Qinet alresearched the impact of gas source in a packed-bed DBD ozone generator [13].Schmidt-Szatowski, Jodziset alfound that packing SiO2can improve ozone generation efficiency[14–16].Packing particles of glass, Al2O3and γ-Al2O3has also been found to improve ozone concentration and ozone yield [17–19].Ozone generation enhanced by a loaded silica nanoparticle ceramic plate in a parallel-plate DBD reactor was demonstrated in our previous study [20].However,at present,there are no investigations of the loaded silica nanoparticles fiber catalyst effect and mechanism in packed-bed reactors.

Based on the situation described above, the same quality pure quartz fibers and quartz fibers loaded with silica nanoparticles were packed in the discharge gap to investigate its catalyst effect and mechanism.

2.Experimental setup

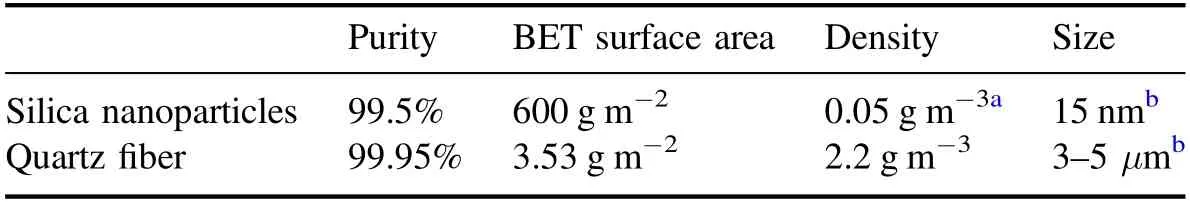

Table 1.Details of the silica nanoparticles and quartz fiber.

In this study, the loaded fibers were prepared by the wet-impregnation method.Typically, silica nanoparticles(MH-SiO2-15, Nanjing Emperor Nano Material Co.LTD,China) were prepared into sol by the physical dispersion method.Subsequently, quartz fiber (XH-SYM, ShanghaiXinhu Inc.,China)was immersed in silica colloidal solution for 10 h and dried at room temperature.Finally, the silica nanoparticles were fixed on the surface of the quartz fiber by hightemperature sintering at 800 °C for 4 h.Details of the materials are presented in table 1.

The experimental setup is shown in figure 1.The parallelplate reactor consists of an electrode system and a heat-dissipating system that includes upper and lower dissipation fins.The valid discharge volume of 120 mm×90 mm×1 mm for the reactor is packed with loaded and unloaded fibers.High pure oxygen (99.999%; containing N2< 5 ppm,H2O < 2 ppm, CO + CO2< 0.4 ppm) was controlled to flow from the oxygen cylinder to the discharge space by a mass flow controller (MFC DF-07, QiXingHuachuang Inc.,China).A high-voltage high-frequency AC power supply(CTP-2000K, Nanjing Suman Electronic Inc., China) was used.Electrical characteristics of the discharge and ozone concentration were measured by using a Tektronix oscilloscope (MDO3034, 350 MHz, 2.5 GS s?1, Tektronix, USA)and an ozone analyzer (Mini-Hicon, IN USA Inc., USA),respectively.

In the experiment, the gas circuit was first flushed with high pure oxygen of 1 SLPM (standard liter per minute) for half an hour, and the applied voltage (U0) and current (I0) of the ozone reactor were sampled by a high-voltage probe(P6015A, 75 MHz, Tektronix, USA) and a current monitor(model 2878, 200 MHz, Pearson, USA), respectively.The discharge power deposited into the reactor was characterized by using the Lissajous figure method, which was calculated by the equation ofrepresents the area of theU0?UcLissagous figure.Sampled by a passive voltage probe,Ucwas the voltage drop at both ends of a non-inductive capacitor (0.47 μF) which was installed between the grounded and grounding electrodes.

3.Results and discussion

3.1.Electrical characteristic

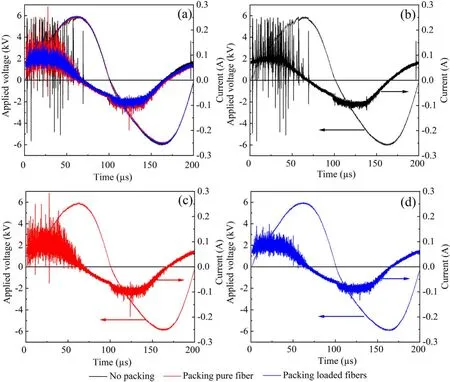

The electrical signal for the applied voltage and total current of the discharge with or without packing is shown in figure 2.For DBD with no packing, the total current waveforms are quasisinusoidal with numerous current pulses per half cycle of the applied voltage.These current pulses correspond to transient filamentary micro-discharges which are randomly distributed in time and space over the dielectric surface.For the packed DBD, the quartz fibers are fully packed into the discharge gap, filaments can only be generated in the small gap between the fiber–fiber and the fiber–dielectric plate,while a surface discharge can be formed on the surface of fibers near the contact points between the fibers.Therefore,packing pure fibers or loaded fibers into the discharge gap introduces a typical packed-bed effect, which leads to a transition in the discharge behavior from a typical filamentary microdischarge to a combination of surface discharge and filamentary microdischarge [21].

Figure 2.Electrical signals for three DBD configurations (6 kV, 5 kHz).

Comparison of figures 2(c)and(d)shows that,in the case of packing loaded fibers, the amplitude of several current spikes is small in comparison with that of packing pure fibers,which indicates that the intensity of the current pulse has been weakened.This is because silica nanoparticles loaded in the fiber surface are beneficial for the discharge streamer propagation on the fiber surface, which leads to a decrease of the current peak.A similar observation was made by Kim and Ogata [22].

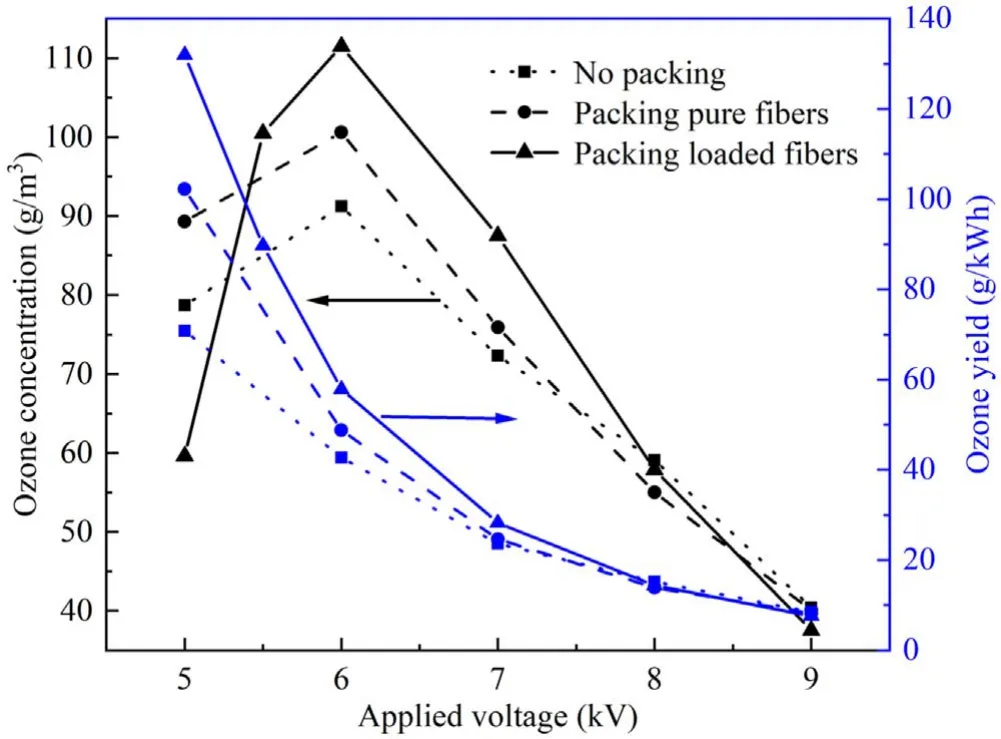

3.2.Influence of applied voltage

The applied voltage has an important influence on ozone concentration and yield.It is clear from figure 3 that ozone concentration increases first and then decreases in all three packed configurations when the applied voltage increases from 5.0 kV to 9.0 kV, and there is an optimal applied voltage to maximize the ozone concentration.This is because the increased applied voltage not only generates more high-energy electrons but also generates more thermal energy.The effect of the high-energy electrons is dominant at low applied voltage, which benefits ozone generation.With the increase of applied voltage, ozone decomposition due to the increase of gas temperature resulting from thermal energy will gradually dominate.Therefore, ozone yield decreases gradually.

Figure 3.Ozone concentration and yield as a function of applied voltage (5 kHz, 1 SLPM).

Figure 4.Ozone concentration and yield as a function of applied frequency (6 kV, 4 SLPM).

It can be seen from figure 3 that packing catalytic materials has an obvious effect on ozone concentration and yield.When the applied voltage is 6 kV.The ozone concentrations of packing loaded fibers, pure fibers and no packing are 111.5 g m?3, 100.6 g m?3and 91.2 g m?3,respectively.Meanwhile, the ozone yields are 57.85 ±2.88 g kW?1h?1, 48.77 ± 2.46 g kW?1h?1and 42.70 ±2.11 g kW?1h?1, respectively.Compared with no packing,the ozone concentration and yield of packed pure fibers increased by 10.31% and 14.22%, and the packed loaded fibers increased to 22.26% and 35.49%, respectively.When the applied voltage is 5 kV,the ozone yield of packed loaded fibers is even higher (86.2%) than that of unpacked fibers.

As shown in figure 3,when the applied voltage is higher than 8 kV, the ozone concentration of the DBD with full packing is lower than that of no packing.This is because the heat dissipation performance of the packed-bed reactor is worse than that of the parallel-plate reactor, which results in the higher temperature of the packed-bed reactor and accelerated decomposition of ozone [18].

3.3.Influence of applied frequency

The effect of frequency on ozone concentration and ozone yield is shown in figure 4.Higher frequency leads to higher discharge power and more thermal energy, which affects ozone concentration and yield.It is clear from the figure that ozone concentration increases with a gradual decreasing rate and ozone yield reduces when the applied frequency rises for all three DBD configurations.Compared with no packing,the ozone concentration and yield of packing pure fibers increased 26.04% to 57.6 g m?3and 30.64% to 111.81 g kW?1h?1.Similarly, the DBD with packing loaded fibers increases the ozone concentration and yield by 33.48% to 61 g m?3and 47.93% to 126.61 g kW?1h?1.

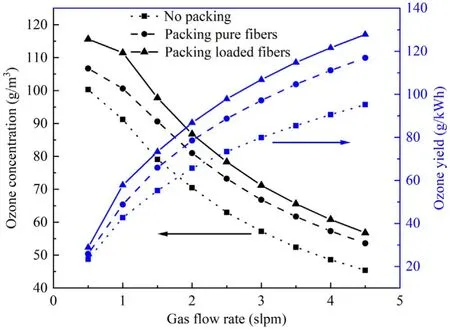

3.4.Influence of applied gas flow rate

Figure 5.Ozone concentration and yield as a function of gas flow rate (5 kHz, 6 kV).

As shown in figure 5, the ozone concentration reduces while the ozone yield increases with the increase of the gas flow rate in all three DBD configurations.Such changes were also observed in previous studies [23].The collision probability of oxygen molecules and electrons decreases due to the short residence time of oxygen in the discharge gap with the increase of gas flow rate during the process of ozone generation.This results in a gradual decrease in ozone concentration.Meanwhile, ozone yield increases at a low gas temperature with a higher gas flow rate.It is clear from figure 5 that packing quartz fibers in the discharge gap can catalyze the generation of ozone,especially packing loaded fiber.When the oxygen flow rate is 3.5 SLPM, the ozone concentration and ozone yield of packing pure fibers increase by about 17.15% and 22.54%,respectively, compared with no packing.Meanwhile, packing loaded fibers increased 25.19% and 34.39%, respectively.

3.5.Discussion

It is clear from the experimental results that packing catalyst material is beneficial for ozone generation, especially for the configuration of packing loaded fibers.This section will evaluate the enhanced ozone generation from three aspects:the influence of packing configuration on the discharge characteristics of the packed-bed DBD reactor, the silica catalyst and their interaction.

3.5.1.Discharge characteristics.The electric field is enhanced at the contact points between the fiber–fiber and fiber–dielectric barriers in the packed-bed DBD reactor due to the increase of charge deposition resulting from more effective polarization at these points [21, 24].Higher electric field strength means higher electron energy.Gadkari and Gu reported that the electron energy in their parallel-plate DBD reactor without any packing was 2.19 eV; a higher electron energy of 7.33 eV was achieved when the reactor was fully packed.The latter is 3.3 times higher than the former [25].

Electron energy is an important parameter for ozone generation.The higher energy of the electron,the more energy will become available for O2decomposition, which will generate important species such as singlet-state oxygen (O1D)and triplet-state oxygen(O3P)for ozone generation.Therefore,DBD with a fully packed configuration has higher ozone concentration and ozone yield than DBD with no packing.

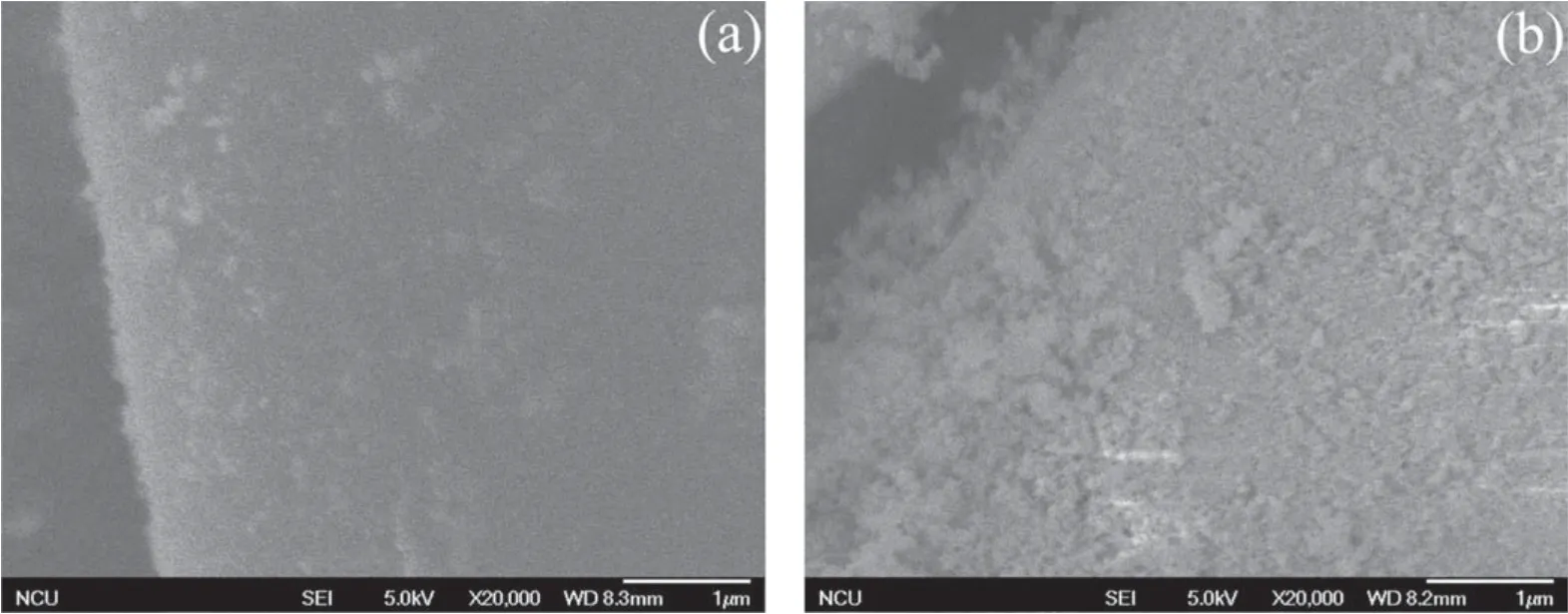

Figure 6.Scanning electron microscopy images of the pure and loaded fibers before discharge: (a) pure fibers; (b) loaded fibers.

3.5.2.Silica catalyst.For the plain DBD ozone generators with no packing, the three-body collision reaction(equation (1)) is considered to be the major reaction for ozone formation [26–28].Additionally, the impact of the surface reaction (equation (2)) is often overlooked due to its low reaction and ozone yield.

From the above experimental results,it is clear that silica film has a catalytic effect on ozone generation.The quartz fibers and loaded fibers were studied by scanning electron microscopy.Comparison of figures 6(a) and (b) shows that the surfaces of the pure fibers are relatively smooth.In contrast, the surfaces of the loaded fibers are rough because silica nanoparticles have been loaded onto the surface of the quartz fibers by impregnation.Furthermore, the particle size of the silica nanoparticles attached onto the surface is much smaller than that of quartz fibers.Thus, a loaded fiber has a higher specific surface area.This is consistent with the results of the Brunauer–Emmett–Teller(BET)surface area tests of the pure quartz and loaded fibers.The BET surface areas of the quartz and loaded fibers were determined to be 3.53 m2g?1and 90.81 m2g?1, respectively.In addition, the specific surface area of the dielectric was 2.00 m2g?1.A higher specific surface area means stronger physical adsorption [29].

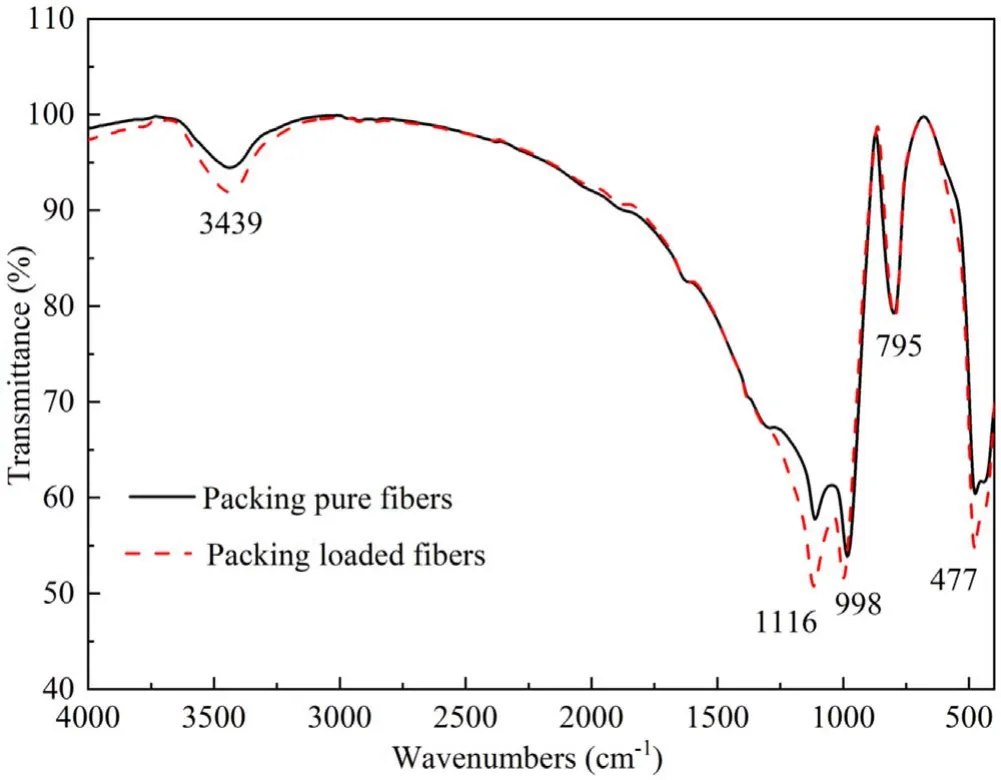

To further confirm the existence of silica nanoparticles on the surface of the quartz fibers, Fourier transform infrared spectroscopy(FTIR)was conducted as shown in figure 7.As shown in figure 7, chemical bonds of Si–O (4477 cm?1,795 cm?1), Si–O–Si (998 cm?1, 1116 cm?1) and –OH(3439 cm?1) are observed in the FTIR spectrum figure,which confirms the existence of hydroxyl groups in the quartz fiber.There are more unsaturated bonds and hydroxyl groups on the surface of the loaded fiber those on the pure fiber.Subsequently, loaded fibers have stronger chemical adsorption than pure fibers.

Figure 7.FTIR spectrum of pure and loaded fibers after discharge.

In conclusion, loaded fibers have stronger adsorption(mainly including physical adsorption and chemical adsorption)than pure fibers.This means that DBD with packing pure fibers has a stronger absorption capacity than DBD with no packing, and DBD with packing loaded fibers has a stronger absorption capacity than packing pure fibers.A stronger adsorption capacity indicates that it can prolong the retention time of active species and enhance the surface reaction,which increases ozone generation efficiency.The detailed catalytic mechanism was discussed in our previous study [20].

3.5.3.Mutual promotion.The DBD reactor with a fully packed configuration has higher electron energy than the plain DBD reactor.Higher electron energy means more active species as singlet-state oxygen(O1D)and triplet-state oxygen(O3P) in the discharge gap, which are the most important species for ozone formation by the following reactions:

For plain DBD and DBD with packing pure fibers,(O1D)and(O3P)were de-excited quickly due to their short lifetimes.However, short-lived active species usually have high chemical sticking coefficients,which means that these species can be easily adsorbed and stabilized on the surface of the catalyst[30].Therefore,for DBD with packing loaded fibers,the retention of these short-lived active species will be prolonged owing to the stronger adsorption capacity of silica film.Meanwhile, loaded fibers can enhance the surface reaction at a gas–solid interface.

4.Conclusion

In summary, the packed-bed DBD reactor is highly efficient for producing ozone.In this paper, the effect of loaded and non-loaded quartz fibers with silica nanoparticles on ozone generation in a packed-bed DBD reactor has been investigated in detail.The efficiency of ozone generation was found to increase in the following order: no packing Acknowledgments This work is supported by National Natural Science Foundation of China (No.51867018), Jiangxi Province’s Major Subject Academic and Technical Leader Training Program-Leading Talent Project (No.20204BCJ22016), and the Innovation Fund Designed for Graduate Students of Jiangxi Province, China (No.YC2020-S118). ORCID iDs

Plasma Science and Technology2021年8期

Plasma Science and Technology2021年8期

- Plasma Science and Technology的其它文章

- Two-point model analysis of SOL plasma in EAST

- Line identification of boron and nitrogen emissions in extreme- and vacuumultraviolet wavelength ranges in the impurity powder dropping experiments of the Large Helical Device and its application to spectroscopic diagnostics

- Landau damping of twisted waves in Cairns distribution with anisotropic temperature

- Effects of magnetic field on electron power absorption in helicon fluid simulation

- Dependence of plasma structure and propagation on microwave amplitude and frequency during breakdown of atmospheric pressure air

- Machine learning application to predict the electron temperature on the J-TEXT tokamak