Technical Standard System Construction Plan for Surfactants and Detergents in the“13th Five-year Plan” Period

Yao Chenzhi, Li Xiaohui

National Standardization Center for Surfactant/Detergent, China

Overview of industry development

Industry overview

A detergent is an important component of daily chemicals, and the detergent industry is an important industry involving people’s livelihood. The detergent industry is mainly comprised of domestic detergents, as well as, industrial and public facility detergents, covering surfactants, detergent builders, and the oleochemical industry raw materials for detergents. Domestic detergents are mainly used for personal care, food,textiles, and household hard surfaces; industrial and public facility detergents are mainly used for industrial cleaning, catering, hotels, and other public facilities.Surfactants are used in various industrial fields, including cleaning, cosmetics, petrochemical engineering, and printing & dyeing. In the detergent field, surfactants are the main active ingredient for synthetic detergents, with lower dosage, but indispensable, in other industrial fields.From each family to industry and to society, detergents are closely linked to the life of common people, industrial production and urban & rural hygiene.

Development situation and trend

The “12thFive-year Plan” period is a crucial period for China to build a well-off society in an all-round way,to deepen reform and opening-up, and to accelerate transformation of the economic development mode.During this period, the detergent consumption concept of consumers has significantly changed. Consumers are no longer satisfied with detergency guarantees and cheap price. More and more consumers tend to demand detergent differentiation and functionalization, thus promoting technical improvement of the detergent industry. The detergent industry has formed three category systems, i.e. personal care products, household cleaning products and industrial and public facility cleaning products. With respect to product shape, in addition to the normal powder and massive detergents,easy-to-use, energy-saving and cost-reducing liquid products are rapidly growing and developing. In addition to efficacy, there is greater emphasis on safety and environmental protection, energy saving and water saving during production, as well as, reduction of energy consumption and material consumption during transportation.

With respect to demand for terminal product functionalization and differentiation, surfactant raw materials have become large-scale and intensive in traditional bulk varieties, significantly improved in equipment and technology; products have reached international advanced levels, so the bulk raw materials can be self-sufficient. Meanwhile, under support from the national sci-tech support plan, the new functional raw materials, applicable to detergents, have broken through key technologies of surfactant partial catalysis,device and molecular design to realize AEG and MES ten thousand ton class industrialization, playing an active role in optimizing the formulation of detergents.Technical progress and innovation have promoted steady and rapid development of the industry. China has become the world’s leading manufacturer of detergents.

Development goals of the “13th Five-year Plan”period

Surfactants and detergent builders start from being“l(fā)ow-carbon ecological”, and “industrial value-based”detergents, start from being “concentrated, functional,water-saving and diversified”, as well as, “environmentallyfriendly and safe”. Production processes should be low-carbon and environmentally-friendly, outdated capacity should be obsolete, and improvement in rate of operation should be promoted. Construction of a safety standardization system, environmental management systems and occupational health systems should be vigorously promoted to improve the enterprise’s awareness of responsibility for safety, environmental protection and social morality, promote industrial upgrading, and promote steady development of our national economy.

We should actively promote the comprehensive,innovation chain for fundamental, frontier research,key generic technology, and industrial demonstrations through studies on efficient catalysis and clean technology, with natural renewable resources as the raw materials to develop the concentrated, low-foaming and easy-to-rinse environmentally-friendly surfactants and detergent builders safe for a human body and ecological environment and applicable to detergents.We should utilize the new safe and environmentallyfriendly surfactants and detergent builders to develop concentrated, water-saving, environmentally-friendly and safe detergents; we should comprehensively improve production technology, packaging, transportation and other links to fully realize energy-saving and costreducing manufacturing of detergents, thus promoting low-carbon action and sustainable development of the detergent industry.

Standard system framework

Concepts and principles for construction of standard system

Surfactant and detergent belong to the daily chemical product industry in the GB/T 4757-2011 Industrial Classification for National Economical Activities.Therefore, the top layer of the standards system is daily chemical products. Surfactant and detergent fields are the second and third layers of the standards system framework, respectively.

Frame structure and description of the standards system

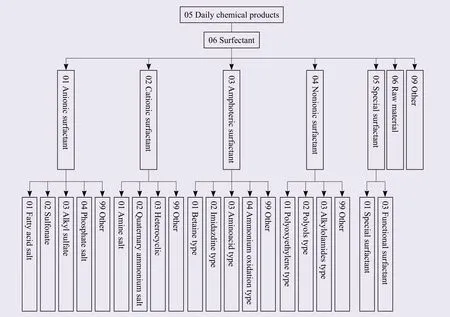

Figure 1 shows for the standard system framework of the surfactant field.

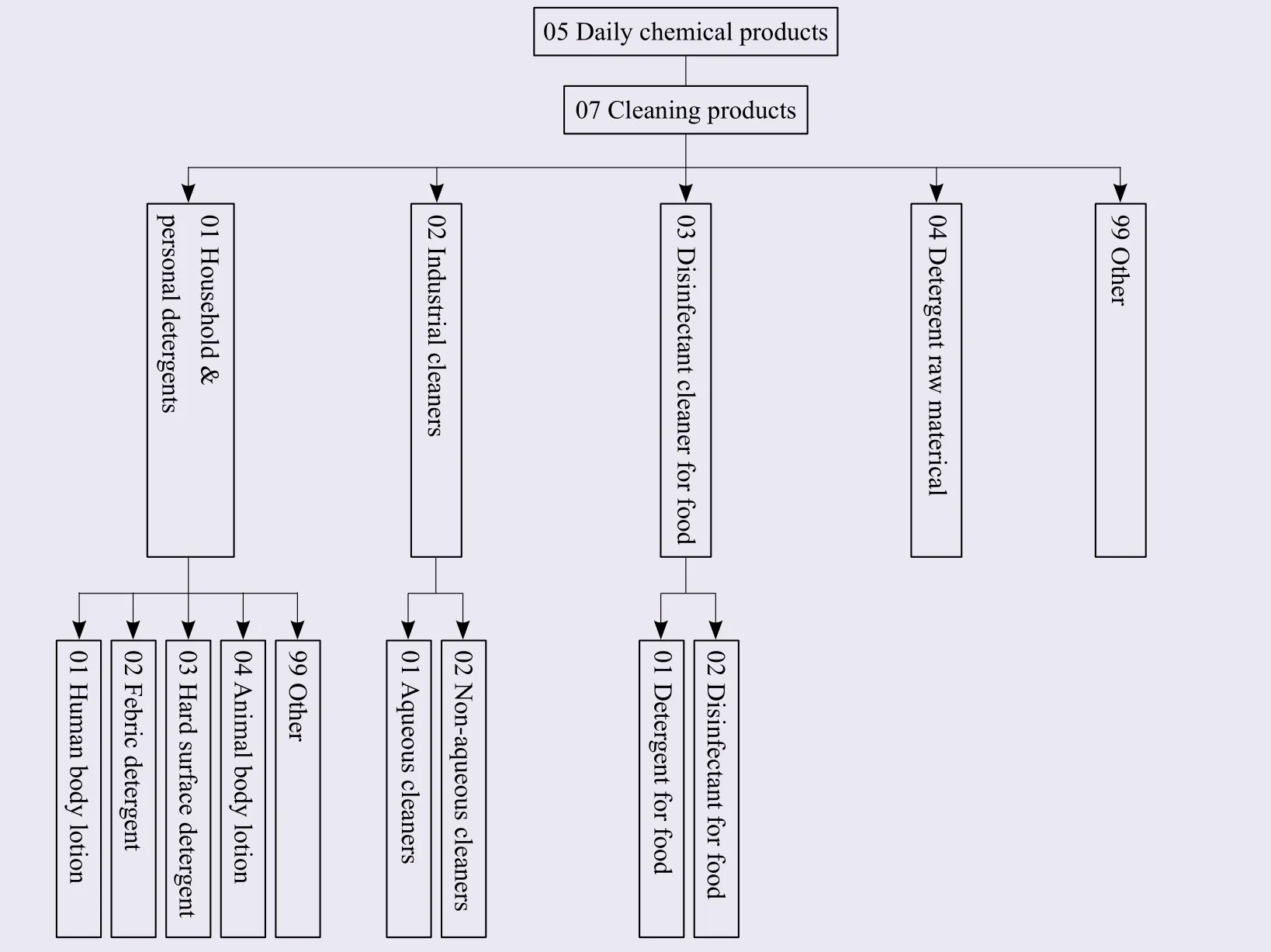

Figure 2 shows for the standard system framework of the detergent field.

Rules for numbering of the standard system table

06 surfactant (big class), based on the dissociative nature of polar group (middle class), is divided into 01 anionic surfactant, 02 cationic surfactant, 03 zwitterionic surfactant, 04 non-ionic surfactant, and additionally, 05 special surfactant, 06 raw material, and 99 others. The middle class is also divided into small class, based on different molecular structures (Figure 1).

07 detergent (big class), based on the product application scope (middle class), is divided into 01 family and personal detergent, 02 industrial detergent, 03 food disinfectant,and additionally, 04 detergent raw material, and 99 others.The middle class is also divided into a small class based on different applicable objects (Figure 2).

Current standard system

Existing standards and under-research plans

Figure 1. Standard system framework of surfactant

Figure 2. Standard system framework of detergent

The surfactant and detergent fields involve 67 current national standards, and 83 industrial standards, totaling 150 standards, including 81 product standards, 62 method standards, and 7 basic general and management standards.The surfactant and detergent fields involve planned projects of 38 under-research standards, including 18 product standards, 19 method standards and 1 basic general standard.

After rapid development in the past three decades, the standards for surfactant and detergent fields have been increased year by year. At present, main method standards have reached the international general level, while some standards have reached the international advanced level and have been transformed to international standards. Product standards had been formalated with own characteristics, and the technical indicators are consistent with the actual situation of Chinese products.The requirements for safety indicators are relatively strict, comparable to, or even stricter than, the standard requirements of foreign advanced countries, ensuring product safety, beneficial to the health and safety of consumers, as well as, environmental protection and sustainable development.

The existing problem is that, as displayed by the coverage of existing standards, development of domestic standards is uneven, reflected in the severe shortage of standards for the industrial and public facility detergent and food disinfectant fields; basic general standards are relatively lacking and lagging; the existing standards cannot meet modern industrial demands in the product raw material safety and market management.

Standard internationalization

International standards conversion and foreign advanced standards.The international standard organization in field is ISO/TC 91—Surfactant Technical Committee.

ISO/TC91 has enacted and released 78 international standards, which are test methods or basic general standards, where 64 standards have been transformed to national standards, including 12 standards of IDT conversion, and 52 standards of MOD conversion.One standard is being converted, 3 standards are to be converted, and 10 standards are not suitable for conversion, with the conversion rate of 94%. Nonconversion is mainly due to non-product and method inapplicability in China.

Over the years, international standards and foreign advanced standards have been actively used in this field, and meanwhile, national standards and industrial standards of our own characteristics are also being developed. National standards for human body and the environment are, basically, synchronous with foreign advanced standards, and meanwhile, based on peopleoriented purposes, national standards are comparable to,or even stricter than, the foreign advanced standards in terms of requirements for safety indicators, e.g. methyl alcohol, formaldehyde, arsenic, mercury, heavy metal,free caustic alkali, total phosphorus pentoxide, biological degradability, total bacterial count, coliform, sterilization rate, and antibacterial rate.

With respect to the possible effect of surfactants and detergents on the environment and human body, many related national standards have been developed in China,where the Gas Chromatography for Determination of Residual Dioxane in Surfactants, the Determination of Residual Chloroacetic Acid (Chloracetate) in Surfactants,and many other national standards, have reached the international advanced level. On this basis, we have actively applied for new project approvals for 4 international standards, which have been released in 2014~2015.

Participating and leading the development of international standards and foreign advanced standards.In 2014~2015, 4 international standards led by, China were released, achieving zero breakthroughs where China leads development of international standards in this field. The 4 international standards are converted from, or synchronously developed from the current national standards, reflecting continuous improvement of the overall level of standards in this field. Meanwhile, 3 international standards, led by China, are under research,which will be completed and released during the “13thFive-year Plan” period.

Foreign language translation of national standards.In response to the “One Belt One Road” strategy of the Chinese Government, to promote the national standards to “go out” boosting the development of the industry,7 national standards on surfactant and detergent have been translated becoming a landmark event for national standards to reach out to the world. On June 23, 2016, the Director of Singapore Standards Board, officially, wrote to request China National Standardization Management Committee apply some of the contents of national standard GB/T 13173 - 2008 in development of the standards for “l(fā)iquid soap”, highlighting the international influence of national standards.

Key fields to be developed in the “13th Five-year Plan”

The “Made in China 2025”, and the “Equipment Manufacturing Industry Standardization and Quality Improvement Plan” will be implemented to comprehensively carry out the green manufacturing strategic task, to implement green manufacturing standards improvement, and to accelerate development and revision of standards for green products in this field,thus promoting green transformation and upgrading of the manufacturing industry.

The implementation of “Consumer Goods Safety Standardization Project” among the ten major projects proposed in the National Standardization System Construction and Development Plan (2016~2020) will be promoted.

The improvement plan for “cosmetics and daily chemicals” in the Consumer Goods Standard and Quality Improvement Plan (2016~2020) will be implemented, to adapt to the diversified demands of consumers for product efficacy, perfect the detergent standard system, and develop the basic general standards, important product standards and test method standards to prevent toxic and harmful substances from being out of standards.

Development goals and main tasks of technical standard system in the “13th Five-year Plan”

Development goals and main tasks

Construction goals: The average age of standards shall be less than 5 years, the conversion rate of international standards shall be up to 95% or above, the conversion from national standards to international standards shall be continued, and the development of one international standard shall be proposed to promote improvement of overall technical level of standards. We shall implement the “Made in China 2025” in this field, develop one standard for green product evaluation, 5 standards for safety of consumer goods, and 5 standards for quality improvement of consumer goods, and complete one top mandatory standard in this field.

Main task: we shall develop standards for the green product evaluation of detergents, guidelines for raw material health risk assessment of detergents, the series of standards for disinfectants for food and tools and equipment in contact with food, the series of standards for biological materials for detergents, and mandatory national standards for safety technology specification of detergents to improve the transformation rate of international standards.

Key fields where standards shall be developed

Standards for green product evaluation.Along with consumers heightened awareness for green health, green and healthy daily necessities have become consumption hotspots; however, there is a lack of related standards in the domestic market, where product quality varies,occasionally bringing economic loss and health effects to consumers, greatly reducing public confidence in domestic products. The core concept of green products is to improve product quality, so as to, satisfy increasing demands in social production and people’s lives under the background of social and economic development in this new period. Standards for green product evaluation shall be established to promote the supply of high-end green products, so as to, adapt to and satisfy the emerging trend of green consumption.

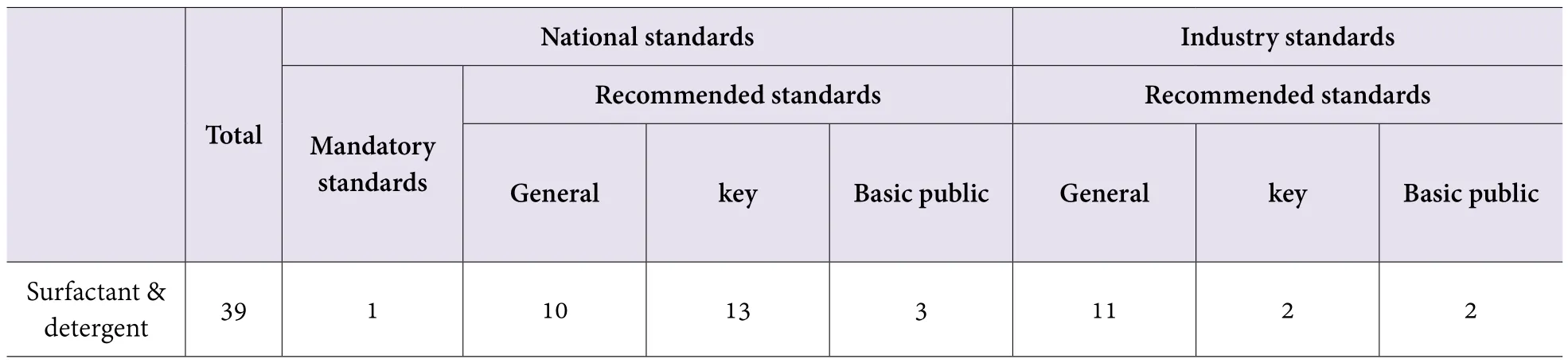

Table 1. Standard items which will be development and revised

The standards for green product evaluation of detergents shall be developed.

Guidelines for raw material health risk assessment of detergents, where the risk assessment system shall be established.We shall establish a risk assessment system for the safety of detergents, develop corresponding guidelines for health risk assessment, implement risk assessment for raw materials in the formulation of detergents, determine the limit for safe dosage, guide and specify product production and use, ensure the health of users, and improve safety standardization level of consumer goods.

The guidelines for raw material health risk assessment of detergents shall be developed.

Series of standards for disinfectants for food, food utensils and equipment.We shall develop a series of standards for food, tools, and equipment in contact with food by category, and specify quality specification,disinfection effect, and usage mode of disinfectants on the basis of the mandatory standard GB14930.2— 2012 National Standard for Food Safety—Disinfectants. Further standardization of production and use of such disinfectants plays an important role in safeguarding food safety, which has important significance for implementing the strategy of“Consumer Goods Safety Standardization Project”.

The product standards for chlorine-containing disinfectants, hydrogen peroxide disinfectants, peroxide disinfectants and guanidine disinfectants for food shall be developed.

Series of standards for biological materials for detergents.Chinese detergents are different from foreign detergents in formulation to some extent, due to different usages. Due to Chinese detergent formulations and washing habits, it is suitable to add some biological materials, mainly bio-enzymes. Detergents with the addition of bio-enzymes also have excellent performance in cold water washing environments.

Currently, about 50% of the detergents in China have the additive of bio-enzymes, which is mainly used to clean daily stains such as blood, oil, sweat and milk stains.

The product standards for detergent enzymes such as lipase, protease and amylase. We shall also develop performance evaluation methods for detergent enzymes shall be developed.

Mandatory national standards for safety technology specification of detergents.Based on the pre-evaluation conclusion of integration and simplification of 2016 mandatory national standards, we shall extract the safety requirements in the original mandatory national standards to integrate into the basic general mandatory standard with strong universality, and wide coverage in this field—Detergent Safety Technology Specification.

We shall also revise the GB/T 26396—2011 Detergent Safety Technology Specification as a mandatory standard.

Standard items to be developed and revised

The overall situation of standard items to be developed and revised during the “13thFive-year Plan” period shall be described, and the general standard items, key standard items and basic public welfare standard items shall be distinguished, and the years to be scheduled shall be identified (Table 1). Standard items to be revised for integration and simplification of mandatory standards and centralized review of recommended standards shall be included in a timely manner.

Summary

The technical standard system, construction in the “13thFive-year Plan” period in the surfactant and detergent fields centers on the “Made in China 2025” and other policies for key breakthroughs and overall improvement, highlight construction of green manufacturing, product safety and quality improvement standard systems to satisfy the increasing current demands for living environment and life quality, to improve product quality and safeguard the citizen life and health level. We shall accelerate product structure adjustment and optimization, and promote transformation to a green economy, to drive improvement of the overall technical level of the industry.

China Detergent & Cosmetics2018年1期

China Detergent & Cosmetics2018年1期

- China Detergent & Cosmetics的其它文章

- Reconstruction of 3D Skin Model and Its Application in Evaluation the Efficacy of Cosmetic Raw Materials and Active Intredients

- An In Vitro Biological Model for Evaluation of the Anti-Dandruff Performance of Hair Care Products

- Models for Assessing Pollution Damage of Asian Hair

- Technical Approaches and in-vitro Evaluation Methods for Scalp Care

- Regulation of Talcum Powder in Cosmetics at Home and Abroad

- A Summary on Chinese Daily Chemical Journals