Stability analysis of seabed strata and casing structure during the natural gas hydrates exploitation by depressurization in horizontal wells in South China Sea

Png-fi Xi , Lin Yang , Qian-yong Liang *, Xu-hui Zhang *, Liang-hua Zhang , Bin ZhangXiao-ing Lu , Hui-c H Xu-min Wu Yi-fi Dong

a Southern Marine Science and Engineering Guangdong Laboratory (Guangzhou), Guangzhou 511458, China

b Guangzhou Marine Geological Survey, China Geological Survey, Ministry of Natural Resources, Guangzhou 510760, China

c Institute of Mechanics, Chinese Academy of Sciences, Beijing 100190, China

d China University of Geosciences (Beijing), Beijing 100084, China

e University of Chinese Academy of Sciences, Beijing 100049, China

f National Engineering Research Center of Gas Hydrate Exploration and Development, Guangzhou 511400, China

1 Both authors contributed equally to the paper

Keywords:

Natural gas hydrates (NGHs)

Exploitation by depressurization

Horizontal well

Stratum subsidence

Shear failure

NGHs exploration trial engineering

Oil and gas exploration engineering

Shenhu Area

South China Sea

A B S T R A C T

Natural gas hydrates (NGHs) are a new type of clean energy with great development potential.However, it is urgent to achieve safe and economical NGHs development and utilization.This study established a physical model of the study area using the FLAC3D software based on the key parameters of the NGHs production test area in the South China Sea, including the depressurization method, and mechanical parameters of strata, NGHs occurrence characteristics, and the technological characteristics of horizontal wells.Moreover, this study explored the law of influences of the NGHs dissociation range on the stability of the overburden strata and the casing structure of a horizontal well.The results are as follows.With the dissociation of NGHs, the overburden strata of the NGHs dissociation zone subsided and formed funnelshaped zones and then gradually stabilized.However, the upper interface of the NGHs dissociation zone showed significant redistribution and discontinuity of stress.Specifically, distinct stress concentration and corresponding large deformation occurred in the build-up section of the horizontal well, which was thus prone to suffering shear failure.Moreover, apparent end effects occurred at the end of the horizontal well section and might cause the deformation and failure of the casing structure.Therefore, it is necessary to take measures in the build-up section and at the end of the horizontal section of the horizontal well to prevent damage and ensure the wellbore safety in the long-term NGHs exploitation.

1.Introduction

As a new type of clean energy, NGHs (also called flammable ice) have become a global hot topic due to their advantages such as wide distribution, high resource reserves,and high energy density (Collett TS, 2002; Solan ED, 2003).More than 90% of NGHs have been found in sandy or argillaceous seabed sediments (Johnson AH, 2011).However,it is still urgent to exploit marine NGHs in an economical,efficient, and safe manner.To accelerate the industrial development of NGHs, many countries including Japan have carried out multiple NGHs production tests in sea areas(Yamamoto K et al., 2014, 2019).China has also successfully conducted two production tests in the Shenhu Area in the South China Sea (Li JF et al., 2018; Ye JL et al., 2020; Su PB et al., 2021; Zhang XD et al., 2021).In the second production test of China in 2020, two world records were set using depressurization in horizontal wells, namely a total gas production of 86.14×104m3and an average daily gas production of 2.87×104m3(Ye JL et al., 2020).

Despite great development potential, NGHs are prone to cause environmental disasters.Once the stable environment of NGHs occurrence areas is destroyed, NGHs dissociation will produce a series of adverse effects, including excess pore pressure, the decrease in the effective stress of soils and the bearing capacity of strata, the possible liquefaction of seabed strata, and accidents such as wellbore instability and blowout.These effects will endanger the drilling platform and may even trigger seabed subsidence and landslides, which can cause disasters such as earthquakes and tsunamis (Rutqvist J and Moridis GJ, 2008; Liu CL et al., 2017; Lu XB et al.,2019).Therefore, to develop and utilize NGHs in a safe and eco-friendly manner, it is necessary to study the reservoir stability in the process of NGHs exploitation (Rutqvist J and Moridis GJ, 2008; Ning F et al., 2012; Liu LL et al., 2021).

Some researchers have investigated the stability of NGHs exploitation using numerical simulation software.Lu XB et al.(2010) simulated the NGHs exploitation through a vertical well using the ABAQUS software, revealing the impacts of the NGHs exploitation on the deformation of the production well and its surrounding soils.Wang J et al.(2017) simulated the eruption and failure of the overburden strata of NGHs reservoirs using the FLAC3Dsoftware.Rutqvist J and Moridis GJ (2008) simulated the changes in the seepage and stress fields in the NGHs exploitation through vertical and horizontal wells using the TOUGH+HYDRATE and FLAC3Dsoftware.They concluded that displacement tends to intensively occur at the wellhead and that vertical wells are safer than horizontal wells in NGHs exploitation.Previous studies on the stability of NGHs exploitation have mostly focused on vertical wells.However, compared with vertical wells, horizontal wells can significantly increase the contact area between the wellhead and NGHs reservoirs and achieve a high gas recovery and energy efficiency ratio.Therefore,NGHs exploitation using horizontal wells serves as an important potential mode for commercial NGHs exploitation.Moreover, few studies have been conducted on the stability of the NGHs exploitation using horizontal wells due to the complex geological conditions in the South China Sea (Sultan N, 2004; Wang SY et al., 2009; Zhang XH et al., 2011, 2014;Chen XD et al., 2016).

This study investigated the target NGHs reservoirs for production tests in the South China Sea.Based on the NGHs occurrence characteristics and the geomechanical parameters of reservoirs in the study area, this study investigated the stress and deformation characteristics of seabed strata, NGHs reservoirs, and soils surrounding the horizon well during the NGHs exploitation by depressurization using the FLAC3Dsoftware.Moreover, this study analyzed the law of influences of NGHs exploitation by depressurization on the stability of strata and casing structure, aiming to provide theoretical support for the safe and efficient development and utilization of NGHs.

2.Geological setting

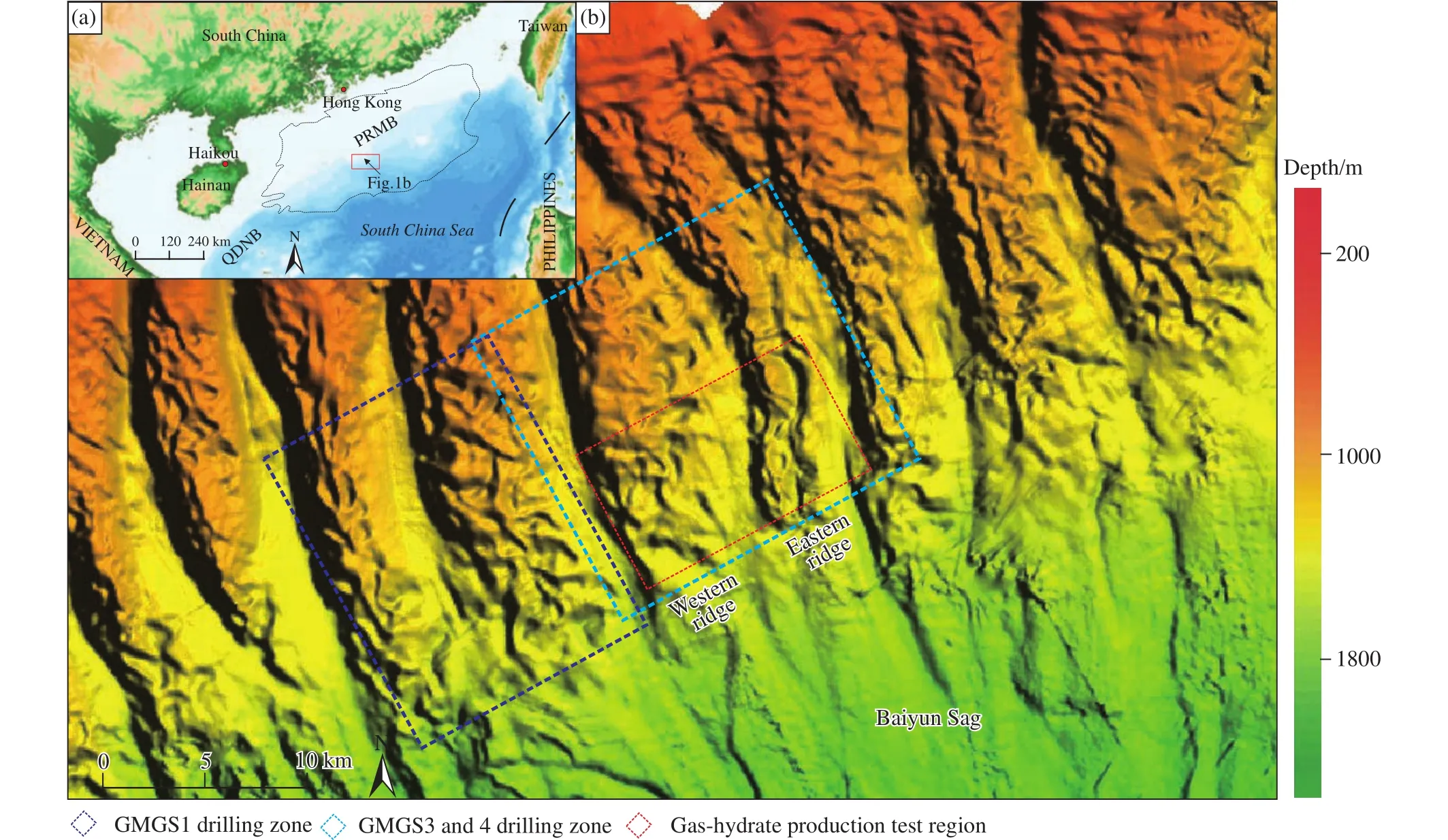

The study area is located near the southeastern Shenhu Shoal in the middle section of the continental slope of the northern South China Sea (Fig.1), with a seabed depth of 1000-1700 m.This area lies at the passive continental margin of the South China Sea.In terms of the geotectonic location, it lies in the Baiyun Sag of the Zhuer Depression in the deep-water area of the Pearl River Mouth Basin, showing the development of active faults, diapirs, gas chimneys, slumps,slope break zones of faults, and submarine sandy turbidites.These natural geological conditions are highly favorable for NGHs accumulation (Zhang W et al., 2017).

Fig.1.Map showing the geographical location of the study area.PRMB-Pearl River Mouth Basin; QDNB-Qiongdongnan Basin.

Sediments in the study area mainly include clayey silts and silty clay rich in paleontological fossils.The minerals in the sediments include quartz, illite, calcite, dolomite, chlorite,albite, K-feldspar, and pyrite.The sediments have evenly distributed pores with sheet-like and curved lamellar pore throats, a pore size of 500 nm - 20 um, porosity of 33%-55%,and effective permeability of 0.2-20 mD (Kang DJ et al.,2020; Ye JL et al., 2020; Wu NY et al., 2007).Based on the results from the downhole piezocone penetration tests of strata in the study area conducted by the China Geological Survey, the shear strength of strata at a depth of 150 m or less below the seabed was calculated to be 0-180 kPa using empirical formula (Li YL et al., 2017).

3.Decoupling the physical effects in the process of NGHs dissociation

The NGHs exploitation by depressurization involves four physical processes before and after NGHs dissociation,namely heat conduction, phase transition, multiphase seepage,and stress propagation.These four processes correspond to unique characteristic time.In the case of large differences in the characteristic time scales, the NGHs exploitation can be decoupled and the four processes can be sequentially analyzed in the order of slow to quick processes (Zhang XH et al.,2019).

The dimensionless characteristic time of heat conduction is as follows:

The dimensionless characteristic time of phase transition is as follows:

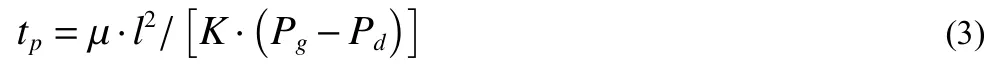

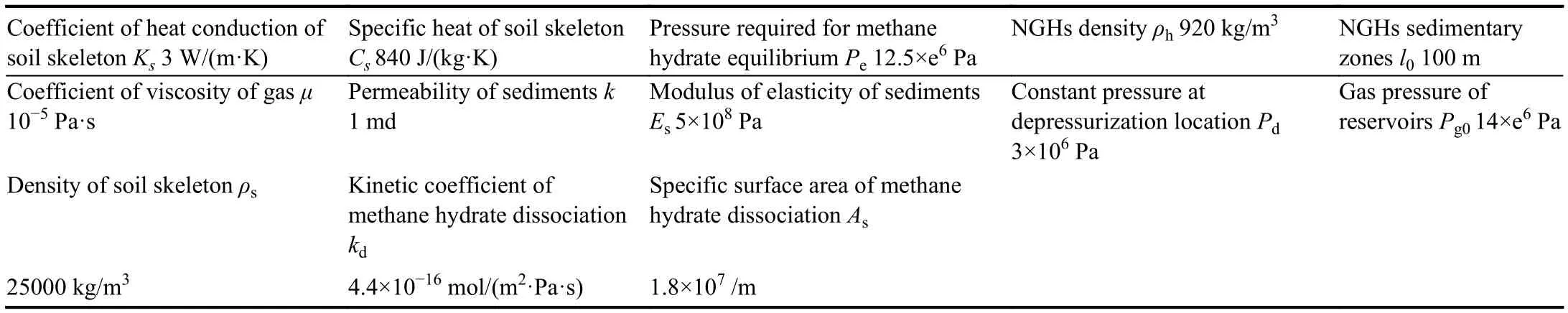

The dimensionless characteristic time of seepage is as follows:

The dimensionless characteristic time of stress is as follows:

The meanings and values of the parameters in these equations are listed in Table 1 (Zhang XH et al., 2019).

Table 1.Parameter values of decoupling.

Based on the data in Table 1, the ratio of the characteristic times of the four processes wastc:td:tp:ts=109:107:106:1,as calculated using the equations 1-4 (Zhang XH et al., 2019).Therefore, the stress propagation is the fastest, while the heat conduction is the slowest.Moreover, the four characteristic time scales show large differences, and thus the NGHs exploitation can be decoupled.According to the ratio, the NGHs dissociation-induced seepage can be first analyzed,followed by the calculation of the stratum deformation occurring in the NGHs exploitation by depressurization.

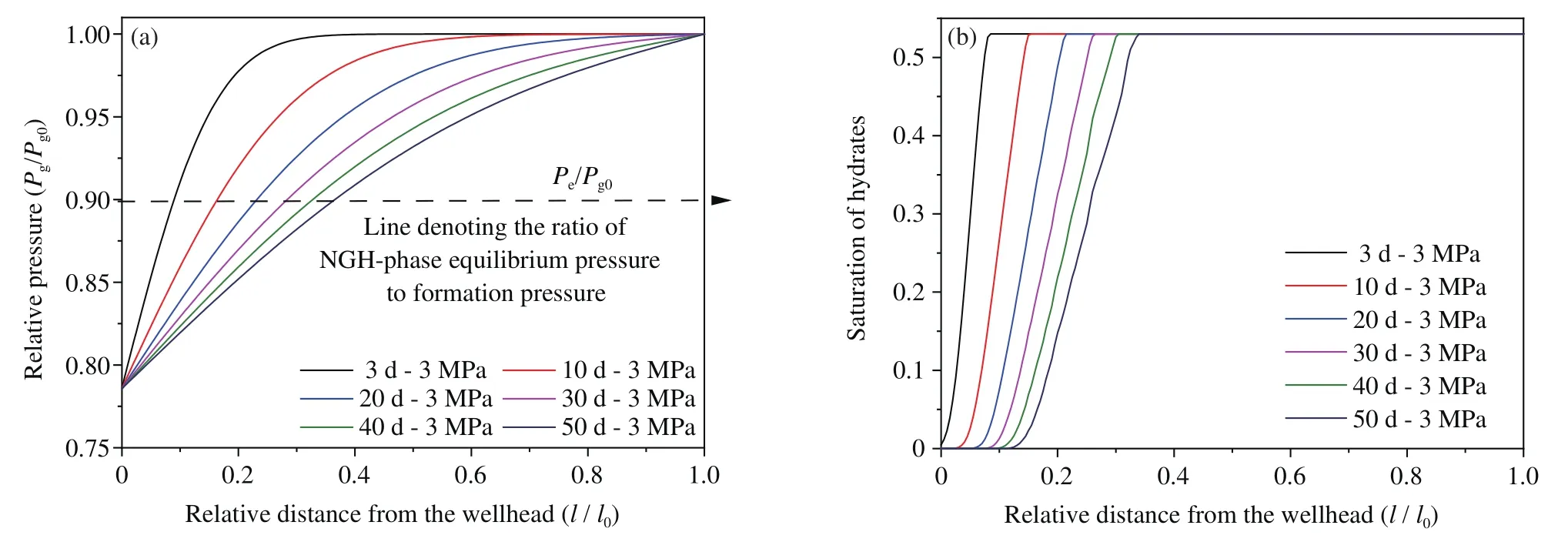

As shown in Fig.2 (Sun FF, 2019), a one-dimensional model of depressurization-induced dissociation in NGHs exploitation has been established based on the above decoupling process.Moreover, the pore pressure relative to the initial pore pressure and the saturation distribution at different dissociation times were analyzed under a simulated pressure decrease of 3 MPa.

Fig.2.Time-varying curves of NGHs saturation and pore pressure at different positions (after Sun FF, 2019).a-pore pressure at different positions under different dissociation times; b-NGHs saturation at different positions under different dissociation times.

Based on the relationships between the time of NGHs exploitation by depressurization and NGHs dissociation degree and range and that between mechanical parameters of strata and NGHs saturation, this study determined the mechanical parameters of strata after NGHs dissociation.Moreover, it simulated the stratum deformation after NGHs dissociation using the numerical simulation software FLAC3D.

4.Calculation model and parameters

4.1.Numerical calculation model

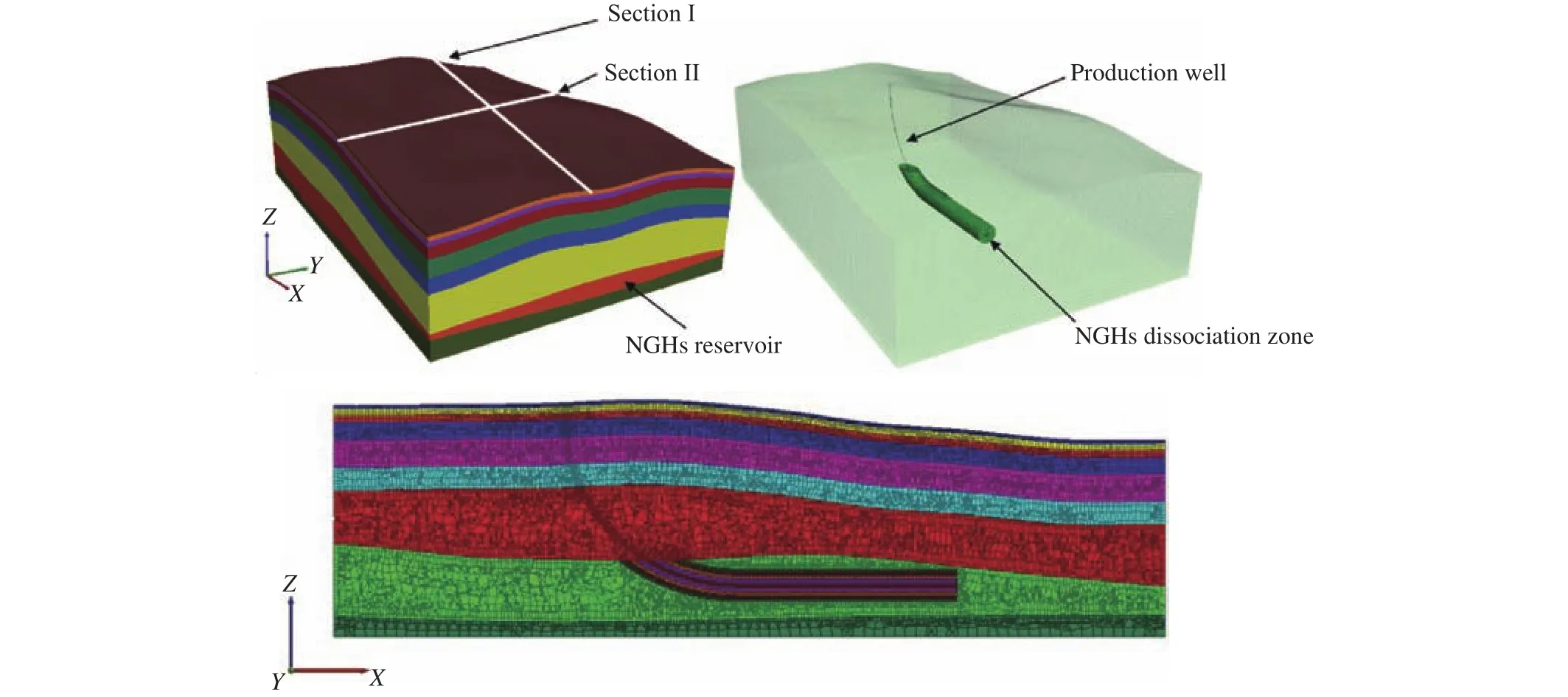

Software such as AutoCAD, Midas GTS NX, and FLAC3Dwas used to establish the physical simulation model.First, the surface contour map and the stratigraphic sections of the study area were obtained using AutoCAD, and then the stratigraphic data of the study area were extracted using the software.Next, information on strata and the locations of production wells was imported into Midas GTS NX—software for 3D geological modeling and analysis—to generate the stratum model.Finally, the production well model was established, and the NGHs dissociation zone was determined in the NGHs reservoir based on previous calculation results.As shown in Fig.3, the surface model of the study area was established based on the actual seabed terrain data, and the strata were divided according to the surveyed upper and lower interfaces of NGHs-bearing layers.As a result, the model consisted of seven overburden strata,one NGHs reservoir layer, and one bedrock layer.During NGHs exploitation, NGHs in the reservoir were dissociated along with the radial directions of a circle with the production well as the circle center after depressurization.Subsequently,parameters such as sediment strength in the NGHs dissociation zone would decrease.The simulated soil layers of the seabed had a length of 1200 m, a width of 800 m, and a height of approximately 360 m.Meanwhile, the NGHs production well in the model had a diameter of 10 cm.

Hybrid meshes were adopted for the overburden strata, the NGHs reservoir, the underlying strata, and the wellbore in the 3D model, and various soil layers of the wellbore were automatically grided according to reasonable mesh sizes.Fine meshes with small sizes were separately established for the zones such as the production well and the NGHs dissociation zone, while meshes with large sizes were adopted for their peripheral zones.In this way, the study area was modeled with high accuracy, while its peripheral zones, with little influence on simulation results but a large total volume, were modeled in a simplified manner.As shown in Fig.3, the model contained 3937598 units and 1957194 nodes.In this model, the boundaries of the NGHs reservoir were normally fixed to restrict its lateral displacement, the inclined bottom was fixed, and the top slope was a free surface.In addition,two observation sections, i.e., section I (y= 400 m) and section II (x= 600 m), were reserved in the model and were used to analyze the deformation effects and stress characteristics of the strata during NGHs dissociation.

Fig.3.Schematic diagram of the FLAC3D calculation model.

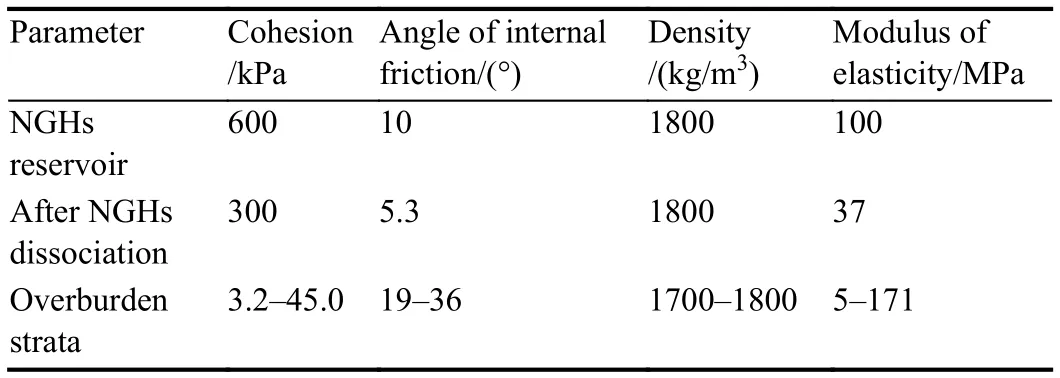

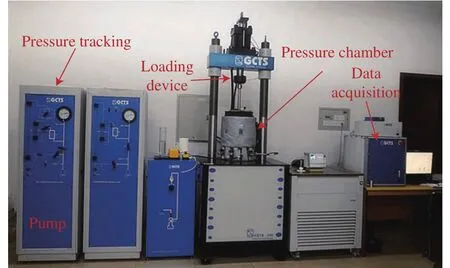

4.2.Calculation parameters and boundary conditions

The constitutive model based on the Mohr-Coulomb criterion was used for both the NGHs reservoir and its overburden strata.An elastic model was adopted for the production well made of steel.Meanwhile, an elastic model was also employed for the underlying soils based on geological survey data.The physical and mechanical parameters of sediments before and after the NGHs dissociation were determined based on existing study results and the indoor mechanical experiments of synthesis and dissociation conducted using the test system for the mechanical properties of NGHs-bearing sediments in the Institute of Mechanics, Chinese Academy of Sciences (Fig.4).Table 2 shows the test results of triaxial test for the calculations performed in this study.

Table 2.Parameter values for calculation.

Fig.4.Experimental devices for the synthesis, dissociation, and static and dynamic mechanical property measurement of NGHs-bearing sediments.

5.Calculated results and analysis

NGHs dissociation is the outward expansion process in the shape of a circle with the production well as the center.Section I in Fig 3 was a longitudinal section passing through the center of the NGHs dissociation circle.Therefore, this section had the largest displacement and thus was the most dangerous area.Section II in Fig 3 was a cross-section passing through the end of the horizontal section of the production well.Therefore, the calculation results of sections I and II were stated in detail in this study.

5.1.Stress characteristics

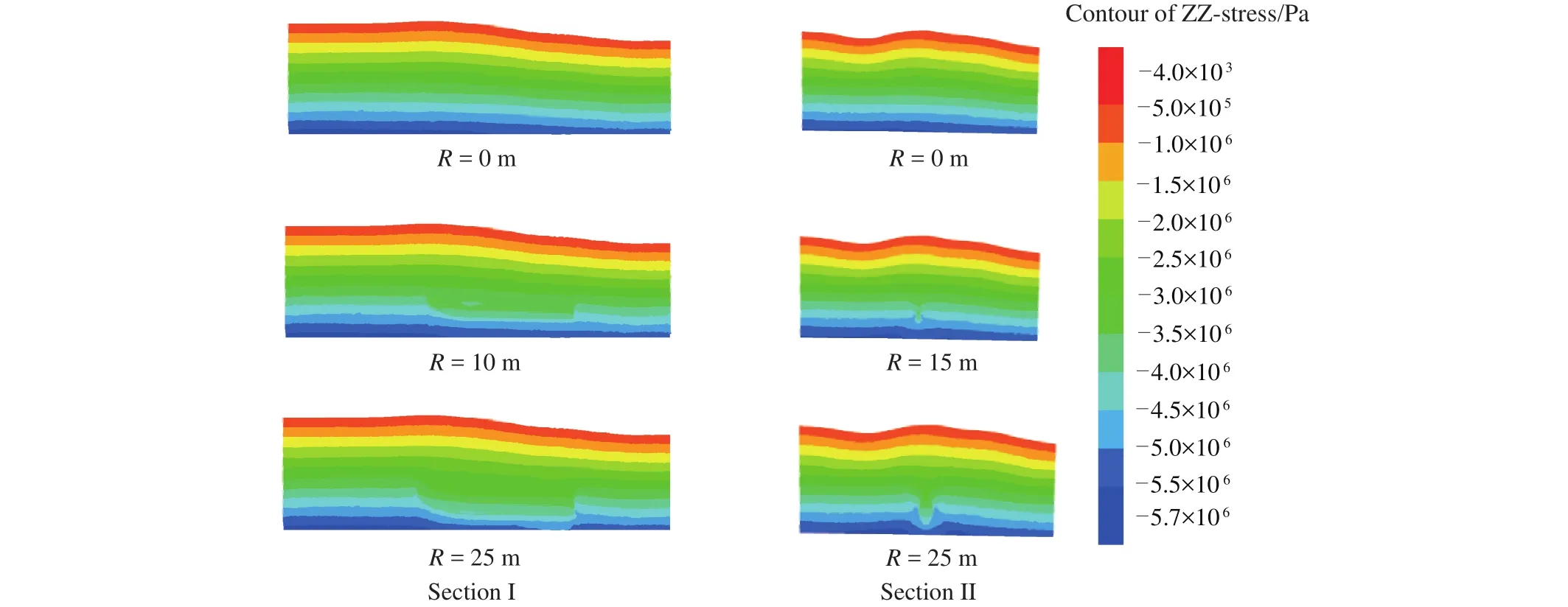

In this study, the dissociation degree of the NGHs reservoir was characterized by different radii (R) of the NGHs dissociation zone (also referred to as the dissociation radii).The distribution of the vertical stress in strata under different radii is shown in Fig.5.Specifically, after NGHs dissociation,the strength of soils decreased, and the surrounding soils ofthe production well underwent subsidence deformation via the action of the pressure and gravity of the overburden strata.As a result, the stress in the strata was redistributed.With the NGHs dissociation zone as the center, the strata showed a distinct, discontinuous stress distribution, whose influence range and degree increased with an increase in the dissociation radius.

Fig.5.Contour chart showing the distribution of vertical stress.

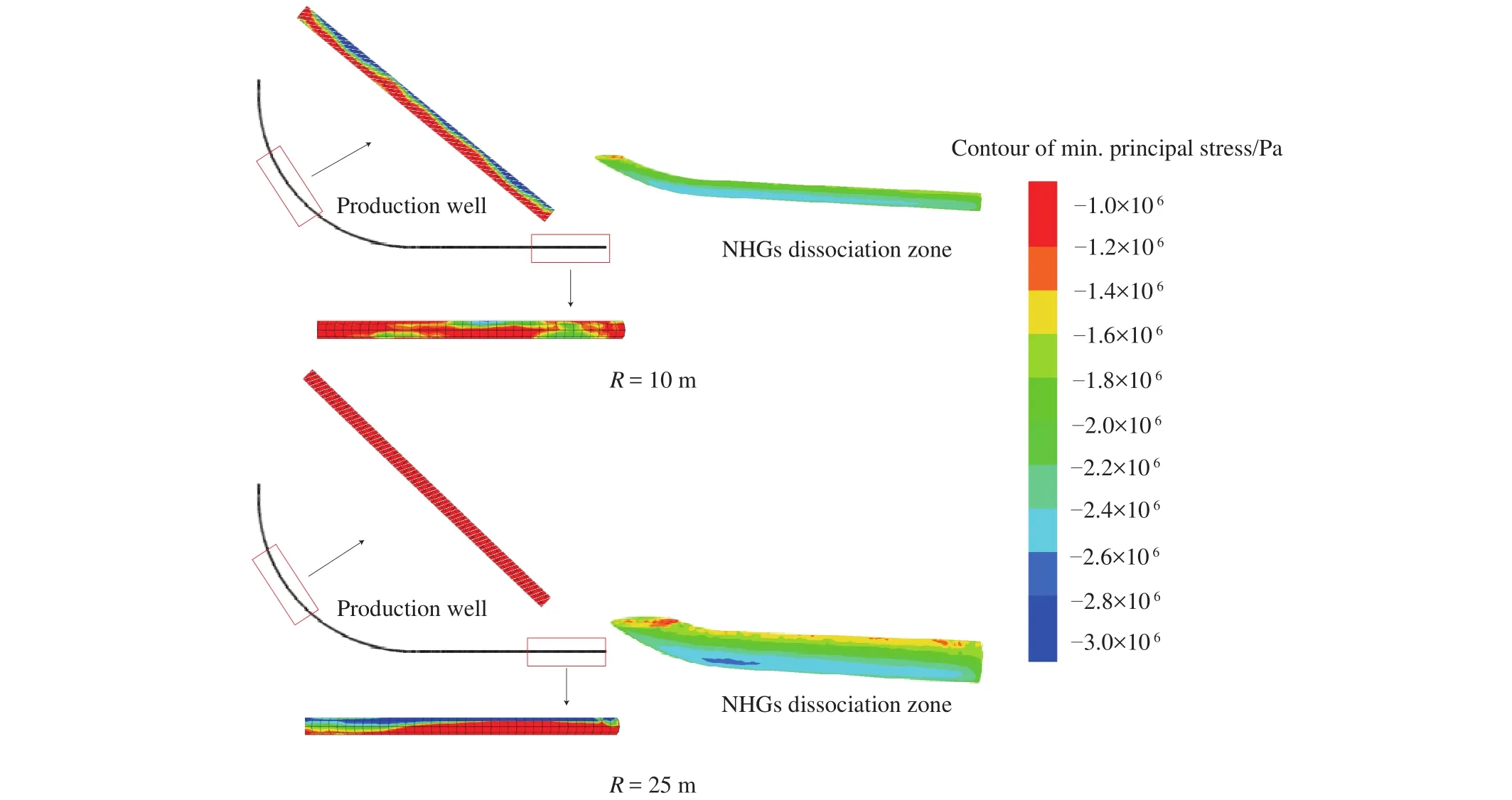

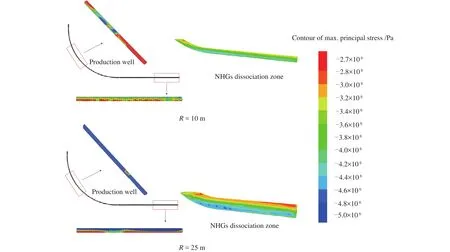

Besides the stress in seabed strata, the local stress in submarine structures and NGHs reservoirs is also the focus of NGHs production tests.During NGHs exploitation, the NGHs dissociation caused stratum deformation, the compression and consolidation of sediments in the NGHs dissociation zone,and the deformation of the production well.As a result, the stress in the NGHs dissociation zone and the production well zone was redistributed, as shown in Figs.6, 7.

Fig.6.Contour chart showing the minimum principal stress of local structures.

Fig.7.Contour chart showing the maximum principal stress in local structures.

The stress in the NGHs dissociation zone changed as follows.The stress at the zone boundaries noticeably changed and was concentrated locally with an increase in the dissociation radius.As the dissociation radius increased fromR= 10 m toR= 25 m, the maximum principal stress at the zone boundaries increased from 4.2 MPa to 4.8 MPa, while the minimum principal stress increased from 2.5 MPa to 2.8 MPa.The increased difference between the maximum and minimum principal stress would lead to an increase in shear stress.As a result, shear failure would be prone to occur.

The stress in the production well zone changed as follows.The interface between the NGHs reservoir and its overburden strata was a dangerous area.In particular, stress concentration tended to occur in the build-up section of the production well and was increasingly noticeable with an increase in the dissociation radius.When the dissociation radius increased fromR= 10 m toR= 25 m, the minimum principal stress of the build-up section decreased from 3 MPa to 1 MPa, while the maximum principal stress of this section increased from 2.7 MPa to 5 MPa.Owing to the significant increase in the shear stress, the production well zone was prone to suffer shear failure.

5.2.Deformation effects

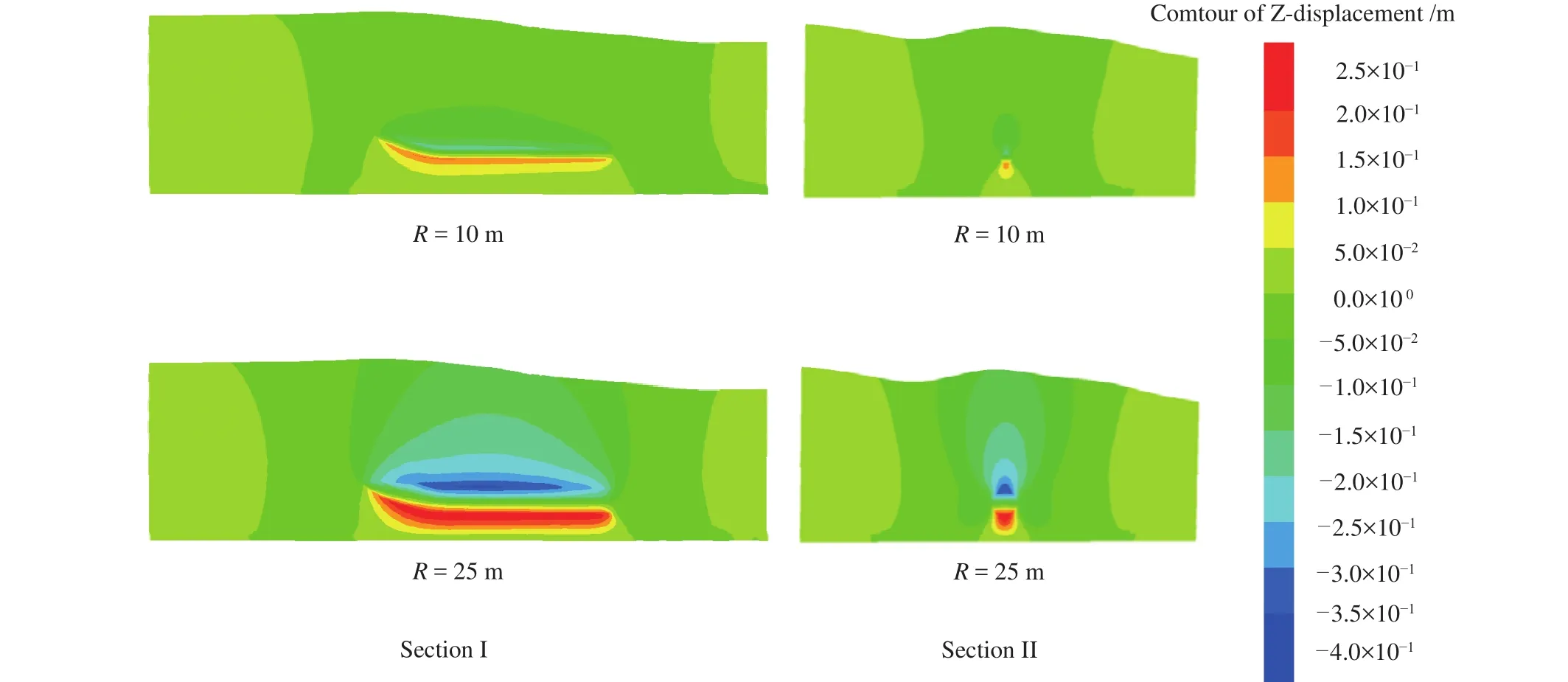

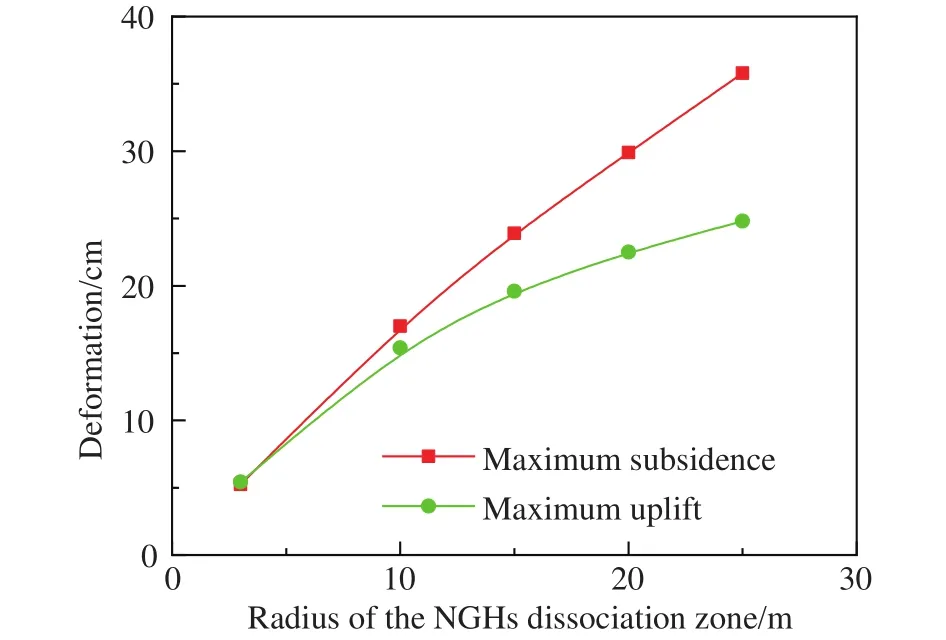

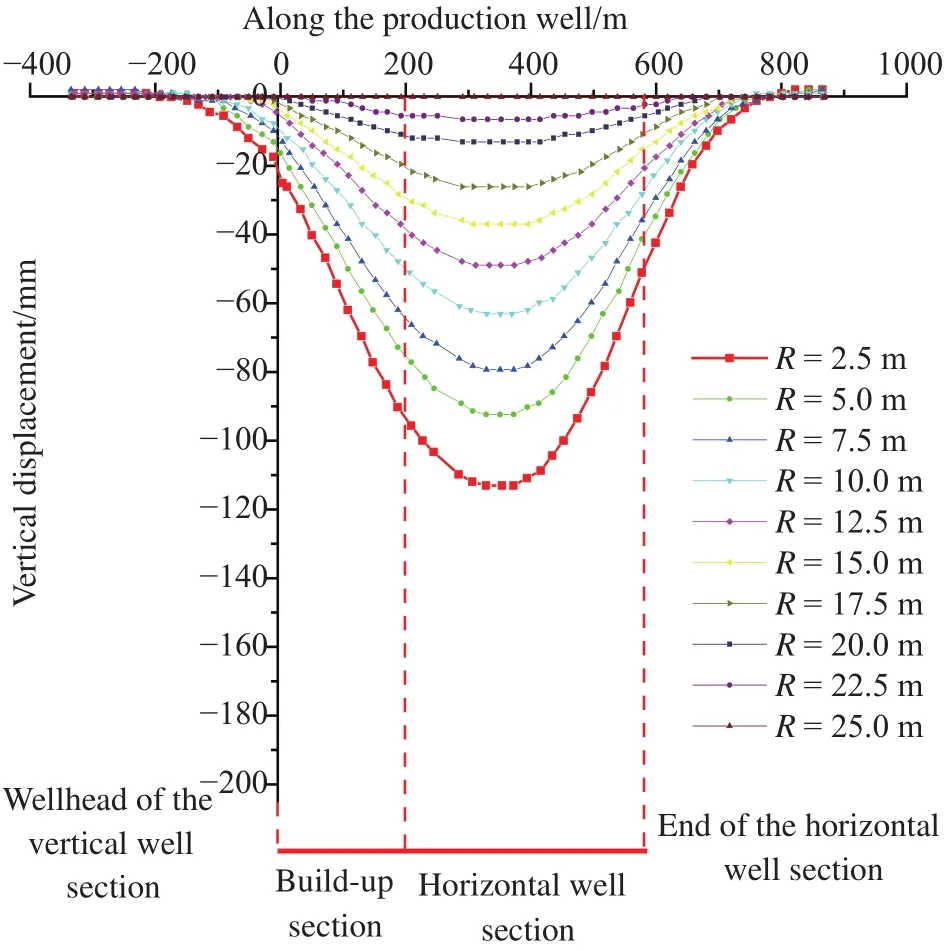

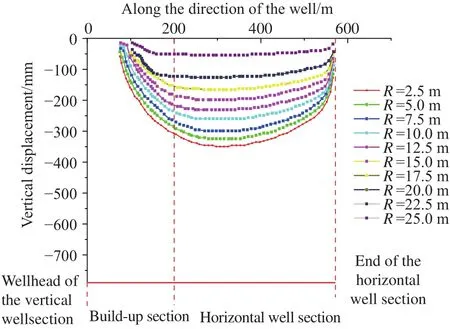

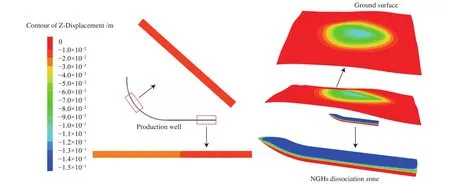

The evolutionary law of the stratum subsidence during NGHs exploitation can be determined by analyzing the deformation of the seabed surface and the strata at the upper interface of the NGHs dissociation zone under different radii of the NGHs dissociation zone.As shown in Figs.8-10, the overburden and underlying strata of the NGHs dissociation zone subsided and were uplifted, respectively.Owing to the noticeable stress concentration and the increased deviator stress in the NGHs dissociation zone, the overburden strata mainly subsided right above the dissociation zone, while the underlying strata were uplifted right below the dissociation zone.Moreover, the uplift range was slightly larger than the subsidence range.These phenomena corresponded to the discontinuous distribution of stress shown in Fig.5.The underlying strata had a high degree of consolidation, and the shear strength of the NGHs reservoir decreased after NGHs dissociation, which jointly led to the release of the stress in the underlying strata of the NGHs dissociation zone.As a result, the underlying strata were slightly unloaded and uplifted.With a gradual increase in the dissociation radius during the NGHs exploitation, the vertical displacement of the strata also gradually increased, and the uniform subsidence of the seabed surface gradually transitioned into funnel-shaped subsidence.

Fig.8.Contour chart showing the vertical displacement.

As shown in Figs.9-11, the maximum vertical displacement of the strata increased with an increase in the dissociation radius.The maximum subsidence around the production well under different radii of the NGHs dissociation zone all occurred at the upper interface of this zone, and there was an approximately linear relationship between the maximum subsidence and the dissociation radius.The maximum uplift also increased with an increase in the dissociation radius, with the increasing rate gradually decreasing.This occurred possibly because the underlying strata were constrained by both the overburden and the deep strata.The underlying strata were compressed and consolidated via the action of self-gravity induced stress,resulting in higher mechanical properties of the underlying strata than those of the overburden strata.Therefore, the uplift level of the underlying strata was lower than the compression level of the overburden strata.

Fig.9.Schematic diagram showing the development trend of the maximum vertical displacement.

Fig.10.Subsidence curves of seabed surface under different radii of the NGHs dissociation zone.

Fig.11.Subsidence curves of the upper interface of the NGHs dissociation zone under different radii of the NGHs dissociation zone.

The safe and stable casing structure of production wells is also the key to the safe and eco-friendly development of NGHs.As shown in Fig.12 and Fig.13, the production well also underwent subsidence and deformation due to the action of its surrounding soils during the NGHs dissociation process.When the dissociation radius was set atR= 10 m, the maximum subsidence of the seabed surface and the NGHs dissociation zone was 2.68 cm and 16.5 cm, respectively.By contrast, when the dissociation radius was set atR= 25 m, the maximum subsidence of the seabed surface, the NGHs dissociation zone, and the build-up section was 11.5 cm, 35.5 cm, and 2.5 cm, respectively.The large deviator stress caused large shear deformation, and the subsidence was concentrated at the interface between the NGHs reservoir and its overburden strata in the build-up section of the production well.

Fig.12.Contour chart showing the vertical displacement distribution in local structures under the dissociation radius of R = 10 m.

Fig.13.Contour chart showing the vertical displacement distribution in local structures under the dissociation radius of R = 25 m.

The production well showed a deformation far smaller than that of its surrounding soils due to its high strength.The soils surrounding the vertical section of the production well showed a small deformation and the vertical section was roughly fixed.The horizontal section of the production well moved downward due to the subsidence of its surrounding soils.As a result, end effects occurred at the end of the horizontal section.The build-up section, which connected the vertical and horizontal sections of the production well,underwent “positive” horizontal displacement and restricted the movement of soils on one side due to the combined effects of the fixed vertical section and the downward traction of the horizontal section.

As mentioned above, the deformation of the seabed surface and the NGHs dissociation zone increased with an increase in the dissociation radius, and the production well also underwent deformation under the action of its surrounding soils.Therefore, it is necessary to take corresponding measures during the NGHs exploitation to avoid damage to the submarine structures induced by seabed deformation.Furthermore, protective measures should be taken for the production well, especially at the interface between the NGHs reservoir and its overburden strata, to avoid damage to the production wells.

6.Conclusions

This study focuses on the stability of strata during the NGHs exploitation by depressurization.By using the FLAC3Dsoftware and combining the NGHs occurrence characteristics and with geomechanical parameters of the NGHs reservoir in the study area, this study conducted a numerical simulation of the stress and deformation effects of the overburden strata, the NGHs reservoir, and soils surrounding the horizontal well during the NGHs exploitation.The following conclusions can be drawn:

(i) In terms of the vertical deformation of the strata during the NGHs exploitation, the overburden and underlying strata of the production well subside and are uplifted, respectively,and then gradually stabilize.

(ii) With the dissociation of NGHs, subsidence funnels will form in the overburden strata.Therefore, it is necessary to take corresponding measures to avoid damage to submarine structures induced by stratum deformation.The upper interface of the NGHs dissociation zone shows large deformation and corresponding redistribution and discontinuity of stress.

(iii) In the case of a large dissociation radius, large vertical deformation will occur near the interface between the NGHs reservoir and its overburden strata in the build-up section of the production well.Moreover, apparent stress discontinuity will occur in the surrounding soils of this section, and distinct stress concentration will occur in the wellbore.Since these stress distribution characteristics are consistent with the deformation characteristics, shear failure is prone to occur.

(iv) Obvious end effects tend to occur at the end of the horizontal section of the production well, which may lead to the deformation and failure of the casing structure.Stress concentration will occur in the build-up section.Moreover,discontinuous stress and large deformation will occur in the surrounding soils of this section.As a result, the build-up section is prone to suffer shear failure.Therefore, it is necessary to take corresponding measures in the build-up sections and at the end of the horizontal sections of production wells to prevent damage and ensure the wellbore safety in the long-term NGHs exploitation.

CRediT authorship contribution statement

Qian-yong Liang and Xu-hui Zhang conceived of the presented idea, and designed the model and the computational framework.Lin Yang and Peng-fei Xie analysed the data and carried out the implementation.Liang-hua Zhang performed the calculations.Lin Yang and Peng-fei Xie wrote the manuscript with input from all authors.All authors discussed the results and contributed to the final manuscript.

Declaration of competing interest

The authors declare no conflicts of interest.

Acknowledgment

This study was funded by the Key Special Project for Introduced Talents Team of Southern Marine Science and Engineering Guangdong Laboratory (Guangzhou)(GML2019ZD0307), the gas hydrate program initiated by the China Geological Survey (DD20190218), and the project of the National Natural Science Foundation of China(11872365).

- China Geology的其它文章

- China achieved fruitful results in oil-shale gas-coalbed methane exploration and development in 2021

- Formation mechanism, experimental method, and property characterization of graindisplacing methane hydrates in marine sediment: A review

- Molecular simulation studies on natural gas hydrates nucleation and growth: A review

- Distributed optical fiber acoustic sensor for in situ monitoring of marine natural gas hydrates production for the first time in the Shenhu Area, China

- Experimental investigation of hydrate formation in water-dominated pipeline and its influential factors

- Application of wellhead suction anchor technology in the second production test of natural gas hydrates in the South China Sea