Optimization of manganese peroxidase production from Schizophyllum sp. F17 in solid-state fermentation of agro-industrial residues

Yue Zhou, Bing Yang, Yang Yang, and Rong Jia

College of Life Science, Anhui University, Hefei 230601, Anhui, China

Manganese peroxidase (MnP) (EC1.11.1.13) is an extracellular heme-containing glycoprotein produced by various basidiomycetous fungi and it can oxidize a variety of phenolic and non-phenolic substances, including lignin as well as a range of recalcitrate pollutants, such as chlorinated aromatic compounds, heterocyclic aromatic hydrocarbons,various dyes, and synthetic high polymers[1-2]. Due to the important degradative potential of MnP, there is a general interest in producing this enzyme through fermentation processes[3-4].

However, the cost of enzyme production is a challenge that could seriously limit the potential broad application of MnP[4]. In recent years,solid-state fermentation (SSF) has gained increasing interest because several studies have shown that SSF has the advantages of higher product yields, less wastage of water, and simpler downstream processing, when compared with submerged fermentation (SmF)[4-6]. Currently, SSF is accepted as the most economical process for ligninolytic enzyme production by fungi, because it can produce higher yield of enzyme using cheaper materials, such as agro-industrial wastes. Hence, in the present study, various lignocellulosic residues (rice hulls,pine sawdust, wheat bran, rice straw, and wheat straw) were screened as growth medium for the production of MnP. The advantages of carrying out SSF using these agricultural wastes include decrease in the cost of enzyme production, reduction in the quantity of solid waste, and increase in environmentfriendly management of agro-industrial wastes[3-4,7].

The white-rot fungusSchizophyllumsp. F17, a local organism isolated by our lab, has been previously shown to have the potential for dye decolorization and the ability to produce MnP when grown on agro-industrial residues[8-9]. Thus, the aim of the present study was to determine a suitable SSF mixed medium for MnP production bySchizophyllumsp. F17 from lignocellulosic residues,and optimize the ratio of the medium components by response surface methods (RSM) to obtain high MnP yield. After optimization, the production of MnP was enhanced and maximum enzyme activity was achieved on the sixth day of SSF.

1 Materials and methods

1.1 Strain, SSF substrate preparation,inoculation, and culture conditions

Schizophyllumsp. F17 was isolated from a decayed wood chip pile in the vicinity of Hefei, China.The fungus was cultured on potato dextrose agar (PDA)slants for one week at 28 ℃ . The grown mycelium mat,collected from several slants and washed with sterile water, was homogenized using a Waring blender.Subsequently, 500 mL flasks containing 200 mL of liquid medium were inoculated with 20 mL of mycelial suspension, and the flasks w ere incubated at 28on a rotary shaker at 120 r/minfor 3 d. The homogenized mycelia obtained from the crushed mycelial pellets were inoculated into 500 mL Erlenmeyer flasks containing 20 g of SSF substrate designed by MINITAB 15 software and 2 0 mL of water (the water holding capacity was 1 mL/g(water per dry medium)),and the flasks were incubated at 28for 6 d.

1.2 Experimental designs and data analysis

RSM are widely applied in the optimization and modeling of the fermentation process. They provide important information regarding the optimum level of each variable, along with its interactions with other variables[3]. In the present study, several kinds of lignocellulosic residues such as rice hulls, pine sawdust, wheat bran, rice straw, and wheat straw were screened using RSM to obtain the optimum medium components influencing MnP production in the SSF, and the important factors as well as their optimal levels were evaluated. The experimental plan was developed by adopting the Plackett-Burman factorial design and the Extreme-Vertices design with MINITAB software. SPSS (version 15.0)was used for regression analysis of the experimental data, and analysis of variance (ANOVA) was employed to estimate the statistical parameters.

1.3 Enzyme assay

MnP activity was determined by the increase in absorbance at 240 nm based on the oxidation of Mn2+to Mn3+[8]. One unit (U) of MnP activity was defined as the oxidization of 1 μmol of Mn2+per minute at 25 ℃, and the activity was expressed as U per g dry residue (substrate plus mycelium) (U/g).Experiments were performed in triplicate, and the results were expressed as the mean values.

2 Results and discussion

2.1 Effect of medium components on MnP production

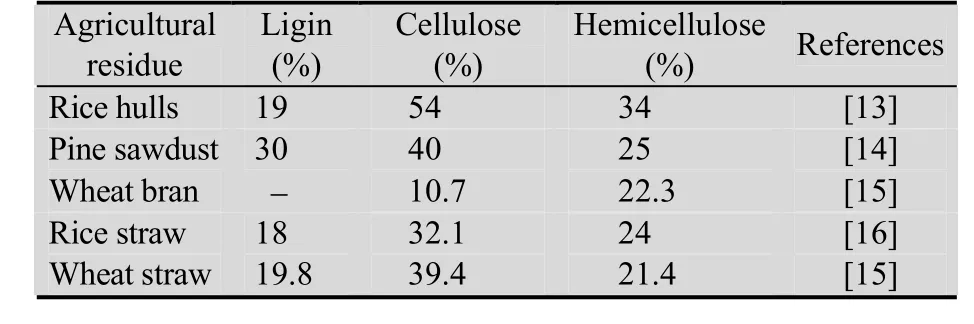

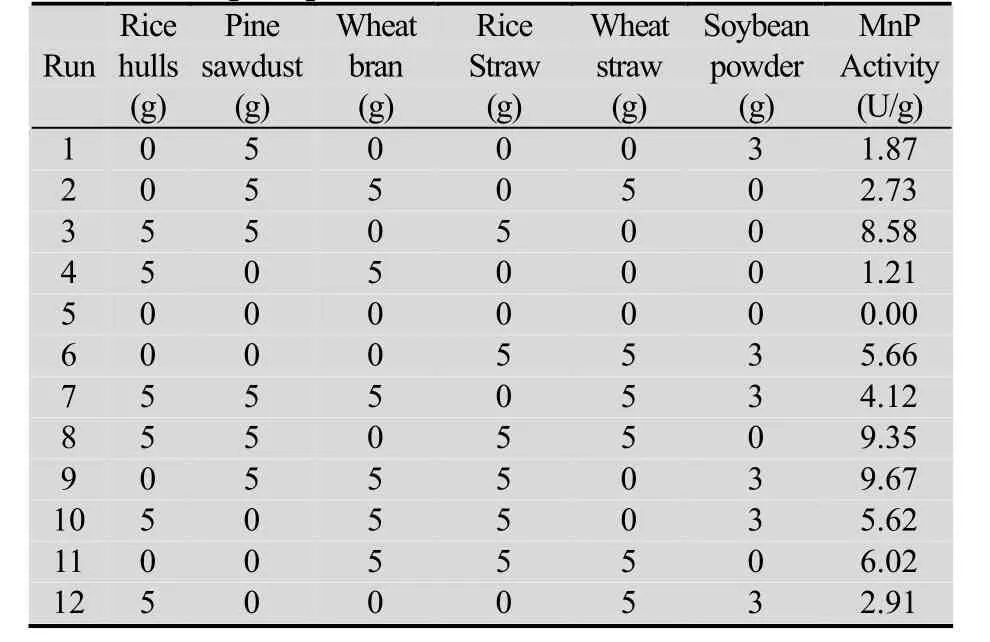

Although MnP production from fungi is influenced by many parameters such as species, type of cultivation, culture medium, and time, the medium components are the critical factors[10-12]. Table 1 shows the chemical composition of several agricultural residue employed in the present work. Rice hulls, pine sawdust, wheat bran, rice straw, wheat straw, and soybean powder as substrates for the growth ofSchizophyllumsp. F17 and production of MnP were investigated using Plackett-Burman design. Accordingly,12 experiments were carried out (Table 2).

By applying multiple regression analysis, the predicted MnP activity (MPA)was obtained from Eq. (1):MPA=?0.155+0.195A+0.497B+0.033C+1.069D+0.128E+0.109F.

whereA: rice hulls;B: pine sawdust;C: wheat bran;D: rice straw;E: wheat straw; andF: soybean powder.

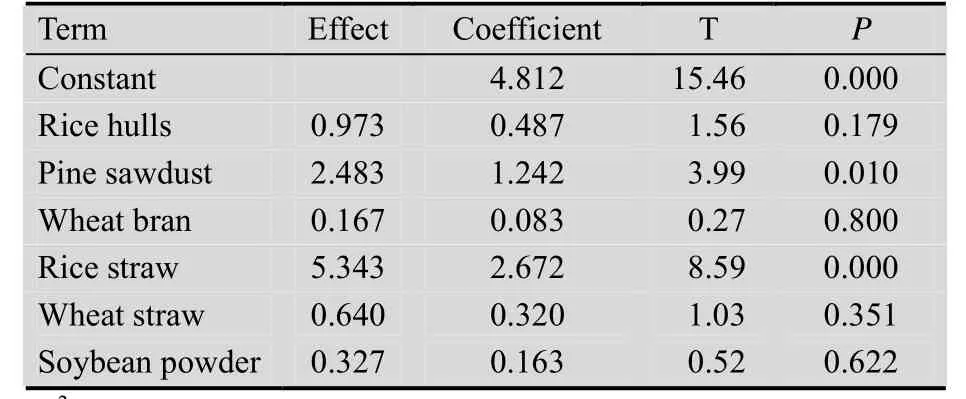

The statistical significance of the variables in the above-mentioned model (Eq. (1)) was examined byt-test andP-test (Table 3). TheP-values given in Table 3 show that pine sawdust and rice straw had greater effects on MnP activity than the other factors. The coefficient of determination (R2;94.92%), which indicates the reliability of the model, demonstrated that the model was consistent with the experiment results.

Table 1 Chemical composition of some agricultural residue used for MnP production

Table 2 Experimental design and results of Plackett-Burman design experiment (MINITAB software)

Table 3 Estimated regression coefficients for Eq. (1)

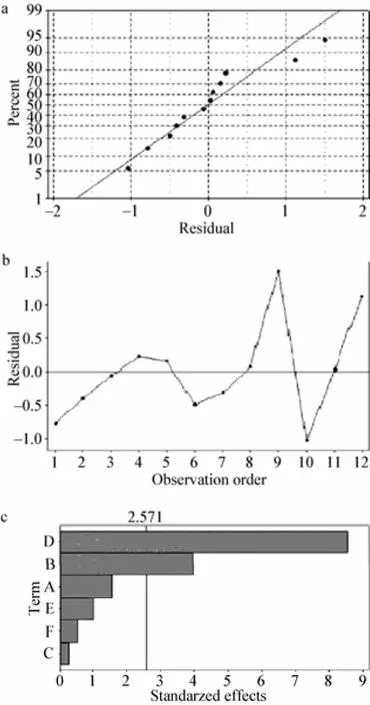

Residual plot was used for further analysis of the model. The residual normal probability figure (Fig. 1a)showed that the residual distribution conformed to the normal distribution, implying that the experiment results were positively correlated with the predictions.In Fig. 1b illustrating the residual distribution, the activities of MnP were randomly distributed on both sides of the zero value, indicating that the order of the test had no effect on the results; thus, each value of the results was independent and valid. On the other hand,the most important medium components were tested by Pareto analysis which is based on the notion that, for many events, roughly 80% of the effects come from 20% of the causes. As shown in Fig. 1c, the Pareto Chart indicated that pine sawdust and rice straw were the most important factors influencing MnP activity,which was noted to be consistent with the result ofP-test.

Fig. 1 Residual Plots for Eq.1 and pareto chart for the effect of each variable. (a) The residual normal probability plot of Eq. 1,the normal probability plot produced an approximately straight line, demonstrating the points conformed to a normal distribution.(b) The residual distribution plot of Eq. (1), the points were randomly distributed in both sides of zero value, indicating each value of the result was independent and valid. (c) Pareto chart for the effects of the variables, A: rice hulls; B: pine sawdust; C:wheat bran; D: rice straw; E: wheat straw; F: soybean powder; B and D had a significant effect on MnP activity.

2.2 Determination of the ratio of SSF medium components

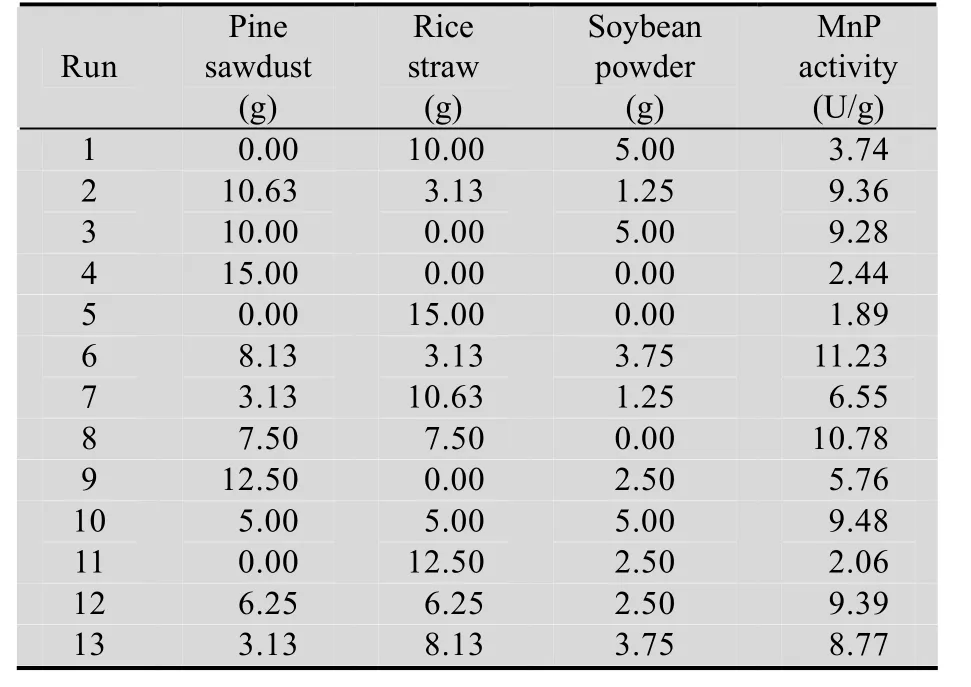

After determining the key factors affecting MnP activity, the ratio of the medium components was optimized using RSM to obtain high MnP yield. Pine sawdust and rice straw were used as the main factors to determine the ratio of SSF medium components. As soybean powder is rich in nitrogen and mineral elements, allowing efficient growth of fungal hyphae in a shorter period of fermentation, it was also considered as a medium component and examined by RSM for high MnP yield. The Extreme-Vertices design of mixture experiment was adopted to study the effect of these nutrient substrates (pine sawdust, rice straw,and soybean powder) on MnP fermentation. The experimental matrix and results are given in Table 4.

By applying multiple regression analysis, a second-order polynomial prediction equation was derived as follows (Eq. (2)):

MPA=0.171A+0.107B+1.247C+0.151AB+0.028AC?0.074BC.

whereA: pine sawdust;B: rice straw; andC:soybean powder.

In addition,t-test andP-test were also used to examine the statistical significance of the factors in the model (Eq. (2)). The results showed that the term AB(pine sawdust×rice straw) in Eq. (2) was significant at the 1% level, implying that the interaction between pine sawdust and rice straw had a significant impact on MnP activity, while the other two terms (AC and BC)were not significant. Using ANOVA, anR2value of 0.972 3 was obtained, which confirmed that the equation was highly reliable.

Subsequently, residual plot was also used to further examine the model. The MnP activities obtained (Table 4) were positively correlated with the predictions and each value of the results was noted to be independent and valid according to the residual plot (data not shown).

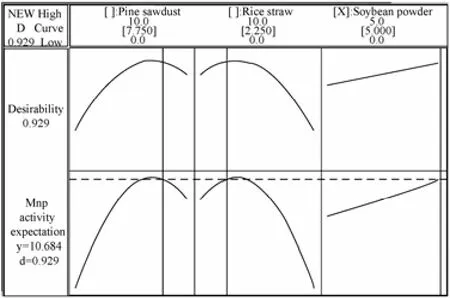

Furthermore, the effects of pine sawdust, rice straw, and soybean powder on MnP activity were also investigated using the response surface plot. Fig. 2 illustrates that the expected MnP activity was 10.68 U/g, and that the optimized ratio of pine sawdust, rice straw, and soybean powder was 0.52:0.15:0.33. In addition, the desirability of the experiment was 0.929, indicating that the optimized ratio of the medium components can achieve the anticipated target of the experiment.

Following the optimization of mixture medium to produce MnP, the enzyme activity in the optimized medium was recorded from the third day on a daily basis, and the results showed that the peak of MnP activity (11.18 U/g) appeared on the sixth day of fermentation.

The maximum MnP yield achieved in the present study was observed to be about 6.5 times higher than that obtained through the SSF of eucalyptus residue(1.7 U/g) by Arantes et al[17]. On the other hand,Gassara et al[4]achieved a higher yield of MnP using agro-industrial wastes different from those employed in the present study. Nevertheless, the medium with natural pH used in the current study is easily available and economical. Also, some important fermentation parameters including incubation temperature, inoculum size, moisture content and particle size should be further optimized in the next step for maximum yield of MnP production. Thus, the above-mentioned results indicate that agro-industrial materials such as pine sawdust and rice straw are suitable feedstock for the production of high-quality MnP bySchizophyllumsp. F17.

Table 4 Experimental design and results of extreme vertex design experiment (MINITAB software)

Fig. 2 Response surface plot showing MnP activity with the optimized medium. A maximum activity of MnP was achieved from the mixed media which contained 7.75 g pine sawdust,2.25 g rice straw and 5 g soybean powder. The desirability of experiment was 0.929.

In this investigation, a comparison of the various agricultural wastes on the production of MnP bySchizophyllumsp. F17 revealed that the optimized ratio combination of pine sawdust, rice straw, and soybean powder has the greatest effect, with 3.6-fold and 4.9-fold increases of enzyme activity, respectively, compared with the culture grown on medium with only pine sawdust or rice straw (Table 4). The major component of pine sawdust and rice straw is cellulose, followed by hemicellulose or lignin (Table 1). Cellulose and hemicelluloses are macromolecules constructed from different sugars; whereas lignin is an aromatic polymer synthesized from phenylpropanoid precursors. The composition and proportions of these compounds vary between plants. Lignocellulosic residues are rich in carbon content and other vital nutrients essential for fungal growth. Pine sawdust is not only a significant carbon source, but also an important inducer for ligninolytic enzymes production by white-rot fungi. Rice straw has a rich cellulosic composition and has been used as the substrates to screen for novel fungus with powerful delignification capability[18]. Soybean powder utilized in this study is rich in nitrogen content, vitamins and other nutrients for medium, and when added to pine sawdust and rice straw, it improves the C-N sources,presenting ideal conditions for fungal growth and enzyme production. So, presumably, the production of MnP activity may be dependent on the type of used substrate, owing to the differences in chemical compositions and structure, also, the combined C, N sources of different kinds of agricultural wastes can improve the production of ligninolytic enzymes.

3 Conclusion

The present study examined the feasibility of MnP production from white-rot fungi by using agro-industrial residues as the SSF medium. Solid-state medium comprising pine sawdust, rice straw, and soybean powder at a certain ratio was found to be suitable for MnP production bySchizophyllumsp. F17.The use of mixed agro-industrial residues as the SSF medium for producing MnP considerably lowered the production cost, making this enzyme a potential candidate for industrial application.

[1]Praveen K, Usha KY, Viswanath B, et al. Kinetic properties of manganese peroxidase from the mushroomStereum ostreaand its ability to decolorize dyes. J Microbiol Biotechnol, 2012,22(11): 1540?1548.

[2]Martin H. Review: lignin conversion by manganese peroxidase(MnP). Enzyme Microb Technol, 2002, 30(4): 454–466.

[3]Vassilev N, Requena AR, Nieto LM, et al. Production of manganese peroxidase byPhanerochaete chrisosporiumgrown on medium containing agro-wastes/rock phosphate and biocontrol properties of the final product. Ind Crop Prod, 2009,30(1): 28?32.

[4]Gassara F, Brar SK, Tyagi RD, et al. Screening of agro-industrial wastes to produce ligninolytic enzymes by Phanerochaete chrysosporium. Biochem Eng J, 2010, 49(3): 388?394.

[5]Barrios-González J. Solid-state fermentation: Physiology of solid medium, its molecular basis and applications. Process Biochem, 2012, 47(2): 175?185.

[6]Rodríguez-Fernández DE, Rodríguez-León JA, Carvalho JC,et al. The behavior of kinetic parameters in production of pectinase and xylanase by solid-state fermentation. Bioresour Technol, 2011, 102(22): 10657?10662.

[7]Landolo D, Amore A, Birolo L, et al. Fungal solid state fermentation on agro-industrial wastes for acid wastewater decolorization in a continuous flow packed-bed bioreactor.Bioresour Technol, 2011, 102(16): 7603?7607.

[8]Cheng X, Jia R, Li P, et al. Purification of a new manganese peroxidase of the white-rot fungusSchizophyllumsp. F17, and decolorization of azo dyes by the enzyme. Enzyme Microb Technol, 2007, 41(3): 258?264.

[9]Tang W, Jia R, Zhang D. Decolorization and degradation of synthetic dyes bySchizophyllumsp. F17 in a novel system.Desalination, 2011, 265(1/3): 22?27.

[10]Hatvani N, Mecs I. Effect of the nutrient composition on dye decolorisation and extracellular enzyme production byLentinus edodeson solid medium. Enzyme Microb Technol,2002, 30(3): 381?386.

[11]Majeau J-A, Brar SK, Tyagi RD. Laccases for removal of recalcitrant and emerging pollutants. Bioresour Technol, 2010,101(7): 2331?2350.

[12]Levin L, Melignani E, Ramos AM. Effect of nitrogen sources and vitamins on ligninolytic enzyme production by some white-rot fungi. Dye decolorization by selected culture filtrates.Bioresour Technol,2010, 101(12): 4554?4563.

[13]Orlando US, Baes AU, Nishijima W, et al. Preparation of agricultural residue anion exchangers and its nitrate maximum adsorption capacity. Chemosphere, 2002, 48(10): 1041?1046.

[14]Wang ZY, Cao JQ, Wang J. Pyrolytic characteristics of pine wood in a slowly heating and gas sweeping fixed-bed reactor.J Anal Appl Pyrolysis, 2009, 84(2): 179?184.

[15]Zhou XH, Chen HZ, Li ZH. Experimental observation on cellulosic biodegradation in solid state fermentation. Chin J Process Eng, 2003, 3(5): 447?452 (in Chinese).周曉宏, 陳洪章, 李佐虎. 固態(tài)發(fā)酵中纖維素基質(zhì)降解過程初步研究. 過程工程學(xué)報, 2003, 3(5): 447?452.

[16]Sánchez C. Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol Adv, 2009, 27(2): 185?194.

[17]Arantes V, Silva E, Milagres A. Optimal recovery process conditions for manganese peroxidase obtained by solid-state fermentation of eucalyptus residue usingLentinula edodes.Biomass Bioenergy, 2011, 35(5): 4040?4044.

[18]Chang AJ, Fan JY, Wen XH. Screening of fungi capable of highly selective degradation of lignin in rice straw. Int Biodeterior Biodegrad, 2012, 72: 26?30.